Bryant GAS-FIRED 454 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Materials

1 . Chilled Water Piping

a. Use Bryant quick connect plastic hose.

b. Polyethylene pipe - satisfactory substi

tute; use medium density flexible pipe

whose wall thickness approximates

Schedule 40 pipe (Commercial Standard

CS 255-63). Pipe must be made from

virgin material. Do not use pipe manu

factured from re-claimed material.

c . Copper - satisfactory substitute .

d. Brass - satisfactory substitute.

2. Fittings

a. Galvanized - use when possible.

b. Brass - satisfactory substitute .

Pipe Length and Diameter

Table I shows the maximum length of pipe of

different diameters that can be used between

the pump discharge and the coil inlet and still

maintain minimum allowable (design) water

flow rate.

1. Multiply table values by two to obtain the

total length of pipe from chiller to coU and

return.

2. Length is measured along the pipe path

and therefore includes vertical distance be

tween the water coil and the chiller.

3. Lengths shown in Table I are based on

using a total of eight well head fittings in the

entire water line (chiller to coil and return).

Lengths are predicated on the use of a Bryant

matching water coil. For greater distances

use larger size pipe.

4. For calculating chilled water pipe size for

coils not listed use friction loss method with

allowance for coil pressure loss. Refer to

coil instructions for pressure loss at design

water flow rate. Refer to Table II showing

available head with standard pump drive. For

additional pump head consult your Bryant

Distributor.

Insulation

1. Insulate both supply and return lines .

2. Material should be of good quality and be

covered with a good vapor barrier. Armaflex

or equivalent is recommended. Use 1/2-inch

wall thickness .(Plastic hose is pre-insulated.)

36/454

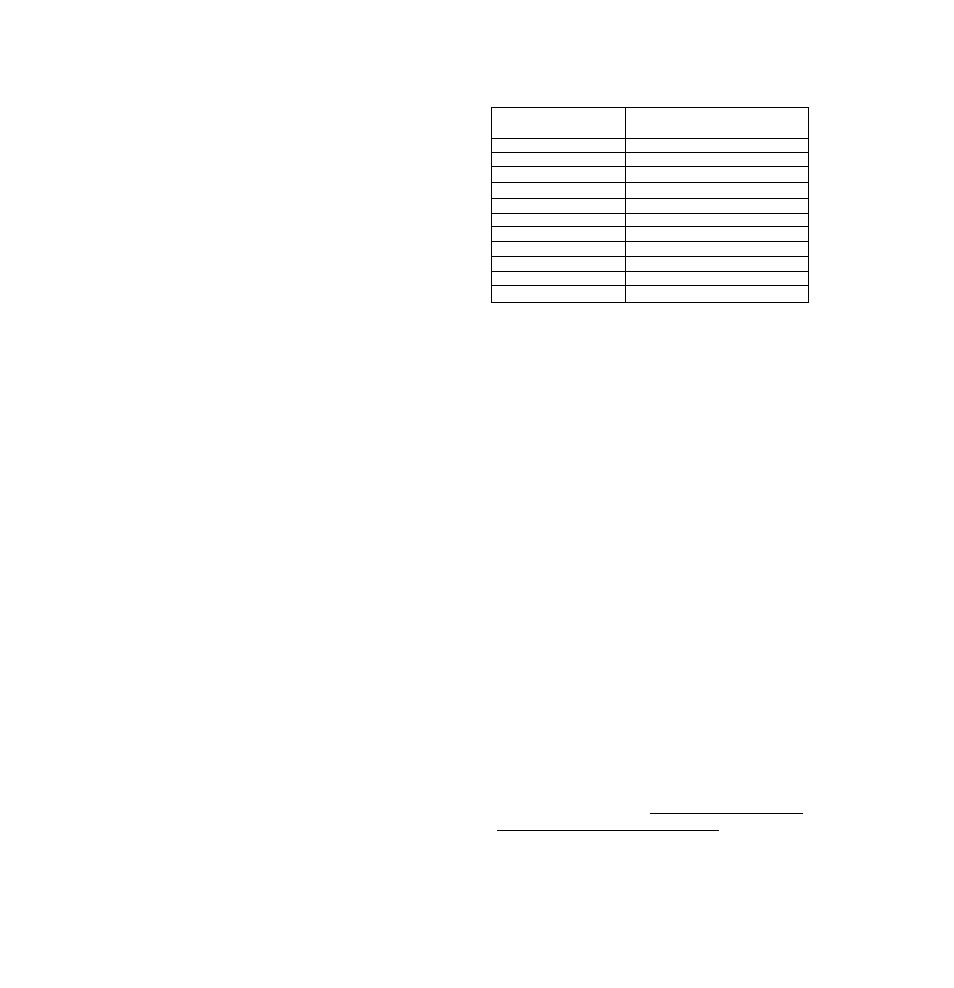

WATER FLOW RATE

AT VARIOUS EXTERNAL PRESSURES

Table II - Model 36-454

Water Flow Rate

Pressure External to Unit

GPM

Ft Water Std RPM

2.0

25.9

3.0

25.5

'4.0

25.0

5.0

24.5

6.0

23.8

7.0

23.0

7.5

22.5

8.0

22.0

9.0

21.0

10.0

19.7

11.0

18.6

Height of Coil above Unit

For the Model 36-454 the maximum vertical

distance from chiller to top of coil is 21 feet.

For greater heights an adjustable water pump

pulley kit is available, Part No. 65070D01.

Water Coil Connections

1. If the cooling coil is used in connection

with a heating unit and the heating unit is not

approved for installation downstream from

the cooling coil, install the cooling coil in

parallel with or downstream from the heating

unit. This will avoid condensation in the heat

ing unit. If the coil and heating unit are in

stalled in parallel, the dampers or other

means used to control flow of air should be

adequate to prevent chilled air from entering

the heating unit; if manually operated, the

dampers shall be equipped with some means

to prevent operation of either unit uiiless the

dampers are in full heat or full cool position.

2. If the coil is located in a warm air stream,

do not connect polyethylene pipe directly to

the coil. Connect a minimum of 24 inches of

copper or galvanized pipe to both the coil in

let and outlet; then connect the polyethylene

pipe to these nipples . Note: not required when

using Bryant quick connect plastic hose.

3. On installations where the water in the

outside piping freezes and the coil is in a

heated air stream, precautions must be taken

to provide for water expansion. The connect

ing polyethylene pipe acts as an expansion

vessel if there is sufficient footage in the

-

4

-