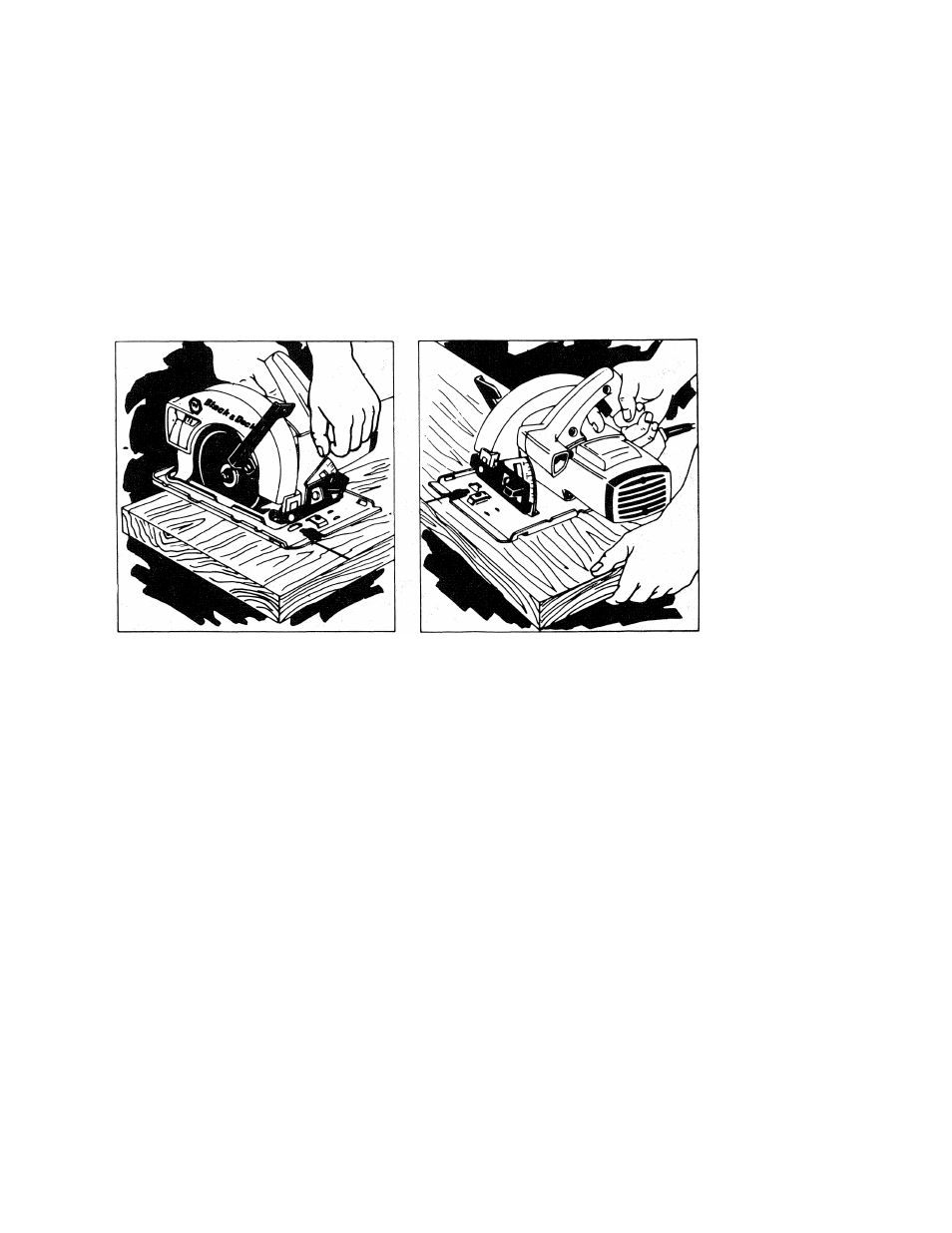

Operation, Fig. 10 - wrong – Black & Decker cat 3027-90 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION

WARNING: It is important to support the work properly and to hold the saw

firmly to prevent loss of control which could cause personal injury.

ALWAYS DISCONNECT SAW BEFORE MAKING ANY ADJUSTMENTS! Place the work

with its "good” side—the one on which appearance is most important—down.

The saw cuts upward, so any splintering will be on the work face that is up when

you saw it.

Support the work so that the cut will be on your right. Place the wider portion of

the saw shoe on that part of the work piece which is solidly supported, not on the

section that will fall off when the cut is made. As examples. Figure 9 illustrates

the RIGHT way to cut off the end of a board, and Figure 10 the WRONG way. If

the work is short or small, clamp it down. Don't try to hold short pieces by hand!

FIG. 9 -RIGHT

FIG. 10 - WRONG

Draw the required guide lines. Then rest the front of the saw shoe on the work

with the guide edge lined up with the drawn guide line. Before starting the motor,

push the blade lightly against the edge of the work and then back off about

Now, start the motor, and when the blade gains full speed, push the saw forward

and begin sawing. As you begin cutting, the lower blade guard will automatically

begin to telescope into the upper blade guard. This telescoping action will continue

as you advance the saw until it reaches the position in Figure 9

Push the saw forward at a speed which allows the blade to cut without laboring.

Hardness and toughness can vary even in the same piece of material, and a

knotty or damp section can put a heavy load on the saw. When this happens, push

the saw more slowly, but hard enough to keep it working without much decrease

in speed. Forcing it beyond this makes for rough cuts, inaccuracy and overheating

of the motor.

Should your cut begin to go off the line, don’t try to force the saw back on. Re

lease trigger and allow blade to come to a complete stop. Then you can withdraw

the saw, sight anew, and start a new cut a trifle inside the wrong one. In any

event, withdraw the saw if you must shift the cut. Forcing a correction inside the

cut can stall the saw and perhaps spoil the work. IF SAW STALLS, RELEASE THE

TRIGGER, BACK THE SAW UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN

THE CUT BEFORE RESTARTING.

As you finish a cut, release the trigger and allow the blade to stop before lifting

the saw from the work. As you lift the saw the spring-tensioned telescoping guard

will automatically close under the saw. Remember the blade is exposed until this

occurs; never reach under the work for any reason whatsoever. When you have to

retract the telescoping guard manually (as is necessary for starting pocket cuts)

always use the retracting lever.