Carburetor adjustment, Hydraulic filter, Beam and splitting wedge – MTD 242-632-000 User Manual

Page 11: Hdse clamps, Maintenance, Reservdir fluid, Engine

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Hex Bolts

Bolts

the bottom of the reservoir tank, and drain the fluid

into a suitable container. Refill using only Dexron II

automatic

transmission

fluid

or

10W

non-foaming

hydraulic

fluid,

as

instructed

in

the

“Initial

Preparation”

section

of

this

manual,

page

8

.

Also,

make certain to change the hydraulic filter.

NOTE:

Drain the fluid and flush the reservoir tank and

hoses with kerosene whenever any repair work is per

formed on the tank, hydraulic pump or valve.

Contaminants in the fluid will damage the hydraulic

components. (Should be performed by an authorized

service dealer.)

FIGURE 16.

A

WARNING: Use extreme caution when

working with kerosene, as it is an

extremely flammable fluid.

CARBURETOR ADJUSTMENT

A

WARNING: If any adjustments are made

to the engine while the engine is running

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

Minor carburetor adjustment may be required to com

pensate

for

differences

in

fuel,

temperature,

altitude

or load. Improper adjustment will cause stalling when

splitter

is

under

load,

hard

starting

and

higher

fuel

consumption.

Refer

to

the

separate

engine

manual

packed

with

your log splitter for carburetor adjustment information.

NOTE:

A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor beforeadjusting carburetor. Do not

make unnecessary adjustments. Factory settings are

satisfactory for most applaications and conditions.

HYDRAULIC FILTER

Change the hydraulic filter every 50 hours of opera

tion. Use only a 10 micron hydraulic filter. Order part

number 723-0405.

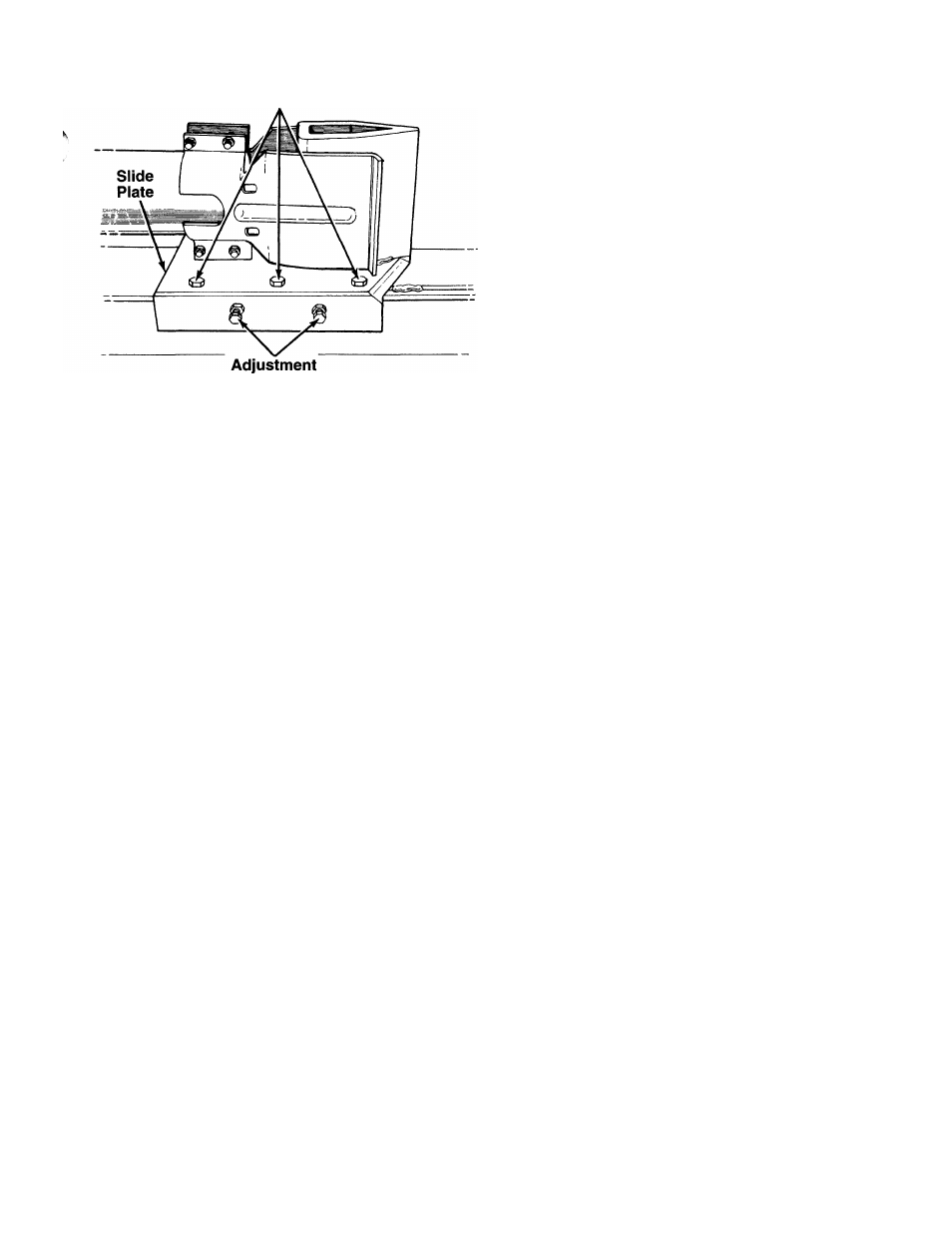

BEAM AND SPLITTING WEDGE

Lubricate both sides of the beam where it contacts the

splitting

wedge

with

engine

oil

before

each

use

to

obtain

years

of

service.

However,

normal

wear

will

occur. The wedge plate on the log splitter is designed

so the gibs on the side of the wedge plate can be eas

ily removed and rotated and/or turned over for even

wear. Make certain to readjust the adjustment bolts so

wedge

moves

freely,

but

no

excess

space

exists

between the wedge plate and beam.

HDSE CLAMPS

Check the hose clamps on the suction hose (attached

to

bottom

of

the

pump)

for

proper

tightness

before

each use. Check the hose clamps on the return hose

at least once a season.

MAINTENANCE

A

WARNING: Always stop the engine and

disconnect the spark plug wire before

performing any maintenance or repairs.

RESERVDIR FLUID

Check the hydraulic fluid level in the log splitter reser

voir tank before each use. Fluid level should be 11/2”

to

2

" from the top of the tank.

Change the hydraulic fluid in the reservoir every 100

hours of operation. Disconnect the suction hose from

ENGINE

Refer to the separate engine manual for all engine

maintenance instructions.

Maintain

engine oil

as

instructed

in

the

separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service

air cleaner

every 25 hours under normal con

ditions. Clean

every

few hours under extremely dusty

conditions.

Poor

engine

performance

and

flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner refer to the separate

engine manual packed with your unit.

11