Bolens 140-830A User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Linkage—Once a season lubricate all the pivot

points on the clutch, brake and lift linkage with

SAE 30 engine oil.

Wheel

Bearings—The

front

wheel

bearings

and

king pin bearings have Oilon PV 80 bearings that

require no lubrication.

Ball Joints—The ball joints and drag link ends are

permanently lubricated.

Fuel Shut-Off Valve and Filter

The valve and filter is located on the bottom of the

gasoline tank located at the extreme rear of the

tractor.

Turn the valve knob in to shut off the fuel flow.

Turn the valve knob out to operate the tractor. (See

figure 17.)

The entire valve can be pulled out to clean the

filter. When reassembling, place the rubber grom

met into the gasoline tank first, then push the

valve all the way in.

\

WARNING {

Only use factory approved parts if

repairs are needed on the gasoline

tank, grommet, valve or gasoline

line.

Grommet

Filter

I

h

Valve

FIGURE 17.

Installation of Tire to Rim

\

WARNING {

The following procedure must be

followed when removing or instal

ling a tire to the rim.

1. Lubricate the tire beads and rim flanges.

2. Do not exceed 30 p.s.i. when seating beads.

3. Adjust to recommended pressure after beads

are sealed.

Rear Wheel Tract Adjustment

The distance between the rear wheels can be

changed from wide to narrow by removing the rear

wheels one at a time and reversing them on the

hub.

With the rear wheels in the narrow position, the

outside of the rear wheels is even with the outside

of the front wheels.

With the rear wheels in the wide position, the in

side of the rear wheels is even with the inside of

the front wheels.

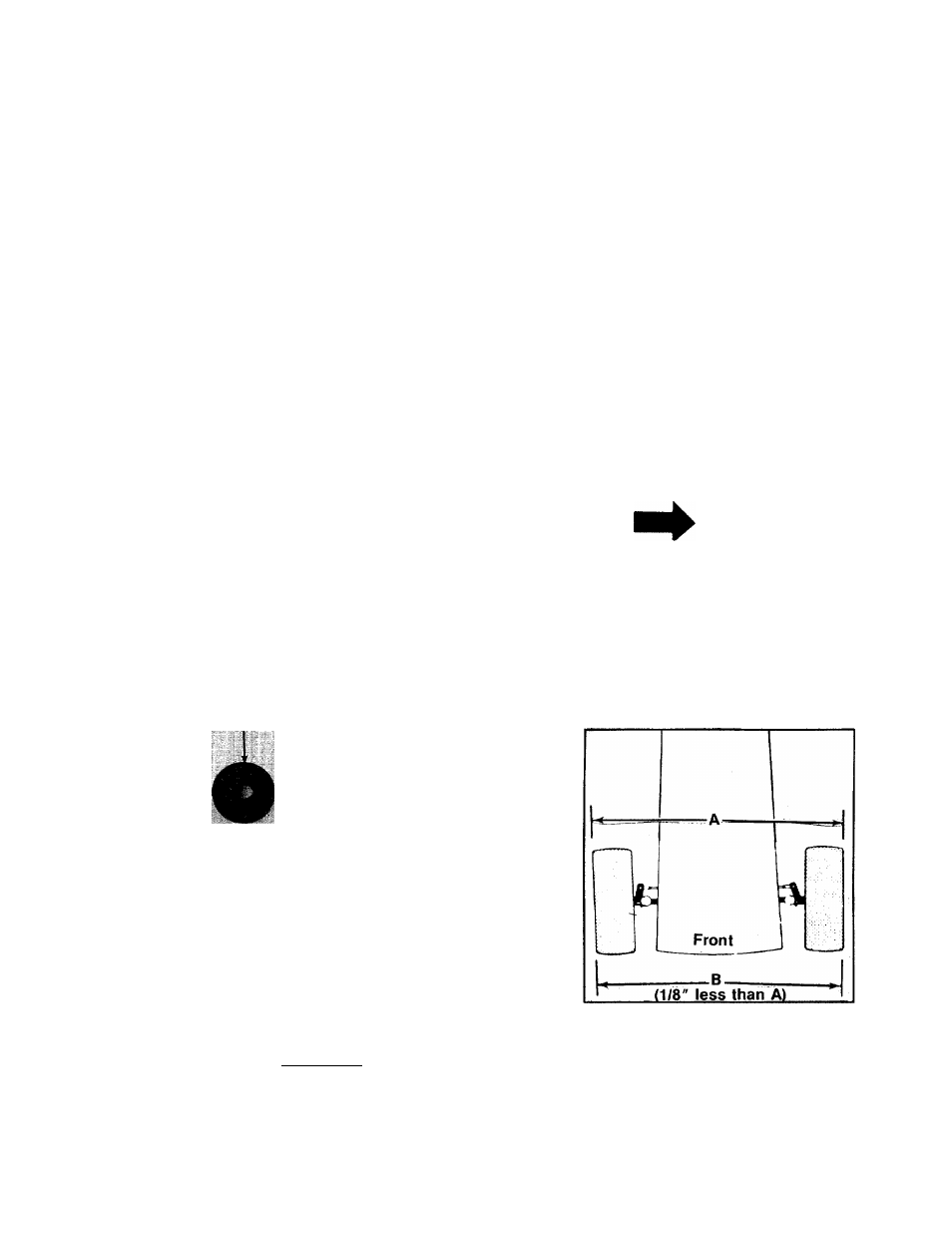

Wheel Alignment

The front wheels should toe-in approximately 1/8".

Measure the distances A and B on the front

wheels, (See figure 18.)

NOTE

Dimension B should be approx

imately

1/8

inch less than dimension

A.

To adjust the toe-in, loosen the hex jam nut,

remove the elastic locknut, lift the tie rod end out

of the hole in the steering arm and screw the tie

rod end in or out as necessary. (See figure 18.)

Reassemble the tie rod end after the correct align

ment is made.

FIGURE 18.

Drag Link

If the drag link or ball joints are changed, the new

assembly must be adjusted to the exact same

length as the original. If adjusted wrong it will

allow the tractor to turn sharper one direction than

the other.

13