Adjustments – Generac Power Systems IM Series User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ADJUSTMENTS

General

This section is inciuded with other a-c generator informa

tion, because the covered information is so important to

proper generator operation and correct a-c output. The

engine governor adjustment may belong in the ENGINE

SERVICE MANUAL. However, that adjustment is so

important to correct a-c output frequency and voltage that

it is included here.

Adjustments included in this section include thefollowing:

1. Engine governor adjustment.

2. Voltage Regulator adjustment

3. Automatic Choke adjustment.

NOTE: An optional LP gas (propane) fuel system Is

available for use with the NP series generators.

Instructions for the installation and adjustment of

the LP gas conversion kit are Included with the kit.

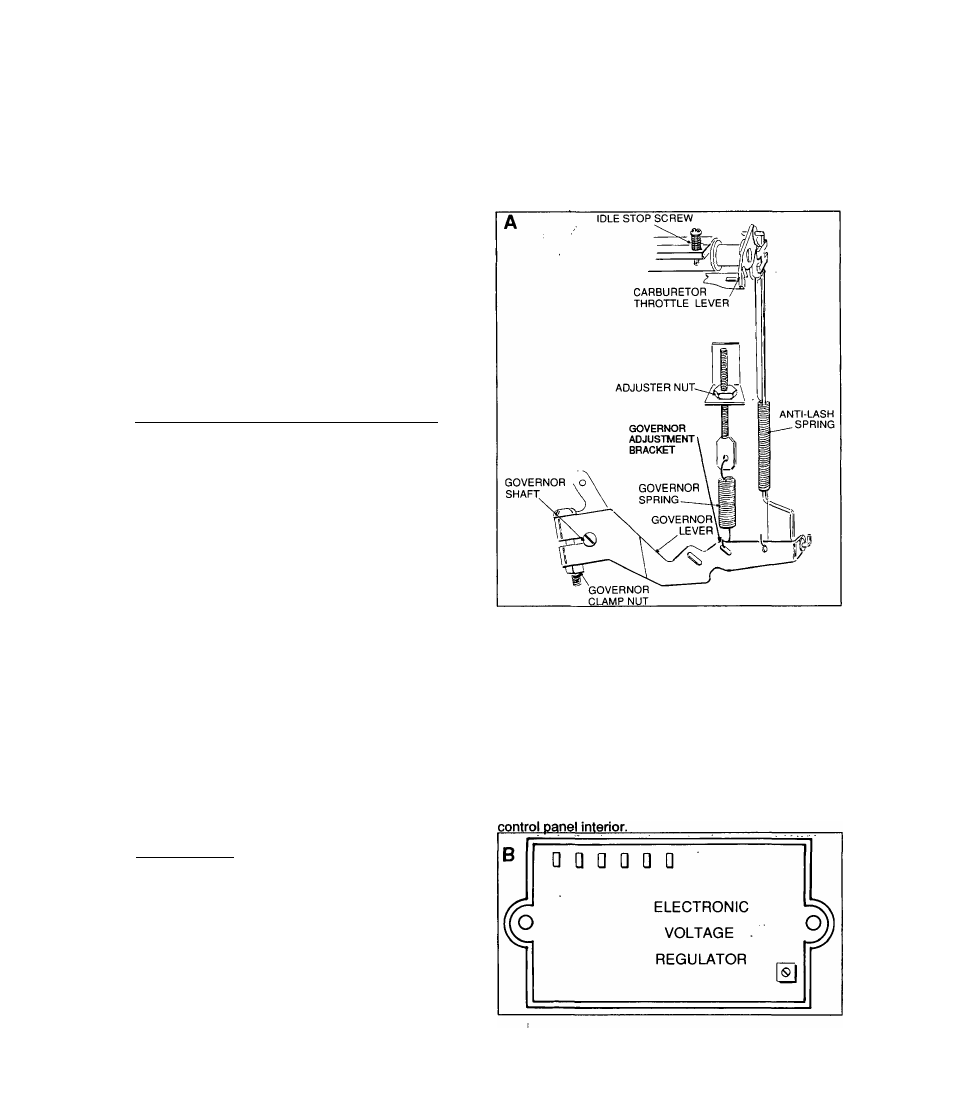

Engine Governor Adjustment

A

Also see ROTOR ROTATIONAL SPEED on Page 4

of this Manual. The engine governor is generally ad

justed to deliver a generator a-c output frequency of

61-62 Hz, with no electricai loads connected to the gen

erator. Following the no-load adjustment of engine

speed, unit operation shouid be checked with a ioad

applied. Adjust the engine governor as foiiows:

1. Visually inspect ANTI-LASH SPRING, make sure it is

not broken or disengaged. Spring ends must be hooked

into GOVERNOR LEVER at bottom end and into car

buretor THROTTLE LEVER at top.

2. Loosen GOVERNOR CLAMP NUT.

3. Push spring end of GOVERNOR LEVER ail the way

up, to wide open throttle position. While holding the

LEVER down, insert a screwdriver into siotted end of

GOVERNOR

SHAFT

and

rotate

SHAFT

fuliy

counterclockwise.

Then,

tighten

the

GOVERNOR

CLAMP NUT to 100 inch-pounds of torque.

CAUTION!: Governor shaft MUST be rotated fully

counterclockwise with throttle wide open or full

governor travel will not be reached. Governor clamp

nut must be tight Or full governor travel may be lost

due to vibration.__________________________________

4.

Connect an accurate a-c frequency meter and

voltmeter across generator a-c output leads T2 (white)

and T3 (black) for Series NP45G/NP55G; or across ieads

T1 (red) and T2 (white) for Series NP65G. See Step 3

under Probiem No. 6 on Page 19. (Check A-C VOLTAGE

AND FREQUENCY).

5. Start the engine. Let it stabilize and warm up for a few

minutes with NO ELECTRiCAL LOADS APPLiED TO

GENERATOR.

6. Check a-c frequency; it should be 61 -63 Hz. If not, turn

ADJUSTER NUT until frequency is correct.

7. With governed speed at 61-63 Hz (no-load), check

voltage reading. Voltage should be 122-126 volts. If not,

adjustment of the Voltage Regulator is required.

Voltage Regulator Adjustment

CAUTION: DO NOT adjust the Voltage Regulator

until a-c output frequency Is correct. See ENGINE

GOVERNOR ADJUSTMENT.

B

Check that a-c frequency is correct, as outiined in

ENGiNE GOVERNOR ADJUSTMENT. If frequency Is

within stated limit (61-63 Hz), a-c voltage output should

be 122-126 volts. If voltage is not correct, adjust the

Voitage Regulator by turning the VOLTAGE ADJUST

potentiometer slowly until a-c voltage Is within the stated

limits. Voltage regulator is mounted in the generator

24