Introduction to troubleshooting – Generac Power Systems IM Series User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INTRODUCTION TO TROUBLESHOOTING

Introduction

A typical RV generator set does not have a large number

of parts. However, the parts are expensive. For that

reason, a parts replacement method of troubleshooting is

not cost effective. A basic understanding of generators is

essential to good troubleshooting, i.e., why they behave

or don’t behave as they should. This section will introduce

the technician to some of the fundamentals of

troubleshooting.

DANGER!: Recreational vehicle generators produce

extremely high and dangerous voltages. Use ex

treme care when working on or around the gener

ator. Contact with live wires and terminals will cause

extremely hazardous and possibly lethal electrical

shock. Only personnel who have been thoroughly

trained In the maintenance of RV generators should

attempt to troubleshoot, test, repair or service a gen

erator.

Tools and Test Equipment

The generator service technician should have a well

stocked tool box having a good selection of common hand

tools. Such a tool box should contain wrenches in both

metric and english sizes. Also recommended is a good

nut driver set.

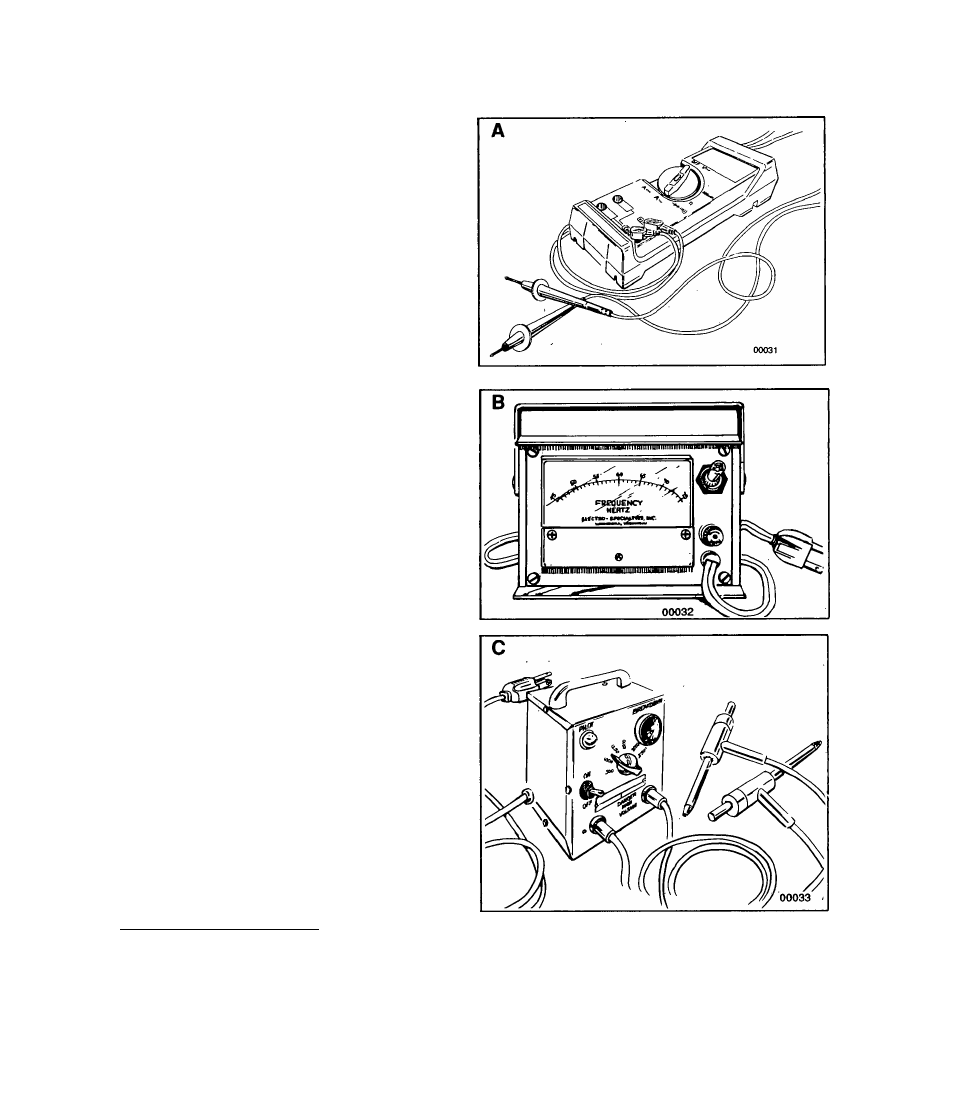

A

Volt-Ohm-Milliammeter:-An accurate volt-ohm-mil-

liammeter (VOM) is essential for the troubleshooting and

testing of generators. Simply having a VOM is not

enough. The technician must understand electricity, must

be familiar with electrical circuits, must be able to read

wiring diagrams/electrical schematics, and must know

how tio use the VOM.

B

Frequency Meter:- This test device permits the gen

erator’s a-c ou^ut frequency, in HERTZ or CYCLES PER

SECOND, to be read. Measurement of frequency is re

quired for precise adjustment of engine-generator speed.

Also see ROTOR ROTATIONAL SPEED.

C

Insulation Resistance Tester:- Also called a "Hl-

POT", this device permits generator Stator and Rotor

winding insulation to be tested for breakdown. Use the

Hi-Pot tester to test resistance between parallel stator

windings, between isolated windings, and the resistance

of all windings to ground. See also EFFECTS OF DIRT

AND MOISTURE ON GENERATORS.

NOTE: An electrical LOAD BANK Is also recom

mended for generator testing and adjustment. The

Load Bank permits a known electrical load to be ap

plied to the generator, for the purpose of testing/ad-

justlng unit operation under load.__________________

Rotor Rotational Speed

The generator’s revolving field on Series NP45G, NP55G

and NP65G generators is a 2-pole type, having a single

north and a single south magnetic pole. The Rotor is en

gine driven through a belt and pulley arrangenrient. Such

a 2-pole Rotor must be operated at 3600 rpm to supply

an a-c frequency output of 60 Hz. The belt and pulley ar

rangement pro>4des a speed reduction, so that engine

speed can be reduced while driving the Rotor at its re

quired operating speed. The following formulae apply