Bryant GAS-FIRED 454 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2. The gas supply pipe enters the unit through

a knockout located in the rear of the unit near

the left side. This unit requires one nipple

that is threaded into the 1 /2 -inch combination

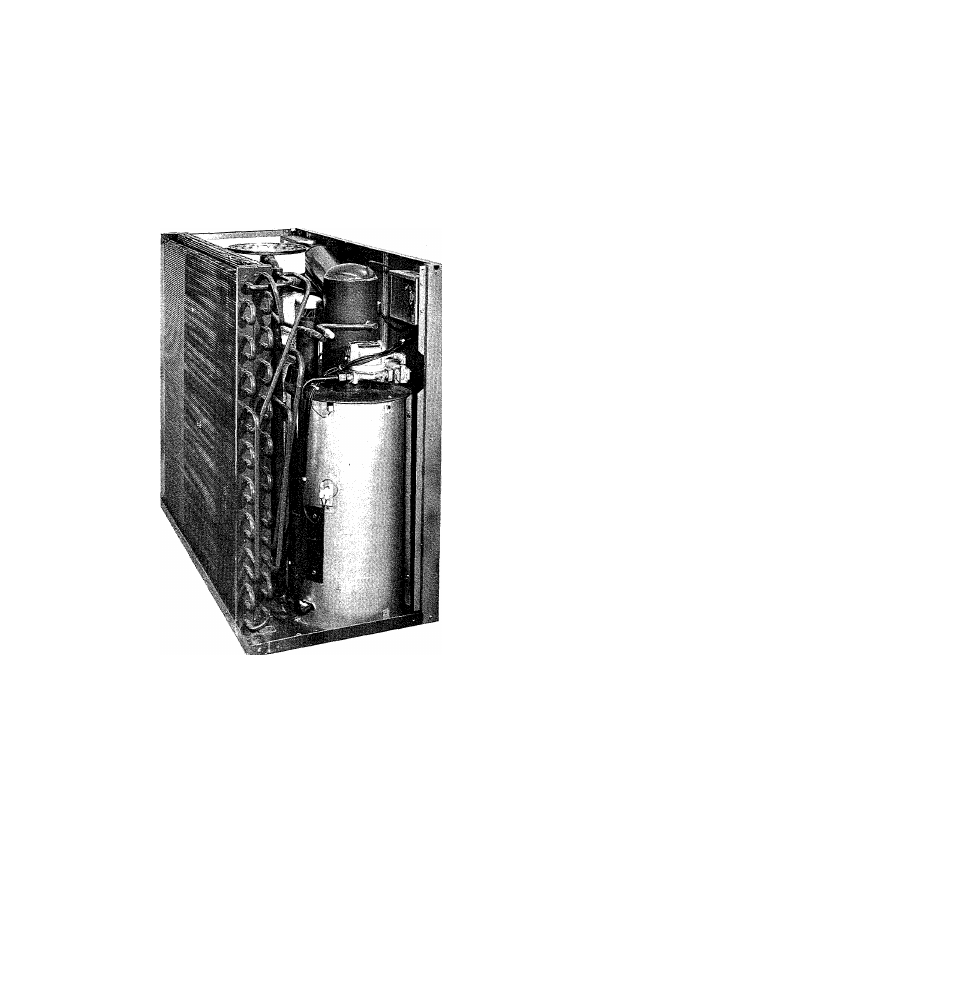

regulator-shutoff valve, see Figure 3 .

3. A wrench-type shutoff valve should be in

stalled in the gas line within sight of, and

convenient to the unit.

Figure 3 • Gas Connections

4. Joint compound (pipe dope) which is re

sistant to the action of liquefied petroleum

gases should be applied sparingly and only to

the male threads of the joints .

5. Install a drip leg trap in the gas supply

riser leading to the unit. After gas pipe con

nections have been made, purge the lines, as

described below, and check for leakage. Use

a soap and water or other recommended

solution.

6. Never use matches, candles, flame or

other source of ignition to check for leaks.

Pilot

Light the pilot, using the procedure outlined

on the unit rating plate. However, when

lighting the pilot for the first time, perform (

the following additional steps;

1. If the supply line was not purged prior to

connecting the unit, it will be full of air.

Since it would take a long time to vent this

air through the small pilot port, it is recom -

mended that the pilot supply line be discon

nected at the pilot shutoff valve and the supply

line be allowed to purge until the odor of gas

is detected. Never purge gas lines into the

combustion chamber. Immediately upon de

tection of gas odor, reconnect the pilot supply

tube. Allow 5 minutes to elapse and light the

pilot in accordance with the instructions on

the lighting plate.

2. The pilot flame should be soft blue in

color.

a. For natural gas this flame should be of

sufficient length to provide good impinge

ment on the unimetal of the Bryant pilot.

The flame should extend upward and above

main burner ports .

3. If the pilot flame does not have the ap

pearance described above, it may be adjusted

at the manual pilot shutoff valve.

a . The valve is equipped with an adjustable

screw. Turn the handle to the full open

position, and remove the screw cap to ex

pose the adjustable screw. Turn adjusting

screw until flame has the desired appear

ance .

b. Replace screw cap.

V.

CHARGING THE SYSTEM WITH WATER

Coûtions:

1. Do not run the pump dry.

2. Do not operate the pump when the chiller

or chilled water lines are frozen. Freezing

temperatures, however, will not damage the

pump.

3 . The gas valve on the unit should be closed

when operating the unit during the following

procedures.

35/454

- 6 -