X battery charge 7 winding, Problem no. 4 - engine starts hard, runs rough – Generac Power Systems IM Series User Manual

Page 20

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Step 4 - Check Control Relay CR1

Test Procedure: Refer to Step 6 under Problem No. 1.

Test Results:

A. Control Relay CR1 checks GOOD: Go to Step 5.

B. Control Relay CR1 checks BAD: Replace Control

Relay CR1.

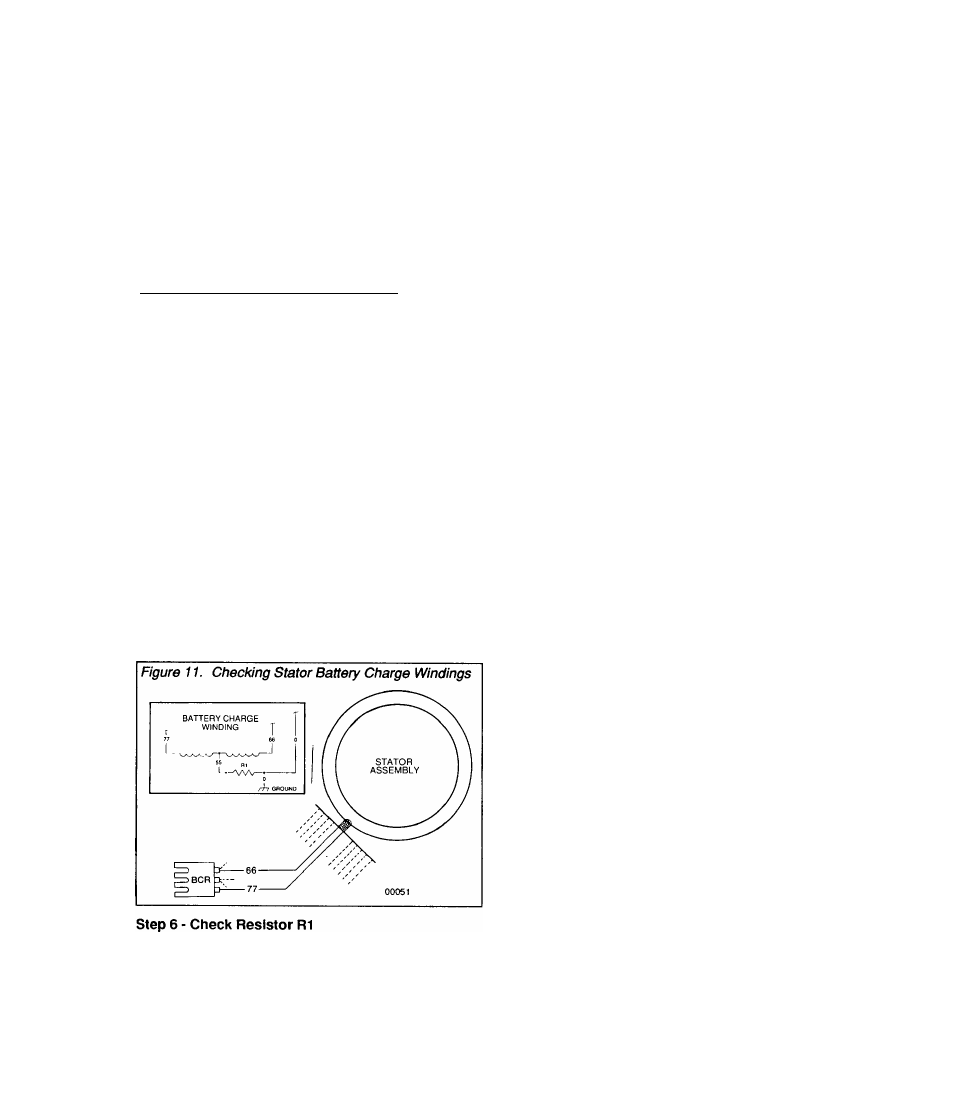

Step 5 - Check Stator Battery Charge Windings

NOTE: The Volt-Ohm-Mllllammeter (VOM) used to

test Stator windings must be accurate. Recom-

mended Is a digital meter of high accuracy.__________

Test Procedure: Disconnect Wires 66 and 77 (Fig. 11)

from the Battery Charge Rectifier BCR terminais. Set a

VOM to its "Rxl" scaie and zero the meter. Connect the

meter test ieads across the terminal ends of Wires 66 and

77, just removed from Battery Charge Rectifier BCR. The

VOM should indicate Stator Battery Charge Winding

resistance, as follows:

Series NP45G = 0.12 ohm

Series NP55G = 0.09 Ohm

Series NP65G = 0.07 ohm

All test readings are plus or minus 10%.

Now, set the VOM to its "Rxl 0,000" scale and zero the

meter. Connect one VOM test lead to terminal end of

Wire 66, remaining test lead to a dean frame ground. No

upscale movement of the meter should be noted (infinity).

Test Results:

A. Battery Charge Winding checks GOOD: Go to Step 6

B. Battery Charge Winding checks BAD: Replace Stator

Assembly.

Test Procedure: Inside the generator panel, locate

Resistor R1 (Fig. 12). Test wire 0 (between Resistor R1

and frame ground connection) for an open condition.

Correct open condition, if necessary, before proceeding.

Disconnect Wire 55 form the Resistor to prevent interac

tion. Set a VOM to Ks "Rxl" scale and zero the meter.

Connect the first meter test probe to the Wire 55 terminal

of Resistor. Connect second test probe to a clean frame

ground. Meter should indicate about 1 ohm (plus or minus

5%).

Test Results:

A. Resistor R1 checks GOOD: Repeat Steps 1 through 4

under Problem No. 3.

B. Resistor R1 checks BAD: Replace Resistor R1.

Figure 12. Resistor R1

X BATTERY CHARGE

7

WINDING

66

-T

55

R1

00053

rh

GROUND

Problem No. 4 - Engine Starts Hard, Runs

Rough

Step 1 - Check Engine Ignition System

Test Procedure: Refer to ENGINE TROUBLESHOOT

ING section. Also see ENGINE SERVICE MANUAL.

Test Results:

A. Ignition system checks GOOD: Go to Step 2.

B. Ignition system checks BAD: Repair or replace defec

tive component(s).

Step 2 - Check Carburetlon

Test Procedure: See ENGINE TROUBLESHOOTING

section. Also see ENGINE SERVICE MANUAL.

Test Results:

A. Checks GOOD: Go to Step 3.

B. Checks BAD: Adjust, repair or replace as necessary.

Step 3 - Check Engine Compression

Test Procedure: Refer to ENGINE TROUBLESHOOT

ING section. Also see ENGINE SERVICE MANUAL.

Test Results:

A. Engine checks GOOD: Go to Step 4.

B. Engine checks BAD: Repair as required.

18