Bryant 342S User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

S E P / 0 9 / 2 0 0 8 / T D E 0 3 : 3 3 P M UTC TECH PUB

P A X N o , 3 1 7 2 4 0 5 6 6 2

Check all connections in gas piping for leaks. Use soap-

and-water solution.

VIL SERVICE AND MAINTENANCE

1.

Pilot Orifice - is located in bottom fitting of pilot and is

K

readily accessible for inspection and cleaning.

3. Main Burner Orifices - Orifice is readily unscrewed

from manifold after burner is removed,

3. Removing Main Burners - Lift rear of burner and push

it away from manifold enough to disengage orifice spud

from mixer shield. Then pull down and out of heater.

End of burner away from manifold seats in slotted

burner support. It is necessary to lift burner out of this

slot before attempting to push burner back. See Figure

12

.

NOTE: Disconnect the pilot tubing and wires to remove the

burner that holds the pilot. However, it is not necessary to

remove the pilot itself from the burner.

4. Cleaning - Heat exchanger tubes should be inspected

at regular intervals and cleaned when necessary.

a. Shut off gas and electricity. Heater should be cool.

b. Loosen two knurled-head screws to release rear

access door. Door will hang down freely.

c. Disconnect pilot tube and wireg.

d. Remove main burners and pilot.

e. Use stiff brush to scrub heat exchanger tubes.

Remove all loose scale and any soot that may have

collected.

f. Replace burners and pilot. Reconnect pilot tube

and wires.

g. Unit is now ready for relighting.

5. Oiling - Oil fan motor (s) yearly, or more often, with

enough drops of SAE No. 20 nondetergent oil to

overflow oil cup; or every 2 years, or more often, with

Anderol L-465* obtainable in tubes from your dealer.

(Bryant P/N 7O291D01). See FTB143.

*Lehigh Chemical Company

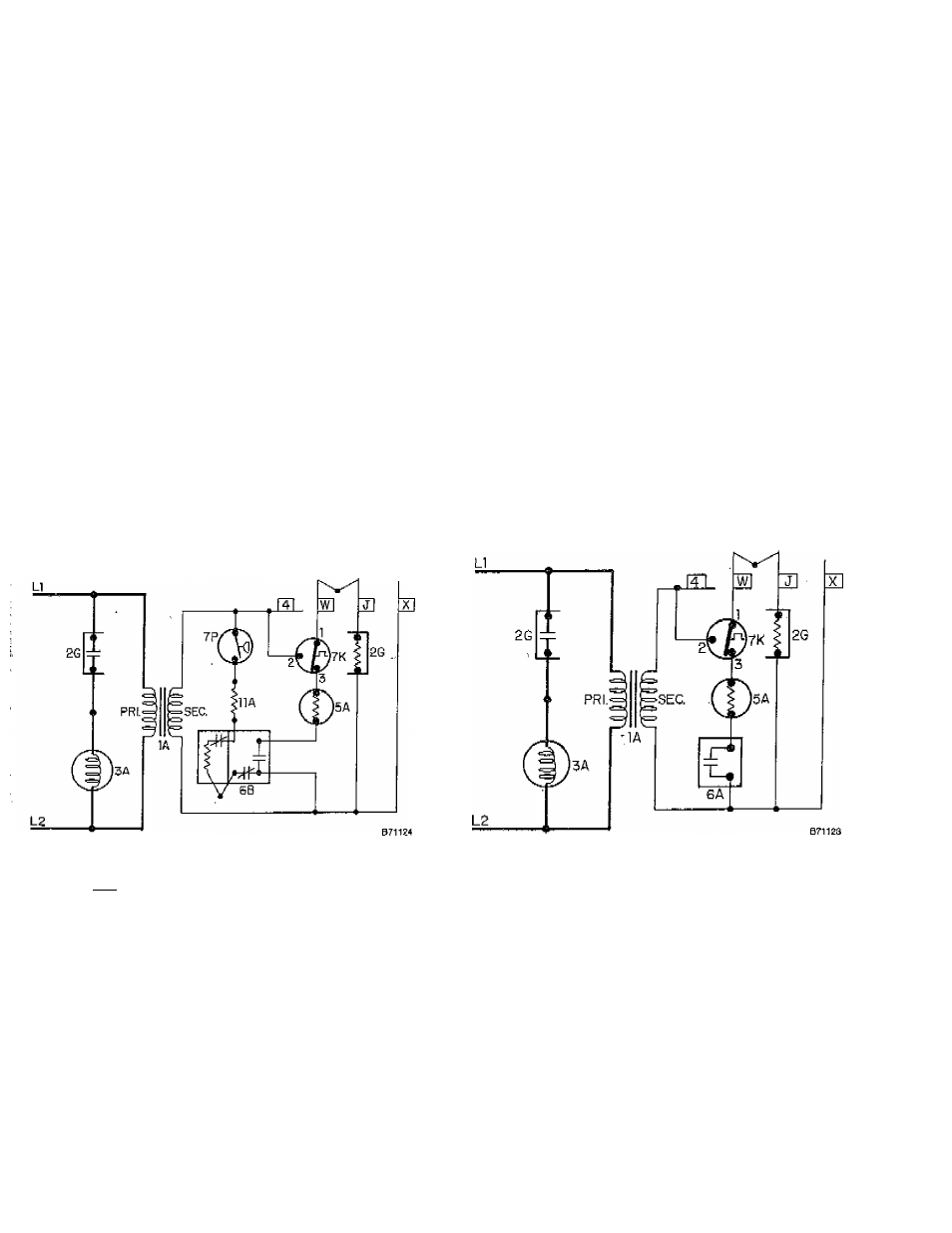

SIZES 30 THRU 150 UNIT HEATER WIRING DIAGRAMS

Figure 3^With 733 Pilot ihstaííed

:: :

4—УУ1Ш

FIIQÍ installed

LEGEND

1A

Transformer

6B

Pilot with Auto.

SG

Pan Relay—N.O,

Ignition Coil

ЗА

Fan Motor

7K

Temp Limit Control—

3A1

Fan Motor

SPOT—N.C.

3A2

Fan Motor

7P

Pressure Switch^—

3C

Fan Motor

SPST—N.O.

5A

Automatic Gas Valve

11A

Resistor

0A

Pilot Switch—No.O.

If wires are replaced, use 18 AWG

(None on Propane)

150“

C.,

3/64-inch thick insulation.

—

4

-