Align holes, Lubrication – Bolens 840 thru 849 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

8. Tighten hex jam nut (A) against the ball joint.

9. Reattach the ball joint to the steering arm with hex

nut (B). Finger tighten only at this time.

10. Turn the steering wheel fully to the left and the right

to make sure that the drag link does not touch any

part of the tractor frame. If the drag link does

touch, start at step 1 and redo the adjustment.

11. Tighten hex nut (B).

12. Remove the nail used to align the steering gear.

Steering Place Nail Drag Link

Brace

Av ^ ^^CjHex Jam Nut (A)

Ball Joint

Lock

Washer (C)

Paper

Align

Holes

Steering Gear

FIGURE 19.

Hex Nut (B)

Steering Arm

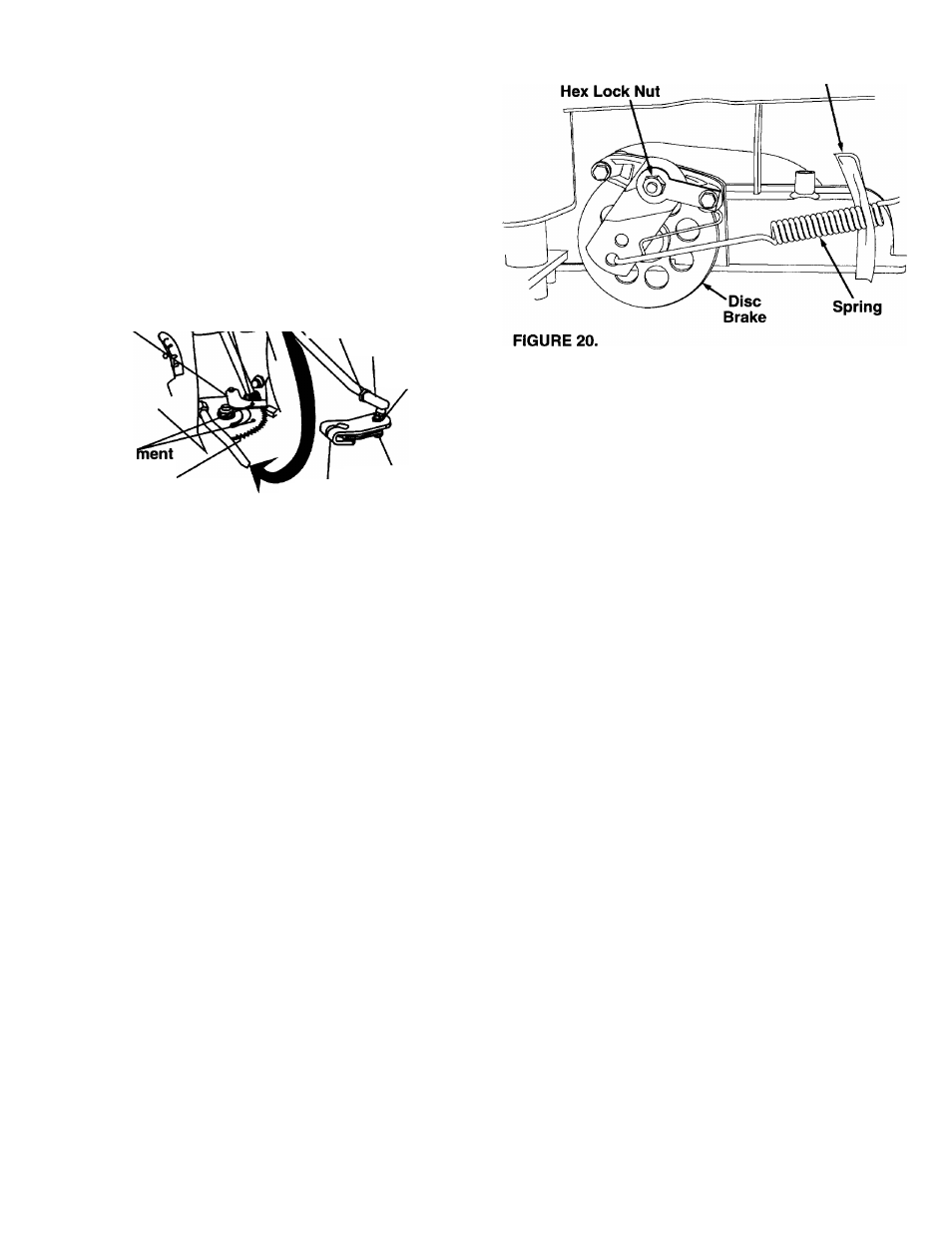

BRAKE ADJUSTMENT

(See figure

20

)

The brake is located on the right side of the transaxle.

During normal operation of this machine, the brake is

subject to wear and will require periodic examination

and adjustment. To see if brake needs adjusting pro

ceed as follows.

A

WARNING: Do not adjust the brake while

the engine is running. Be sure to block

the wheels of the tractor before making

the brake adjustment.

1. Set the parking brake by depressing the clutch-

brake pedal and pulling up the parking brake

knob.

2. Working on the right side of the tractor, try insert

ing a piece of paper through the coils of the brake

spring. See figure 20.

3. If the paper can be inserted through the coils of

the brake spring, the brake is properly adjusted.

4. If the paper cannot be inserted, tighten the hex

lock nut until the paper can be inserted through

the coils.

5. Release the parking brake and place the tractor in

neutral. Depress the clutch-brake pedal and try

rolling the tractor. The tractor should not move. If

the tractor moves, repeat the above steps until

proper brake adjustment is achieved.

CARBURETOR ADJUSTMENTS

A

WARNING: If any adjustments are made to

the engine while the engine is running

(e.g. carburetor), disengage all clutches

and blades. Keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

Minor carburetor adjustments may be required to

compensate for differences in fuel, temperature,

altitude and load. Refer to separate engine manual

for carburetor adjustment information.

NOTE: A dirty air cleaner will cause an engine to run

rough. Be certain air cleaner Is clean and attached to

the carburetor before adjusting carburetor.

LUBRICATION

A

WARNING: Always stop engine and dis

connect spark plug wire(s) before clean

ing, lubricating or doing any kind of work

on lawn tractor.

STEERING GEARS

Lubricate teeth of steering gears with automotive

multi-purpose grease after every 25 hours of operation

or once a season. Refer to figure 19.

STEERING SHAFT

Lubricate steering shaft at least once a season with

light oil.

TRANSAXLE

The transaxle is lubricated and sealed at the factory

and does not require checking. If disassembled for any

reason, lubricate with 32 oz. of Shell Darina grease,

part number 737-0148 (16 oz. tube).

LINKAGE

Once a season lubricate all the pivot points on the

clutch, brake and lift linkage with SAE 30 engine oil.

17