Troubleshooting guidelines – Generac Power Systems IM Series User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TROUBLESHOOTING GUIDELINES

Problem No. 1- Engine Won’t Crank

step 1- Check 15 amp Fuse F1

Test Procedure: Remove Fuse FI from generator panel

and Inspect fuse element. If necessary, use a Volt-Ohm-

Mllllammeter (VOM) to check fuse for continuity.

Test Results:-

A. Fuse FI checks GOOD: Go to Step 2

B. Fuse FI Is open: Replace Fuse FI. If engine cranks

normally STOP.

Step 2- Check Battery

Test Procedure:- Perform the following checks/tests on

the generator battery:

1. Inspect battery terminals (posts) and cables. Cable

clamps and connections must be clean and tight. Glean

and/or tighten cable clamps and connections as neces

sary. Replace any defective cables.

2. Use an automotive type battery hydrometer to test bat

tery STATE OF CHARGE. Follow the hydrometer

manufacturer’s instructions carefully. Write down the

specific gravity of the electrolyte fluid in each battery cell.

Write down the specific gravity reading of each cell as the

reading is taken. Return the electrolyte fluid to the cell

from which it was removed. If the hydrometer used does

not have a percentage of charge scale, compare the read

ings obtained with the following:

SPECIFIC GRAVITY PERCENT OF CHARGE

1.260

1.230

1.200

1.170

100

%

75%

50%

25%

If necessary, use an automotive type battery charger to

recharge the battery to a 100% state of charge.

DANGER!: Storage batteries give off EXPLOSIVE

hydrogen gas while charging. Completely remove

the battery from the vehicle before attempting to

recharge It. Charge the battery only In a well venti

lated space where explosive gases cannot accumu

late and present the danger of explosion. Do not per

mit smoking, open flame or sparks in the vicinity

while charging a battery._________________________

3. If the difference in specific gravity between the highest

and lowest reading cell is 0.050 (50 points) or greater, the

battery is nearing the end of its usefui life and should be

replaced. However, if the lowest reading cell has a

specific gravity of less than 1.200, recharge the battery

and then repeat the specific gravity test. If, after charg

ing, the difference between the highest and lowest read

ing cell is still 0.050 (50 points), replace the battery.

Test Results:-

A. Normal engine cranking occurs: STOP tests

B. Battery checks GOOD, no cranking; Go to Step 3.

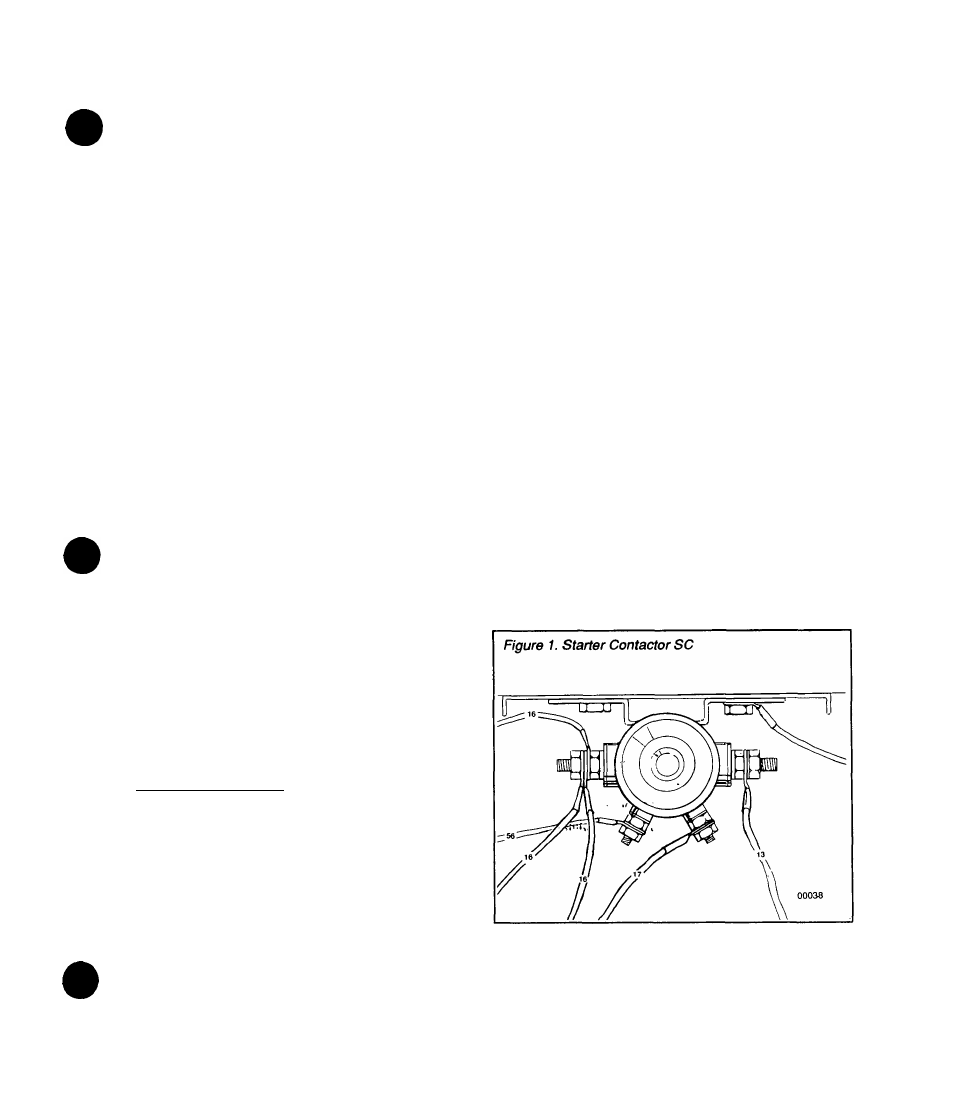

Step 3- Check Starter Contactor SC

Test Procedure:- Starter Contactor operation may be

tested as follows:

1. See Figure 1. Connect the positive (+) test lead of a d-

c voltmeter to the Wire 56 terminal of the Starter Contac

tor. Connect the meter negative (-) test lead to a clean

frame ground. The voltmeter should indicate battery vent

age (12 volts d-c).

Test Results:

A. Battery voltage NOT indicated: Go to Step 6

B. Battery voltage was indicated: Continue test

2. Connect the positive (+) test lead of a d-c voltmeter to

the Wire 16 terminal stud of the Starter Contactor; con

nect negative (-) test lead to a dean frame ground. Zero

volts should be indicated.

3. With d-c voltmeter still connected to the Wire 16 ter

minal stud and frame ground, disconnect Wire 17 from its

terminal stud on Starter Contactor. Connect a jumper wire

from the Wire 17 terminal stud (on Starter Contactor) to

a clean frame ground. The d-c voltmeter should indicate

battery voltage and engine should crank.

Test Results:

A. Battery voltage GOOD and engine cranks, but will not

crank with Start/Stop Switch: Go to Step 5

B. Battery voltage GOOD, engine does NOT crank: Go

to Step 4

C. Zero battery voltage with jumper wire connected and

engine does not crank; Replace Starter Contactor SC.

Step 4- Check Starter Motor SM

Test Procedure:- Connect a jumper cable to the large

battery cable terminal stud (Wire 13) of the Starter Con

13