Black & decker circular saw blades – Black & Decker cat 3027-90 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BLACK & DECKER CIRCULAR SAW BLADES

A dull blade will cause slow, inefficient cutting and will overload the saw motor. It is a

good practice to keep extra blades on hand so that sharp blades are available while the dull

ones are being sharpened (See "SAWS—SHARPENING" in Yellow Pages). In fact, many lower

priced blades can be replaced with new ones at very little cost over the sharpening price. USE

ONLY

7 1

/

4

", 7%" or 7" BLADES, WITH

%"

ARBOR HOLE, ON YOUR SAW.

Hardened gum on the blade will slow down the cutting. This gum can best be removed with

trichlorethylene, kerosene or turpentine. Remove blade before cleaning to prevent solvent from

damaging plastic parts of saw.

Black & Decker manufactures a complete line of saw blades and the following types are

available.

Standard; Outstanding value for the price. These blades are also available in bulk quantities.

Ask for quantity prices. (When sold in bulk, "-01" is added to catalog number).

Premium: Industrial chrome plating gives twice the cutting life of unplated blades.

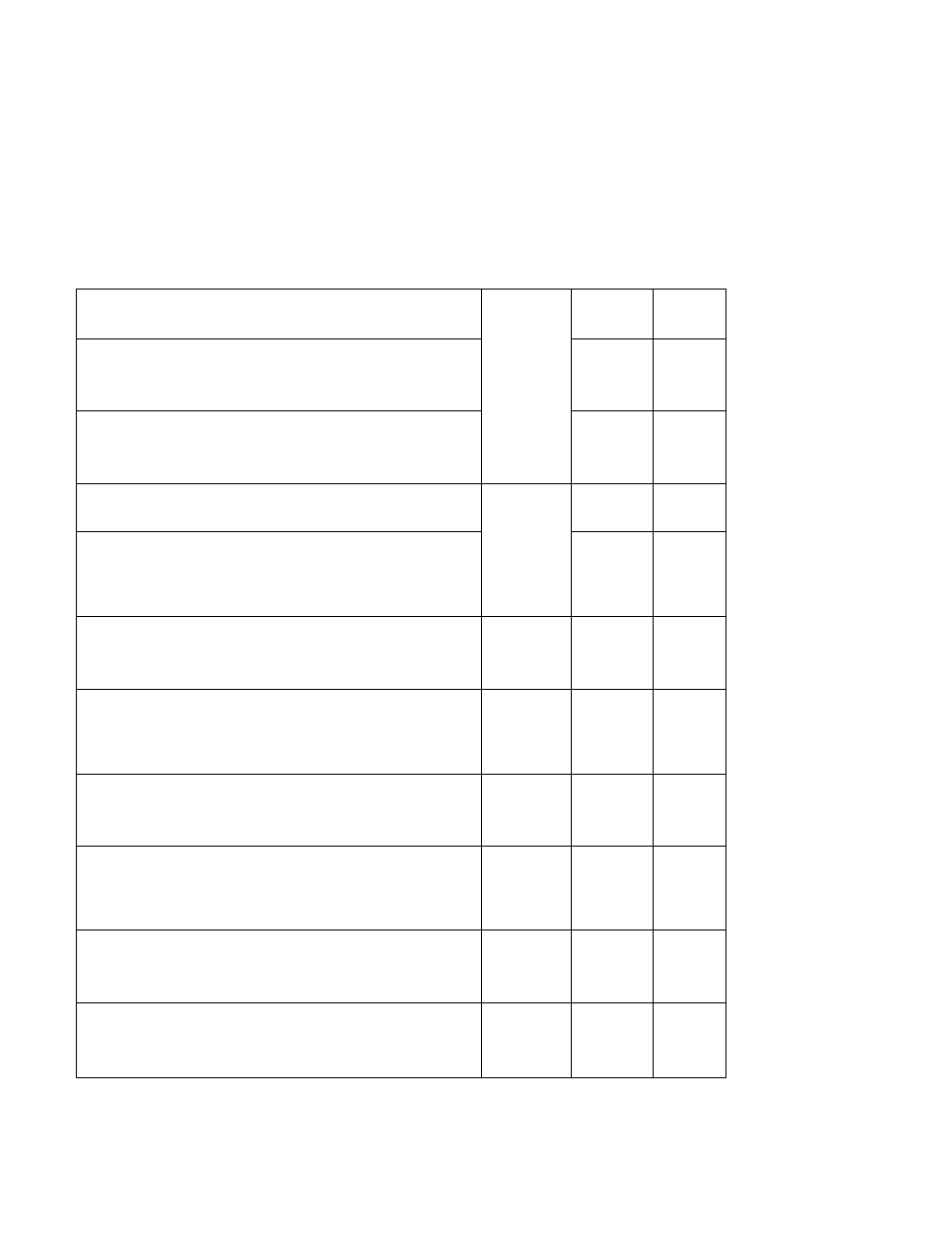

TYPE OF BLADE

TOOTH

SHAPE

>

COMBINATION

Chisel

tooth

configuration

means

this

blade is the fastest cutting blade in our line. Specifically

designed for general-purpose ripping and cross-cutting

where the finish of the cut is not critical.

FRAMING/RIP

An

all-purpose

blade

for

smooth,

fast

cutting in any direction. Rips, crosscuts, miters, etc.

Gives especially fast, smooth finishes when cutting with

the grain of both soft and hard woods.

METAL CUTTING Teeth shaped and set specifically for

cutting aluminum, copper, lead and other soft metals.

HOLLOW

GROUND

PLANER

Specially

ground

for

satin-smooth finish cuts (cross-cuts, rips and miters) In

all solid woods. A professional quality blade for use In

cabinet

work,

furniture,

etc.

Specifically

designed

to

make extremely smooth cuts in wood.

CARBIDE TIPPED (8 tooth) Specially designed for cut

ting tough-to-cut materials such as: Transite, Cemesto

board, asbestos, Formica and Masonite. Will also cut

wood where speed and finish are not critical.

CARBIDE TIPPED (20 tooth) Chisel tooth combination

blade for fast general-purpose cutting in all types of

woods. Tips are of tungsten carbide material which out

lasts regular steel blades up to 10 to 1. Teeth are accu

rately set for ease of cutting.

FLOORING For use where nails or other metal objects

may be encountered, such as cutting reclaimed lumber,

flooring, opening crates. Allows crosscuts as well as

miters.

HOLLOW

GROUND

PLYWOOD

Special

taper

grinding

on the sides of this thin-rim blade gives an absolutely

smooth cut in plywood, veneers and laminates, etc. Can

be used in crosscutting and mitering for a professional

finish on ail types of cabinet work.

STEEL CUTTING FRICTION Designed for cutting cor-

rugated or sheet roofing, black Iron, furnace pipe or

thin bar stock. Cuts faster with less filings than abra

sive blades. Cuts by friction action.

rry

CROSS-CUT Specifically designed for smooth, fast cut

ting cross the grain of both hard and soft woods where

finish is an Important factor. May also be used for rip

and crosscuts on extremely hard woods.

ABRASIVE BLADES (Fiberglass Reinforced)

Aluminum Oxide cuts ferrous

metals and hardened non-ferrous

metals.

Silicon Carbide cuts masonry

materials and soft non-ferrous

metals.

11