Grounding, Instructions, Motor – Black & Decker 9400 User Manual

Page 4: Lubrication & maintenance, Unpacking your drill press, Grounding instructions

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Grounding

Instructions

ALL GROUNDED, CORD-

CONNECTED TOOLS: In the event

of a malfunction or breakdown,

grounding provides a path of least

resistance for electric current to

reduce the risk of electric shock.

This tool is equipped with an electric

cord having an equipment-grounding

conductor and a grounding plug.

The plug must be plugged into a

matching outlet that is properly

installed and grounded in accor

dance with all local codes and

ordinances.

Do not modify the plug pro

vided—If It will not fit the outlet, have

the proper outlet installed by a

qualified electrician.

Improper connection of the

equipment-grounding conductor can

result In a risk of electric shock. The

green (with or without yellow stripes)

is the equipment-grounding conduc

tor. If repair or replacement of the

electric cord is necessary, do not

connect the equipment-grounding

conductor to a live terminal.

Check with a qualified electri

cian or serviceman if the grounding

instructions are not completely

understood, or if in doubt as to

whether the tool Is properly

grounded.

Use only 3-wire extension cords

that have 3-prong grounding plugs

and 3-pole receptacles that accept

the tool’s plug.

Repair or replace damage or

worn cords Immediately.

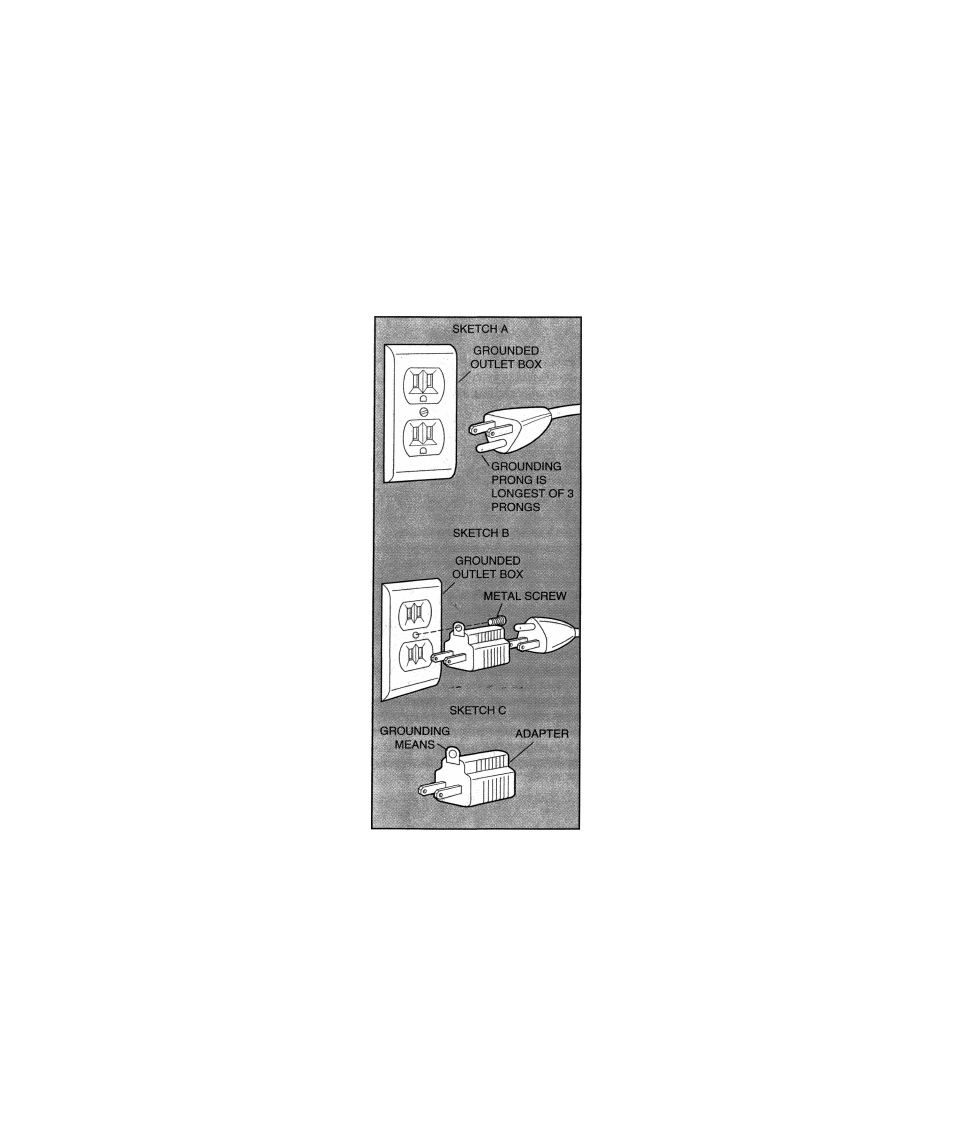

GROUNDED, CORD-

CONNECTED TOOLS INTENDED

FOR USE ON A SUPPLY CIRCUIT

HAVING A NOMINAL RATING

LESS THAN 150 VOLTS: This tool

Is Intended for use on a circuit that

has an outlet that looks like the one

illustrated in Sketch A. The tool has

a grounding plug that looks like the

plug illustrated in Sketch A. A

temporary adapter, which looks like

the adapter Illustrated In Sketches B

and C, may be used to connect this

plug to a 2-pole receptacle as shown

in Sketch B if a properly grounded

outlet (Sketch A) is not available.

The green-colored rigid ear, lug, etc.

extending from the adapter must be

connected to a permanent ground

such as a properly grounded outlet

box. The temporary adapter should

be used only until a properly

grounded outlet (Sketch A) can be

installed by a qualified electrician.

Adaptor shown in sketches B & C is

not for use in Canada.

Motor

Be sure your power supply

agrees with the nameplate marking.

120 volts 50/60 Hz means alternating

current (normal 120 volt, 60 Hz

house current). A voltage decrease

of more than 10% will cause loss of

power and overheating. All B&D

tools are factory tested; if this tool

does not operate, check the power

supply.

Lubrication &

Maintenance

Permanently lubricated ball

bearings are used throughout your

Drill Press and periodic lubrication is

not required. In the unlikely event

that your Drill Press should ever

require service, take it to your local

Black & Decker Service Center or

other qualified service facility.

Service Center addresses are listed

on the owner’s registration card

packed with your tool. Do not

attempt to repair the tool yourself.

There are no user-serviceable parts

inside.

A film of any light machine oil on

the unpainted parts of your Drill

Press will prevent surface rust from

forming.

IMPORTANT:

YOUR DRILL PRESS IS

DRIVEN BY A RUBBER BELT. IF

THIS BELT IS EXCESSIVELY

TIGHT ON ITS PULLEYS AND A

PARTICULARLY LARGE DRILL

BIT IS USED, THERE EXISTS THE

POSSIBILITY OF A MOTOR

OVERLOAD WHICH WILL SERI

OUSLY DAMAGE YOUR MOTOR.

WHEN ADJUSTING THE

RUBBER BELT, MAKE IT TIGHT

ENOUGH TO REMOVE MOST OF

THE SLACK BUT MAKE SURE

THAT IT’S ABLE TO SLIP

ENOUGH ON THE PULLEYS TO

PREVENT A MOTOR OVERLOAD

CONDITION.

Unpacking Your Drill

Press

Your new drill press carton

contains the four main elements of

your drill press, plus the hardware

needed to assemble it. Each of the

four main elements is wrapped in a

plastic bag and placed in its own

pocket in the foam carton liner.

The four main elements of your drill

press are:

1. The Motor and Drive Unit