Flexible pump coupler, Tire pressure, Installation of tire to rim – MTD 242-632-000 User Manual

Page 12: Off-season storage

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

The

spark plug

should be cleaned and the gap reset

once

a

season.

Spark

plug

replacement

is

ecom-

mended

at

the

start

of

each

season;

check

engine

manual for correct plug type and gap specificat on.

Clean the engine

regularly with a cloth or brush.

Keep the cooling system (blower housing area) clean

to

permit

proper

air

circulation

which

is

esseitial

to

engine performance and life. Be certain to rerr ove all

dirt and combustible debris from muffler area.

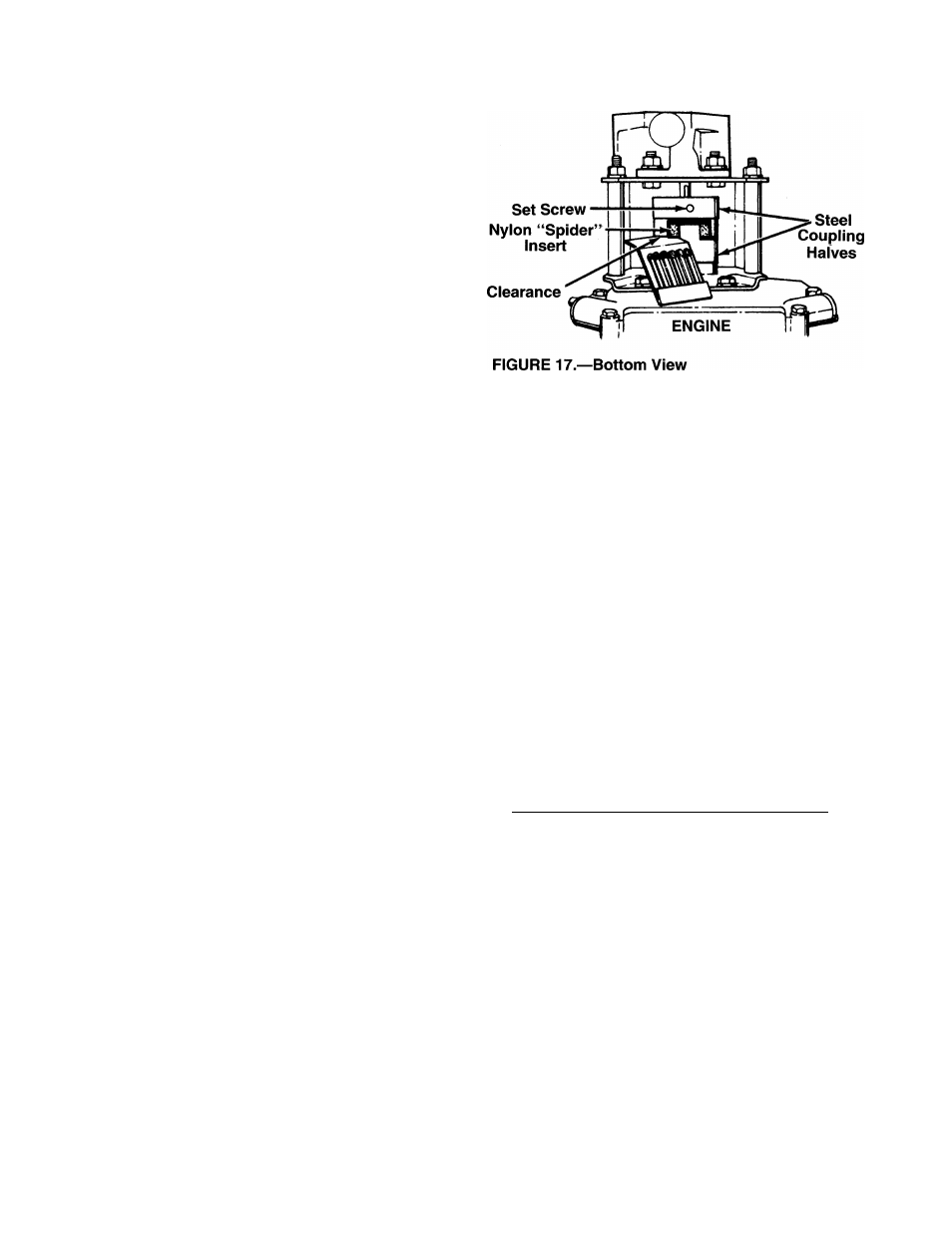

PUMP

FLEXIBLE PUMP COUPLER

The flexible pump coupler is a nylon “spider” insert,

located

between

the

pump

and

engine

sha

't.

The

alignment is very critical. Over a period of tine, the

coupler will harden and deteriorate. For a re place

ment

flexible

pump

coupler,

order

part

number

717-

0891.

IMPORTANT:

Never hit the pump shaft in

anf

man

ner, as any blow will cause permanent damage to the

pump.

When

replacing

the

flexible

pump

coupling,

p

oceed

as follows.

1.

Place the coupling half onto the engine shaft.

Make certain there is clearance between tf e cou

pling half and the engine. Tighten the set screw.

2.

Mount the pump onto the coupling support brack

et. Tighten securely.

3.

Carefully

slide

coupling

half

onto

pump

shaft

(make certain set screw is loose). Slide tie key

into place on the shaft.

4.

Install the nylon “spider” insert into coupling half

on the engine shaft.

5.

Place the coupling shield in position on the hex

bolts. Rotate the keyway on the pump shaft so it

is toward the bottom.

6

.

Attach the coupling support bracket to the hex

bolts, carefully sliding the coupling half o\ er the

“spider”

insert.

Secure

coupling

shield

and

cou

pling support bracket with lock washers and hex

nuts. Tighten securely.

7.

Adjust the two coupling halves (steel) so t lere is

between

.

010

”

and

.060”

clearance

between

the

two halves (at least the thickness of a matchbook

cover,

up

to

1/16”

maximum).

See

figure

17.

Tighten the set screw in the coupling half on the

pump shaft.

NOTE:

Make certain proper clearance is ob tained

before tightening set screw.

TIRE PRESSURE

Check

sidewall

of

tire

for

manufacturer’s

recommend

ed maximum tire pressure. If this information does not

appear on your tire, maximum tire pressure under any

circumstances

is

30

p.s.i.

Equal

pressure

should

be

maintained on both tires.

INSTALLATION OF TIRE TO RIM

A

WARNING: The following procedure must

be followed when removing or installing

a tire to the rim.

1. Be certain rim is clean and free of rust.

2. Lubricate both the tire and rim generously.

3.

Never inflate to over 30 p.s.i. to seat beads.

Excessive

pressure

when

seating

beads

may

cause tire/rim assembly to burst with force suffi

cient to cause serious injury.

OFF-SEASON STORAGE

If the log splitter will not be used for a period longer

than 30 days, the following steps should be taken to

prepare the log splitter for storage.

1.

Clean the engine and the entire log splitter thor

oughly.

2.

Refer to the engine manual for correct engine

storage

instructions.

Follow instructions care

fully.

3.

Wipe unit with an oiled rag to prevent rust, espe

cially wedge and beam.

4.

Store unit in a clean, dry area. Do not store next

to corrosive materials, such as fertilizer.

NOTE:

When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rustproof the equipment by coating with a

light oil or silicone.

12