Operation, Speed selection – Black & Decker 9400 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Speed Selection

The five speeds of which your drill press is capable will handle almost any

drilling project you may encounter. Generally speaking, you should use lower

speeds for drilling in metals and higher speeds for drilling in wood and wood

compositions^^Use the Speed Selection Chart as a guide in determining the

best drilling speed for your application. Always experiment in scrap material if

possible.

As a general rule you should drill pilot holes for metal drilling (except

when using hole saws). Also use cutting oil with most metals except case iron

and brass which should be drilled dry.

When using a twist bit for drilling wood or wood compositions, it will be

necessary to pull the bit from the hole frequently to clean chips from the flutes.

Care should be exercised when drilling plastics to avoid melting them.

ALWAYS CLAMP THE WORKPIECE.

ALWAYS WEAR EYE PROTECTION.

Material

Being Drilled

Type of

Drill Bit

Speed Setting

#9400

Comments

Metal: Ferrous

& Non-Ferrous

High speed

Steel Twist Bit

620 or 1100

RPM

Generally the low speeds

are best for drilling metal.

Metal: Ferrous

& Non-Ferrous

Hole Saw

620 or 1100

RPM

Generally lower speeds are

best. Hole saws are noisy.

Ceramics,

Masonry, Glass

Carbide Bit

620 RPM

Use very low speeds and

light pressure.

Plastics &

Laminates

High Speed

Steel Twist Bit

620 or 1100

RPM

Use care to avoid melting.

Plastics &

Laminates

Hole Saw

620 or 1100

RPM

Use care to avoid melting.

Wood & Wood

Compositions

High Speed

Steel Twist Bit

1720, 2340 or

3100 RPM

Remove bits from hole

often to remove chips.

Wood & Wood

Compositions

All Other Bits

(Spade, Auger,

Hole Saw)

1720, 2340 or

3100 RPM

SPINDLE RPM

CHUCK

MOTOR

3100 Muni

2340

■■■■1 ■■■■■■■■

1720 HBHIHII BBHHHHI

1100

■■■■■■■■■ ■■■■I

620

—

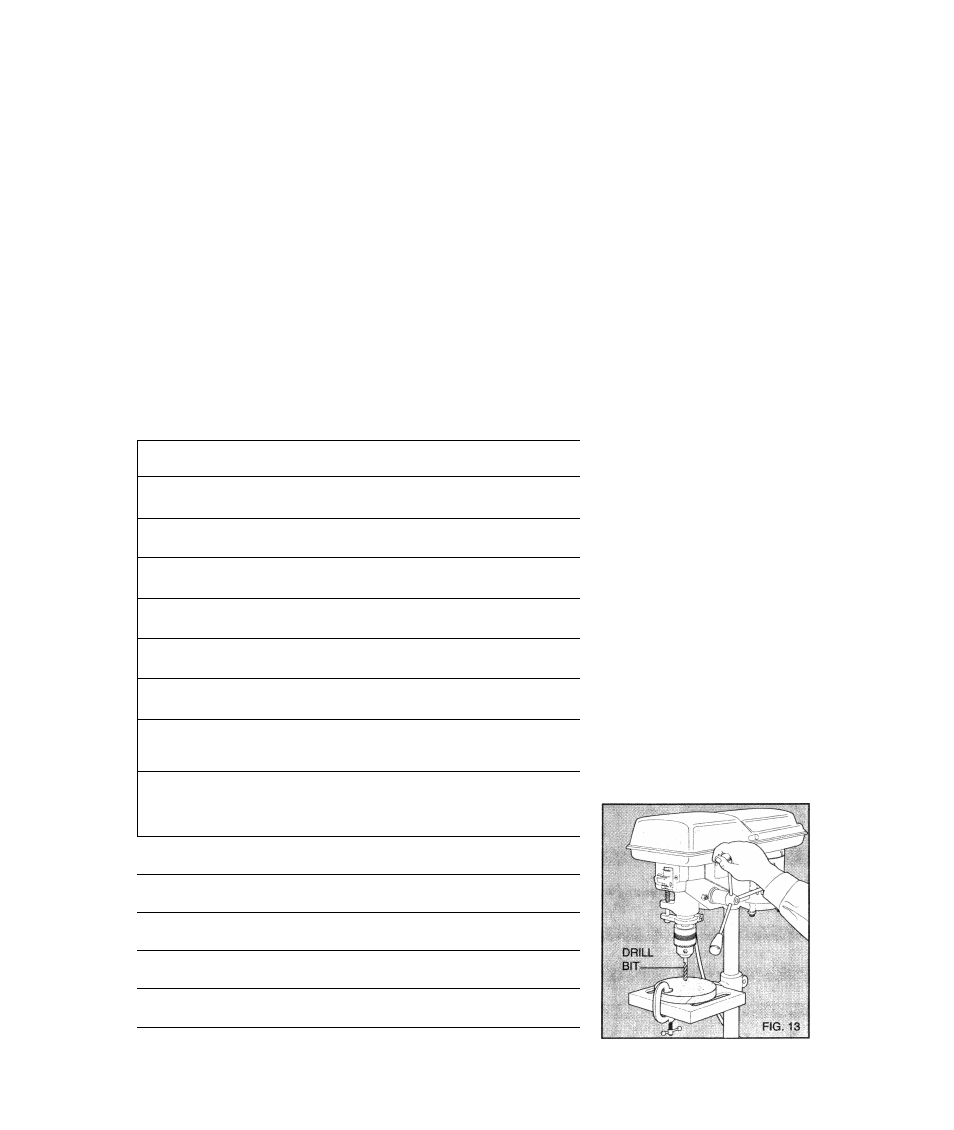

Operation

ALWAYS WEAR EYE PRO

TECTION. TURN OFF AND

UNPLUG DRILL PRESS WHEN

MAKING ANY ADJUSTMENTS.

These four steps constitute the

actual drilling of a hole. Before you

start step 1, select the proper speed,

set the drilling depth control, position

the work table so that the desired

drilling depth can be attained (not

too low), and centerpunch the

position of the hole to be drilled.

Drill in the center of the Work

Table so that the drill bit will pass

harmlessly through the clearance

hole.

1. Clamp Work — Always clamp

the workpiece to the Work Table

or other supporting surface. Use

“C” clamps, bar clamps, cinch

clamps or any other device you

can find to solidly anchor the

workpiece.

2. Insert the desired drill bit into

the chuck as far as it will go and

then pull it back out about 1/16".

Tighten the chuck with the key

in all three holes. (It is important

to tighten in all three holes.)

3. Make sure that the switch is

OFF and plug the tool in. Turn

the drill ON.

4. Using one of the three handles,

lower the drill bit into the

workpiece, as shown in Figure

13.