Ctls70mfb rfsphnsibiutips, Blade removal (see fig. 13), To sharpen blade (see fig. 14) – Poulan 163598 User Manual

Page 14: Battery, V-belts, Transaxle cooling, Transaxle pump fluid, Blade care

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CtlS70MFB RFSPHNSIBIUTIPS

ob;

afe [V ri

when performinq any mainte-

A mil

ir П ;,-д

ll *P ^ liljlrtl f O[ j.^.í I 4 dl_ I if I r

C I

u" I'iltll Ml >-Atx| dt ihfclljr

r г Д’Jl d

I d-

r • -*| t< f- I bh^iT ifi th- >d!(i .-riri AdJII',.

iHt-n«' illifi C.| l4lb

'■ MairiTaiii p ojjn ги р.еь

pii

* m ali tires (See “PROD-

lj(

1

^-,pf='- |F|r Д j jONS ri, nage 3 of this manual).

«- I tk-p iirpd free uf qd-iuline oil or insect control chemi-

(als which ran harm, r jLbet

•

An i Э unp tfiiip Jffcf ruts, sharp objects and

hazard' that mav tire damage.

NOTE 1 ^eal tife ропНиге_ and prevent flat tires due to

slo V lecl-b hre sealant тэ/ oe purchased from your local

parto aealcr иге ealant also prevents tire dry rot and

romosic

1

BLADE CARE

For best results mower blades must be kept sharp. Re

place bent or damaged blades.

