Assembly instructions, Unpacking, Installation of wheels – MTD 630 thru 635 User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY INSTRUCTIONS

Tools Required for Assembly

(1) Soft Hammer or Mallet

(2) 9/16" Wrenches*

(2) 1/2" Wrenches*

(1) 7/16" Wrench*

(1) Adjustable Wrench

(1) Screwdriver

(1) Pliers

(1) Knife

(1) Cutters

*Adjustable Wrenches may be used.

Other Materials Required for Assembly:

Engine Oil

Unleaded Gasoline

Dexron II Automatic Transmission Fluid or 10W

Non-Foaming Hydraulic Fluid

Model 630—Approximately 4 Gallons

Model 635—Approximately 7.6 Gallons

Reservoir

Engine and Tank AsMmbiy

Pump Assembly »

1

Hitch

-Assembly

Tongue Assembly

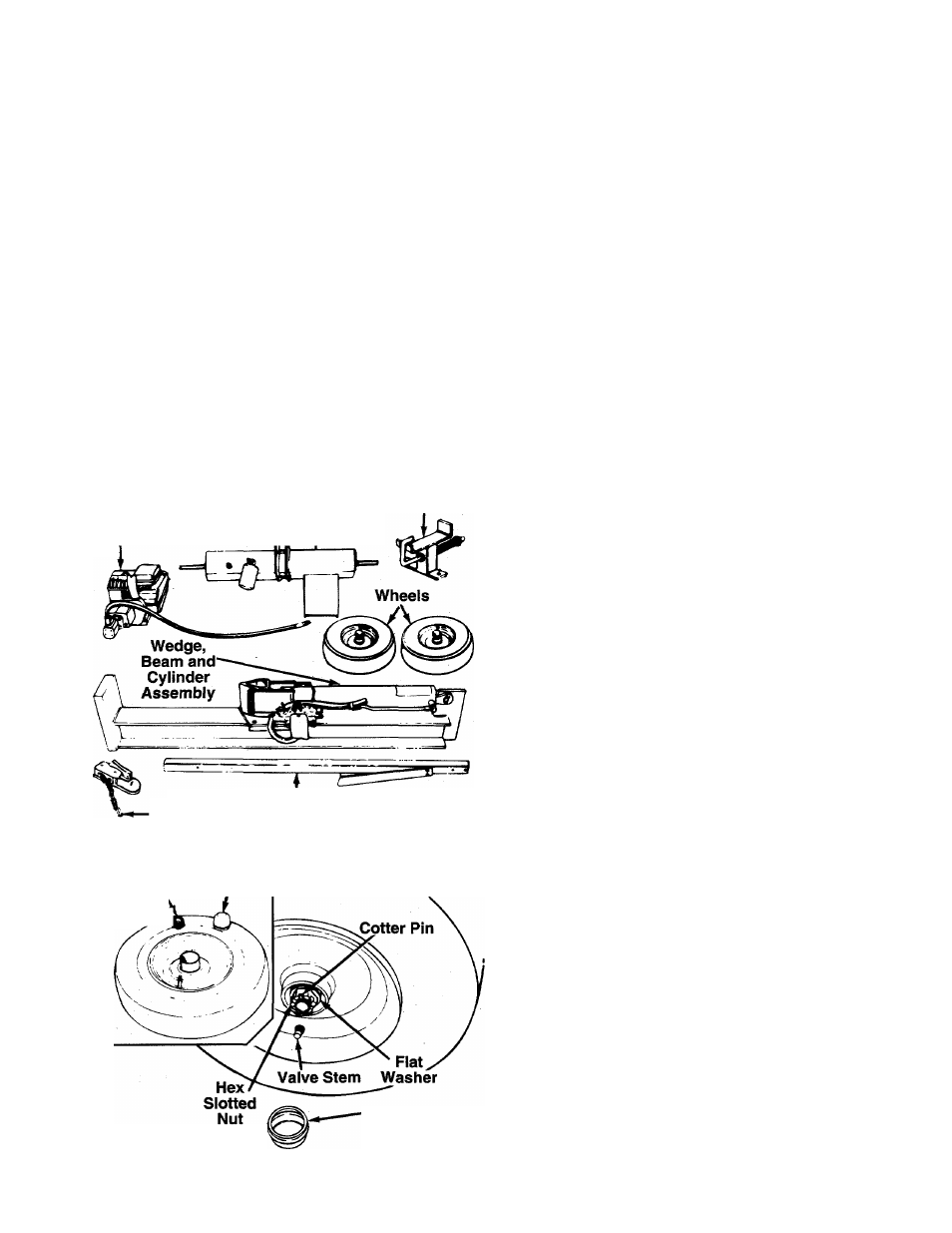

FIGURE 1.

Tapered

Roller^

Bearing]

Hub Cap

Hub Cap

FIGURE 2.

IMPORTANT; This unit has been shipped without

gasoline or oil in the engine. Be certain to service

engine with gasoline and oil before operating your

log splitter. Refer to the separate engine manual.

UNPACKING

A

WARNING: Exercise extreme caution as

parts are very heavy. Mechanical han

dling equipment should be used, or suffi

cient people to prevent injury.

Remove the log splitter parts from the carton by cut

ting the corners of the carton. Unbolt parts bolted to

bottom of carton. Make certain all parts and literature

have been removed from the carton before the carton

is discarded. Most of the hardware for assembly of

the log splitter has been placed in position on the vari

ous parts.

Parts in Carton (See figure 1)

Reservoir Tank Assembly (Bolted to bottom of

carton)

Engine and Pump Assembly (Bolted to bottom of

carton)—Connected to Wedge, Beam and

Cylinder Assembly by Pressure Hose

Wedge, Beam and Cylinder Assembly

Tongue Assembly

Wheels

Fenders (Not Shown—Model 635 Only)

Small box which contains:

Hitch Assembly

Beam Support/Latch Bracket

Plastic hardware bag (4 bolts, washers, nuts)

Plastic bag containing two grease seals and two

hub caps

Plastic bag containing grease and four roller

bearings

INSTALLATION OF WHEELS

Attach the wheels to the reservoir tank assembly as

follows. See figure 2.

1. Block up the reservoir tank assembly about 8

inches.

2. Remove the rolier bearings, grease seals and

hub caps from the plastic bags.

- 3. Pack the tapered roller bearings with wheel bear

ing grease. Work grease between the rollers.

Insert a bearing (smaller end first) into the inside

hub of each wheel (valve stem is on the outside of

the wheel). Insert a grease seal with open side fac

ing inward into the inside hub of each wheel. Tap

on using a soft hammer or mallet. Outside surface

of seal should be even with the end of the hub.

NOTE: A large socket can be placed against the

grease seal to aid in properly seating the seal.

4. Remove the cotter pin, hex slotted nut and flat

washer from each axle. Place one wheel on each

axle, hub side toward the log splitter (valve stem

facing outward).

5. Place a tapered roller bearing on each axle (make

certain they have been packed with grease).