Changing the friction wheel rubber, Belt removal and replacement – MTD 315B User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

6. Remove the other blade in the same manner.

Replace or sharpen blades. If sharpening, make

certain to remove an equal amount from each

blade. Reassemble in reverse order.

NOTE:

Make certain blades are reassembled with the

sharp edge facing upward, as viewed from the access

plate opening.

CHANGING THE FRICTION WHEEL RUBBER

The rubber on the friction wheel is subject to wear

and should be checked after 50 hours of operation,

and periodically thereafter. Replace friction wheel

rubber if any signs of wear or cracking are found.

1. Drain the gasoline and oil from the chipper-

vacuum.

2. Tip the unit backward so it rests on the handles.

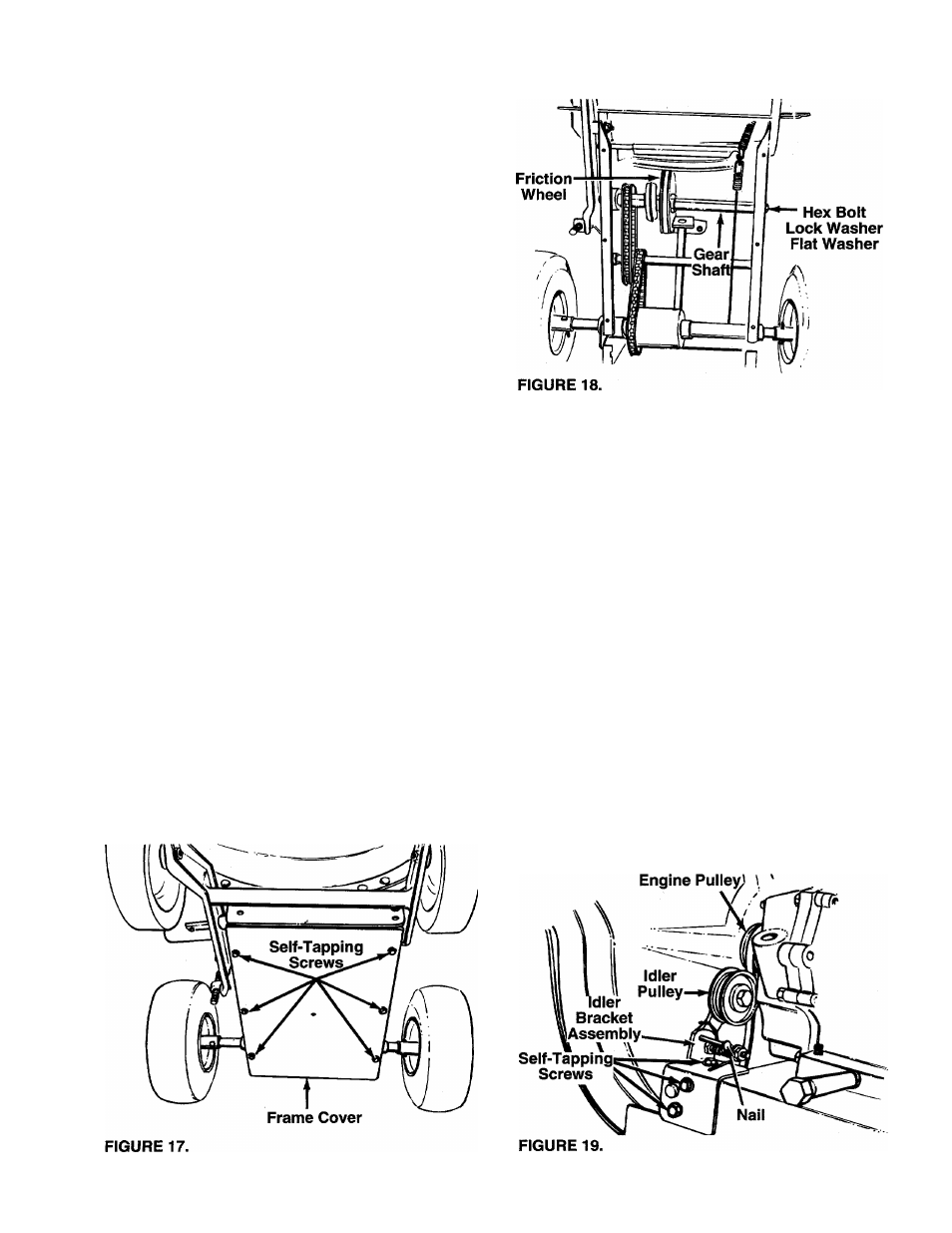

3. Remove the frame cover by removing eight self

tapping screws from underneath the chipper-

vacuum. See figure 17.

4. Remove the gear shaft from the unit by removing

the hex bolts, lock washers and flat washers from

each side of the frame. See figure 18. Hold the

friction wheel assembly, and slide the gear shaft

out of the unit toward the right side.

5. Remove the six screws from the friction wheel

assembly (three from each side). Remove the

friction wheel rubber from between the friction

wheel plate.

6. Reassemble new friction wheel rubber to the fric

tion wheel assembly, tightening the six screws in

rotation and with equal force.

7. Slide the friction wheel assembly up onto the shift

mechanism, then slide the gear shaft back into

the unit. Reassemble in reverse order.

8. Readjust the clutch cable. Refer to adjustment

section.

BELT REMOVAL AND REPLACEMENT

A

WARNING: Disconnect the spark plug

wire and move away from the spark plug.

1

.

Remove the plastic belt cover on the front of the

engine by removing two self-tapping screws.

Refer to figure 14.

Drain the gasoline and oil from the chipper-

vacuum.

3. Tip the unit backward so that it rests on the

handles.

Remove the frame cover by removing eight self

tapping screws from underneath the chipper-

vacuum. Refer to figure 17.

Remove the idler pulley bracket as follows. (See

figure 19.)

a. Take the tension off thé belt by pivoting the

idler pulley toward you, and line up the holes in

the idler bracket assembly. Insert a nail or simi

lar object through the holes to hold the idler

pulley in this position.

b. Remove three self-tapping screws, and lift off

the idler bracket assembly.

2

.

4.

5.

10