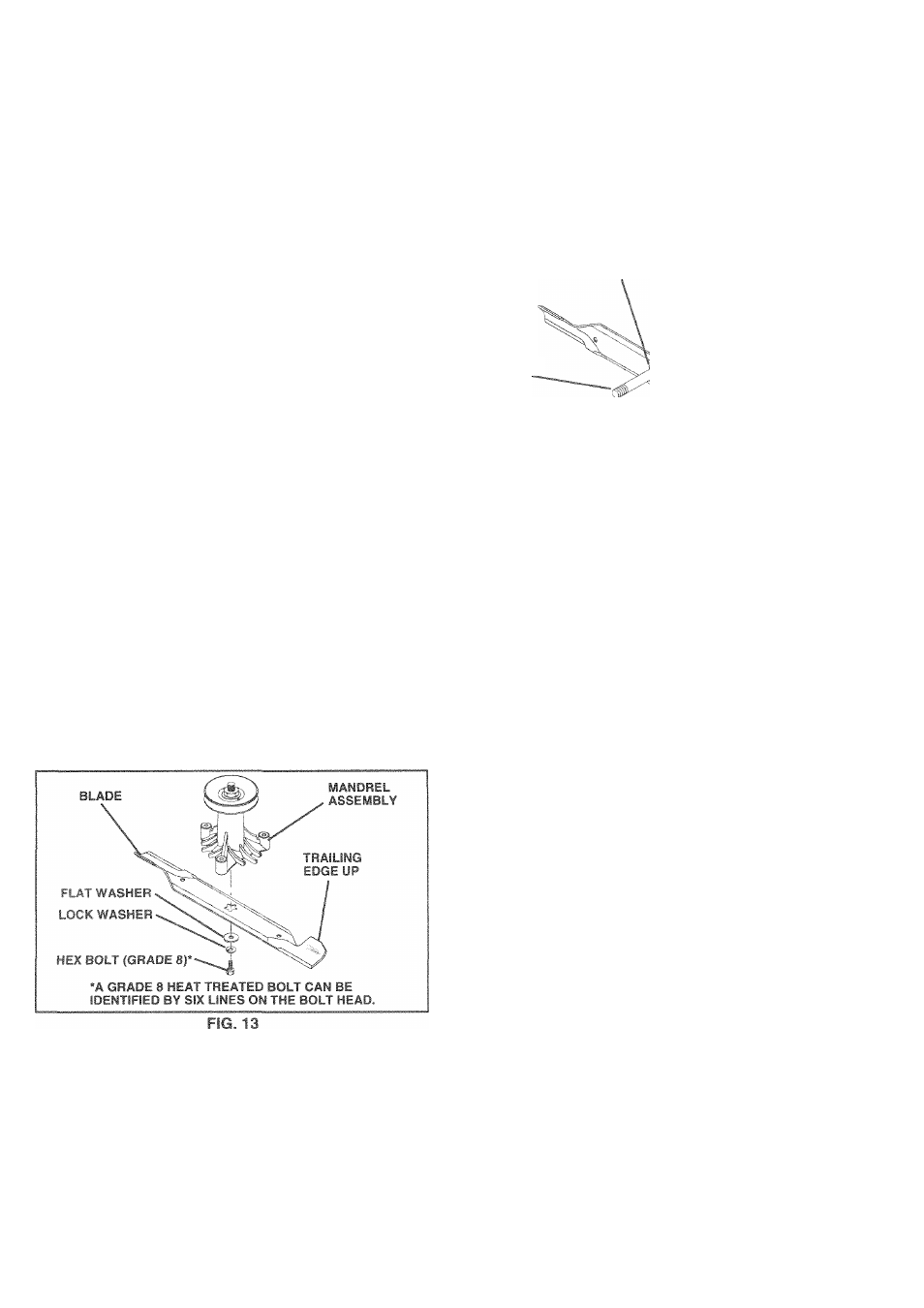

BLADE REMOVAL (See Fig. 13)

•

Raise mower to highest position to allow access to

blades.

•

Remove hex bolt, lockwasherandflatwashersecuring

blade,

•

Instali new or resharpened blade with trailing edge up

towards deck as shown.

•

Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

•

Tighten bolt securely (30-35 Ft. Lbs. torque).

IMPORTANT; BLADE BOLT IS GRADE 8 HEATTREATED.

NOTE: We do not recommend sharpening blade - but if you

do, be

sure the

blade is balanced.

TO SHARPEN BLADE (See Fig. 14)

Care should be taken to keep the blade balanced. An

unbalanced blade will cause excessive vibration and even

tual damage to mower and engine.

•

The blade can be sharpened with a file or on a grinding

wheel. Do not attempt to sharpen while on the mower.

•

To check blade balance, you will need a 5/8“ diameter

steel bolt, pin, or a cone balancer. (When using a cone

balancer, follow the instructions supplied with bal

ancer).

• Slide blade on to an unthreaded portion of the steel bolt

( i ) 'i ' ■ to, I i jr«i ^

S ■ I I M I I

ii|ti

'

k

I’ll

tll,r .

If blade is balanced, it should remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

NOTE: Do not use a nail for balancing blade. The lobes of

tb . nt*-t »• I /

.

CENTER

5/8“ BOLT

OR PIN

BATTERY

Your tractor ha.s a batter/ charging system which is suffi

cient for norma! use However, periodic charging of the

battery with an automotive charger will extend its life.

•

Keep battery and terminals clean

•

Keep batierv bolts light.

•

Keep small vent holes open.

•

Recharge at 6-10 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to “leak” power.

•

Open battery box door.

•

Disconnect BLACK battery cable first then RED bat

tery cable and remove battery from tractor.

•

Rinse the battery with plain water and dry.

» Clean terminals and battery cable ends with wire brush

until bright.

•

Coat terminals with grease or petroleum jelly.

•

Reinstall battery (See “CONNECT BATTERY” in the

Assembly section of this manual).

V-BELTS

Check V-belts for deterioration and wear after 100 hours of

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin to slip from wear.

TRANSAXLE COOLING

The fan and cooling fins of transmission should be kept

clean to assure proper cooling.

Do not attempt to clean fan or transmission while engine is

running or while the transmission is hot.

•

Inspect cooling fan to be sure fan blades are intact and

clean.

•

Inspect cooling fins for dirt, grass clippings and other

materials. To prevent damage to seals, do not use

compressed air or high pressure sprayer to clean

cooling fins.

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory and fluid mainte

nance is not required forthe life of the transaxle. Should the

transaxle ever leak or require searicing, contact your near

est authorized service center/department.