Generac DUARDIAN 04077-2 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION

Section

2

— O peration

Guardian Air-cooled 6 kW, 8 kW and 10 kW Generators

2.1

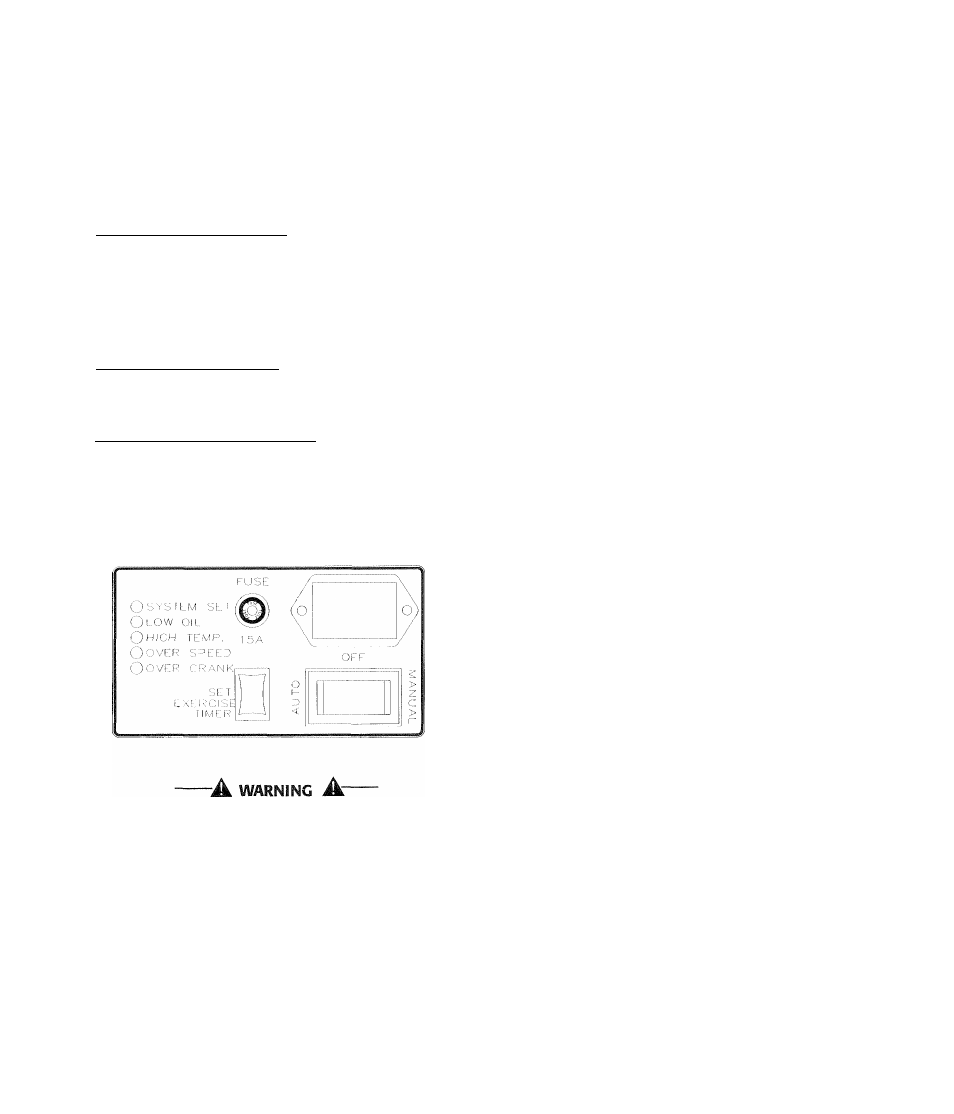

USING THE AUTO/OFF/IVIANUAL

SWITCH

(FIGURE 2.1)

♦ 2.1.1 "AUTO" POSITION________________

Selecting this switch position activates fully auto

matic system operation. It also allows you to start

and exercise the engine every 14 days with the set

ting of the exercise timer (see section 2.5). This

position also is used for remote starting, when it is

set up.

♦ 2.1.2 "OFF" POSITION

____________

This switch position shuts down the engine. This

position also prevents automatic operation.

♦ 2.1.3 "MANUAL" POSITION_____________

Set the switch to MANUAL to crank and start the

engine. Transfer to standby power will not occur

unless there is a utility failure.

Figure

2.1 - Generator Control Panel

With the switch set to AUTO, the engine may

crank and start at any time without warning.

Such automatic starting normally occurs when

utility power source voltage drops below a pre

set level or during the normal exercise cycle. To

prevent possible injury that might be caused by

such sudden starts, always set the switch to

OFF and remove the fuse before working on or

around the generator or transfer switch. Then,

place a "Do Not Operate" tag on the generator

panel and on the transfer switch.

2.2

AUTOIVIATIC TRANSFER

OPERATION

To select automatic operation, do the following:

1. Make sure the transfer switch main contacts

are set to their “Utility” position, i.e., loads con

nected to the utility power source (Figure 2.2).

2. Be sure that normal utility power source voltage

is available to transfer switch terminal lugs N1

and N2.

3. Set the generator’s Auto/Off/Manual switch to

AUTO.

4. Set the generator’s main circuit breaker to its

ON (or closed) position.

With the preceding steps complete, the generator

will start automatically when utility source voltage

drops below a preset level. After the unit starts,

loads are transferred to the standby power source.

Refer to “Sequence of Automatic Operation.”

2.3

SEQUENCE OF

AUTOMATIC OPERATION

The generator’s control panel houses a control logic

circuit board. This board constantly monitors utili

ty power source voltage. Should that voltage drop

below a preset level, circuit board action will signal

the engine to crank and start. After the engine

starts, the circuit board signals the transfer switch

to activate and connect load circuits to the standby

power supply (load terminal lugs

T1/T2

connect to

terminal lugs E1/E2).

Upon restoration of utility source voltage above a

preset level, generator circuit board action signals

the transfer switch to transfer loads back to that

power supply. After retransfer, the engine is sig

nalled to shut down.

The actual sequence of operation is controlled by

sensors and timers on a control logic circuit board,

as follows:

A. Utility Voltage Dropout Sensor

• This sensor monitors utility source voltage.

• If utility source voltage drops below about 60

percent of the nominal supply voltage, the sen

sor energizes a 15-second timer.

® Once the timer has expired, the engine will

crank and start.

B. Engine Warm-up Time Delay

• This mechanism lets the engine warm up for

about 10 seconds before the load is transferred

to a standby source.

C. Standby Voltage Sensor

« This sensor monitors generator AC output volt

age. When the voltage has reached 50 percent

of the nominal rated voltage, transfer to stand

by can occur.

Generac* Power Systems, Inc.