Bevel angle adjustment, Guide edges, Figure 5 – Black & Decker cat 3027-90 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

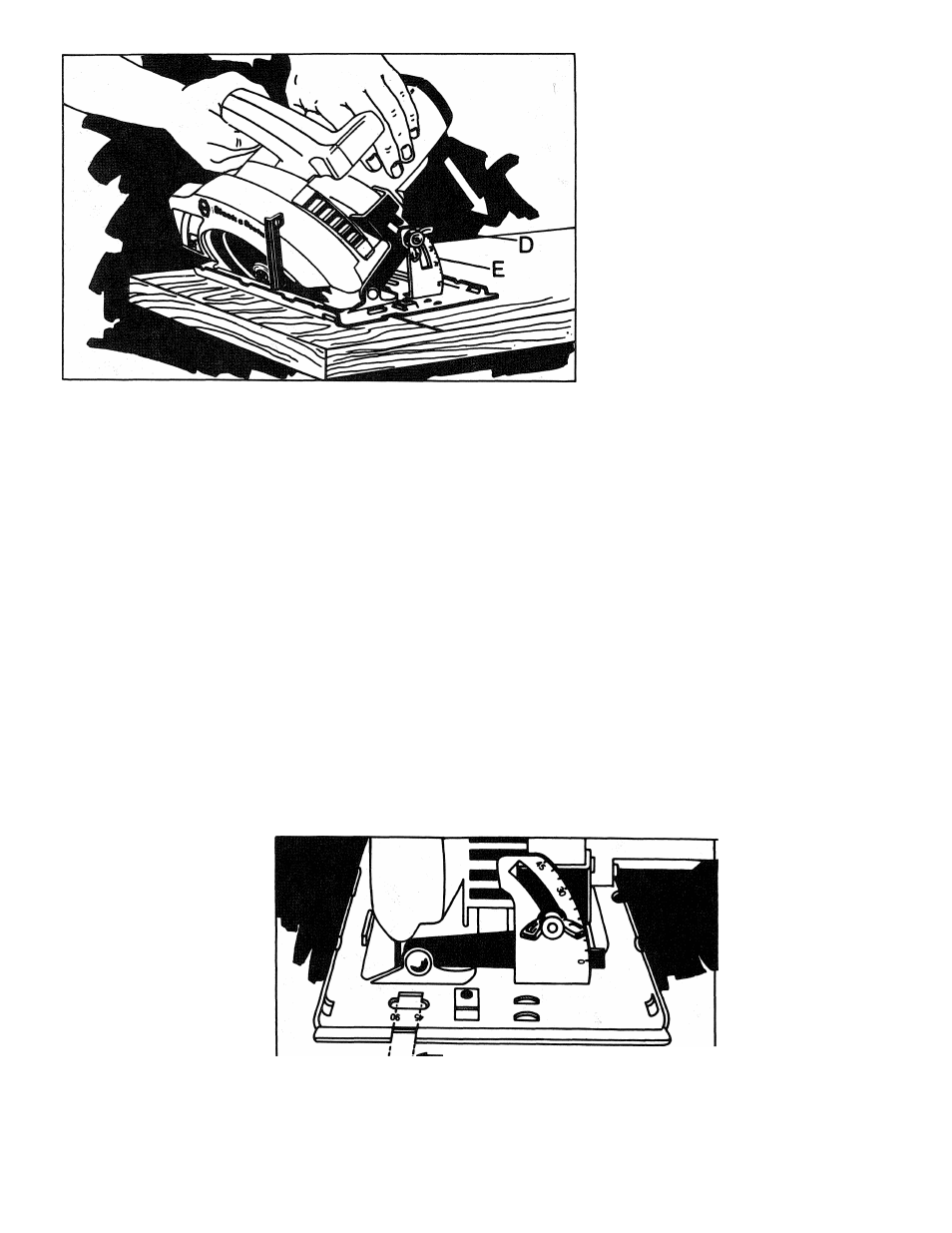

FIGURE 4

BEVEL ANGLE ADJUSTMENT

DISCONNECT THE SAW FROM THE POWER SUPPLY BY PULLING THE PLUG,

BEFORE MAKING THIS, OR ANY OTHER ADJUSTMENT! On the front of the saw

is a bevel angle adjustment device (Figure 4) consisting of calibrated quadrant

“E” and a knob “D”. To set the saw for a bevel cut, loosen knob and tilt shoe

to angle desired. Retighten knob firmly.

CAUTION: When making bevel cuts, place one hand on the motor housing as

shown in Figure 4. Exert only enough pressure in the direction of the arrow to

keep the saw shoe flat on the work. This will insure an accurate bevel cutting

angle and help prevent the blade from binding in the cut.

GUIDE ALONG PENCILLED GUTTING LINE

SO KERF FALLS IN WASTE STOCK —

GUIDE EDGES

Guide along the penciled cut

ting line so that the kerf falls

into the waste or surplus

material—See Figure 5.

DESIRED

- LENGTH -

OF STOCK

WASTE

OR

SURPLUS

STOCK

FIGURE 5

-KERF

An Adjustable Guide on

the front of the saw

shoe

has

two

guide

edges (Figure 6)—one

for vertical cutting, and

one for 45‘’bevel cut

ting. These edges en

able you to guide the

saw along penciled lines,

and the edges line up

with the left (inner) side

of the saw blade. This

makes the slot or "kerf"

cut by the moving blade

fall to the right of the

guide mark.

45* BEVEL CUT 1 GUIDE

0* VERTICAL CUTJ EDGES

FIGURE 6