Generac Power Systems IM Series User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Test Between Isolated Windings:- To test between iso

lated Stator windings, proceed as follows:

1. Connect RED lead of Hi-Pot tester to terminal end of

Wire 11, BLACK test lead to Wire 2 terminal end.

2. Turn tester switch ON and check that Pilot Light is ON.

3. Set Voltage Selector Switch to 1500 voits- APPLY

VOLTAGE FOR ONE SECOND ONLY. Observe tester

Breakdown lamp. Turn tester switch OFF and reset Vol

tage Selector Switch to 500 volts.

Test Between Parallel Windings:- Test between paral

lel Stator windings as follows:

1. Set tester Voltage Selector Switch to 500 volts.

2. Connect tester RED test lead to Wire #11, BLACK test

lead to Wire 33.

3. Turn tester switch ON and check that Pilot Light is ON.

4. Apply voltage for one second while observing the

Breakdown lamp. Then, turn tester switch OFF.

RESULTS: If tester Breakdown lamp comes ON

during any one second test, clean and dry the stator.

Then, repeat the breakdown test. If Breakdown lamp

Illuminates after drying, replace the Stator Assemb

ly-

Testing Rotor Insulation for Breakdown

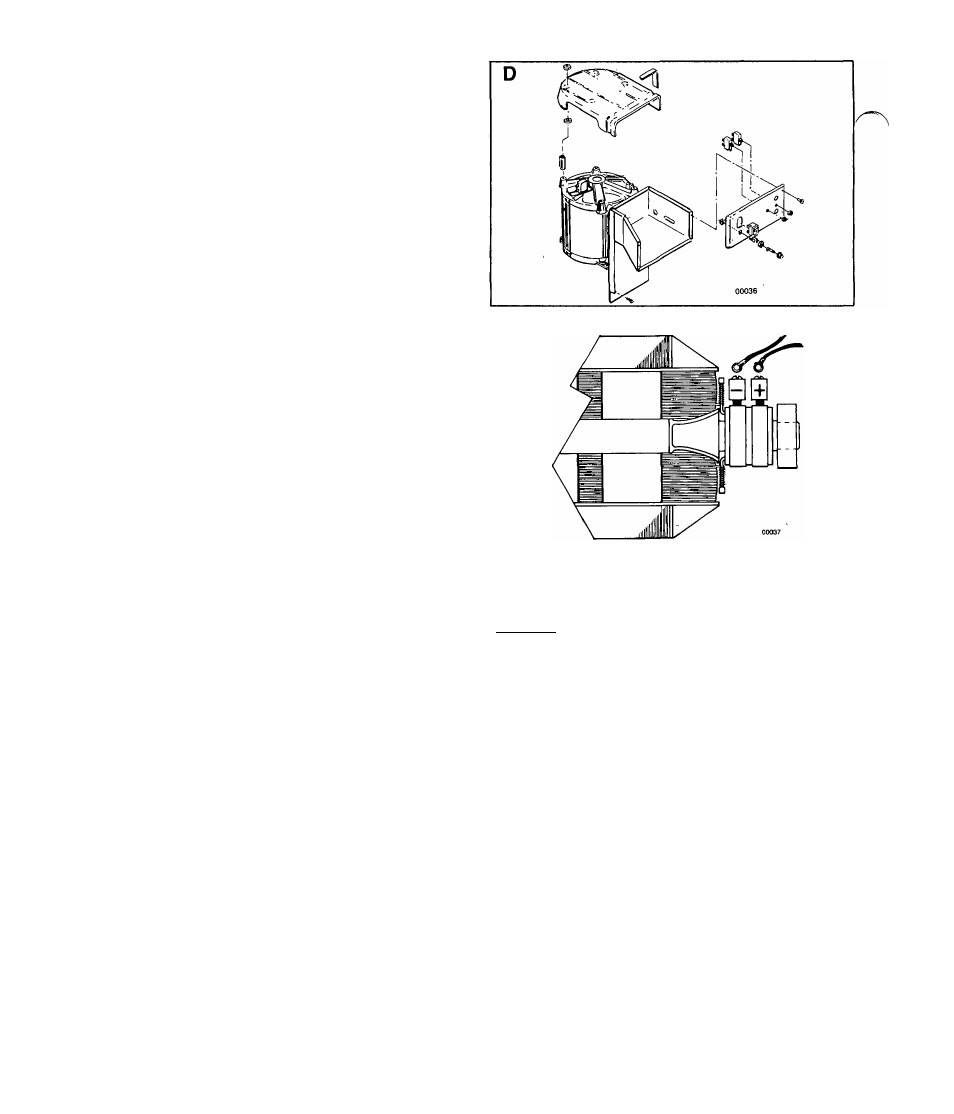

D

Remove generator cover to gain access to the Rotor

slip rings and brushes. ,

E

Remove all wires that connect to the Brushes. Then,

test Rotor insulation as follows:

1. Connect tester RED test lead to the positive {+) Rotor

slip ring (nearest the Rotor bearing).

2. Connect BLACK test lead to a clean frame ground.

3. Turn tester switch OFF.

4. Plug tester into a 120 volts wall socket.

5. Set Voltage Selector Switch on tester to 500 volts.

6. Turn tester switch ON and check that Pilot Light is ON.

7. Set Voltage Selector Switch to 1250 volts and observe

the tester breakdown lamp. Then, turn tester switch OFF.

RESULTS:-

If

tester

breakdown

lamp

lllumlates

during the 1 second test, drying of the generator may

be necessary. After drying, repeat the Hl-Pot test. If

Rotor windings fall the second test (after drying),

replace the Rotor assembly.

Cleaning the Generator

Removed caked on or greasy dirt with a soft brush or a

clean, damp doth. A vacuum system may be used to pick

up loosened dirt. Loose dust and dirt may also be

removed using low pressure, dried air (25 psi maximum).

CAUTION!: Do NOT use a forceful spray of water to

clean generator. Some of the water will be retained

on generator windings and will cause serious

problems.______________________________________

Drying the Generator

1. Open the main drcuit breaker or main line switch. NO

ELECTRICAL LOADS MUST BE CONNECTED TO

GENERATOR WHILE DRYING.

2. Remove the generator cover (see illustration "B" on

previous page).

3.

Disconnect Wire #4 from the Electronic Voltage

Regulator.

4. Provide an external source to blow warm, dry air

through the generator. Do NOT exceed 185' F. (85* C.).

5. Start the engine, let it run for 2 to 3 hours.

6. Stop the engine and retest Stator and Rotor windings.

10