MTD 1850 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Step 3. Place your foot on the rear of the depth bar

and apply pressure. The belts will go slack.

Step 4. Remove the REAR belt first and ALLOW IT TO

FORM

A

LOOP

AROUND

THE

VARIABLE

SPEED PULLEY.

Step 5. Slide the center section of the variable-speed

pulley towards the engine. See Figure 4-7.

Step 6. Remove the FORWARD belt from the engine

pulley and the variable-speed pulley.

NOTE

By following this order of belt removal,

it is not necessary to remove the belt

guard on the varible-speed pulley.

Step 7. Remove the rear belt from the variable-speed

pulley.

Step 8. Reassemble with the new belts.

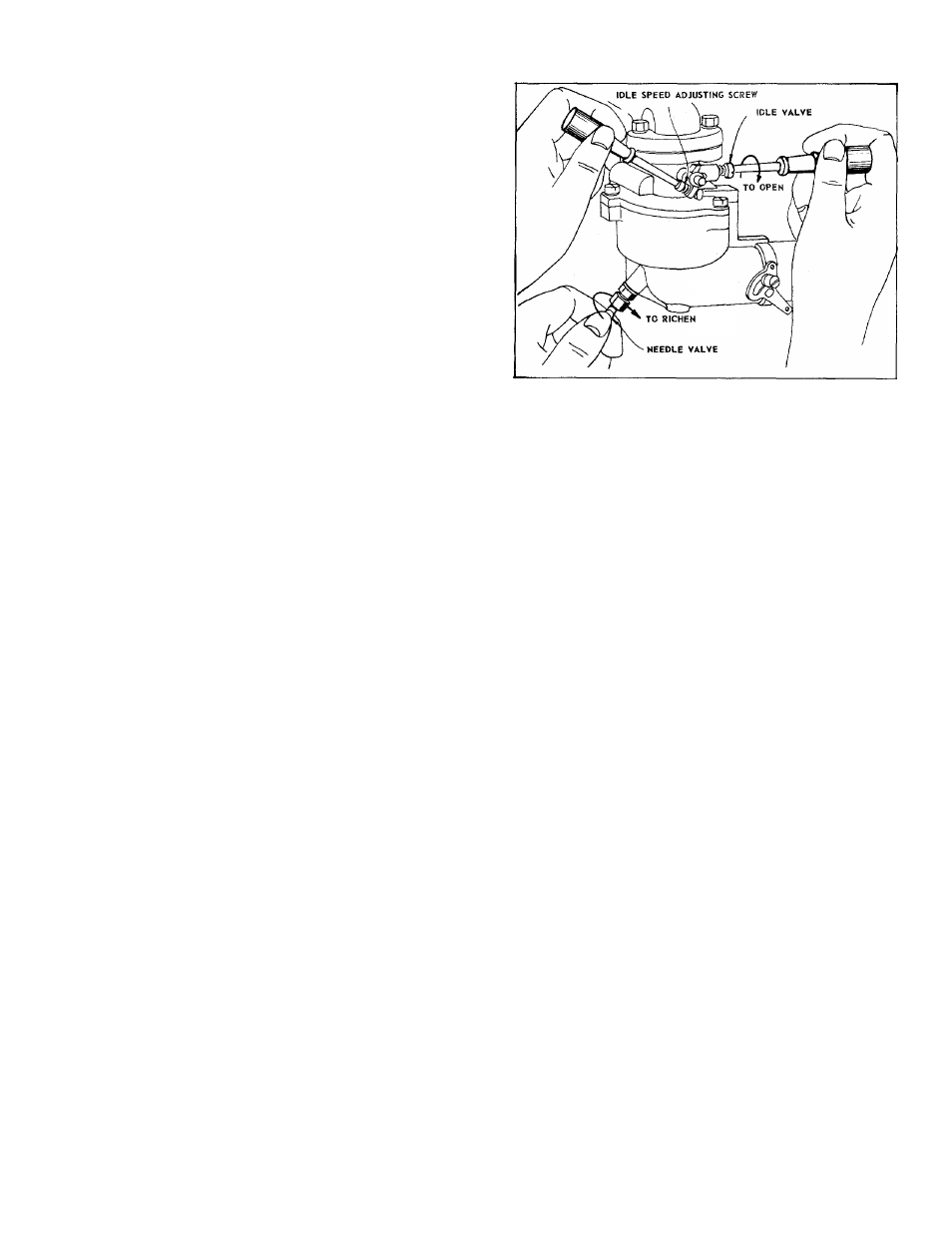

FIGURE 4-9. CARBURETOR ADJUSTMENT

4-n. ADJUSTING THE CARBURETOR

Minor

carburetor

adjustment

may

be

required

to

compensate

for

differences

in

fuel,

temperature,

alti

tude and load.

To Adjust Carburetor:

Turn needle valve clockwise until it just closes. See

Figure 4-9.

CAUTION

Valve may be damaged by turning it in

too far.

Now open needle valve IV

2

turns counter-clockwise.

Close idle valve in same manner and open

V

a

to %

turns. This initial adjustment will permit the engine to

be started and warmed up prior to final adjustment.

Final Adjustment;

Turn needle valve in until engine misses (lean mix

ture) then turn it out past smooth operating point until

engine

runs

unevenly

(rich

mixture).

Now

turn

needle

valve to the mid-point between rich and lean so the en

gine runs smoothly.

Hold throttle at idle position and set idle speed ad

justing screw until fast idle is obtained (1750 RPM).

Hold

throttle

in

idle

position

and

turn

idle

valve

in

(lean) and out (rich) until engine idles smoothly. Then

reset idle speed adjusting screw so that engine idles

at

1750

RPM.

Release

throttle—engine

should

accel

erate

without

hesitation

or

sputtering.

If

engine

does

not

accelerate

properly,

the

carburetor

should

be

re

adjusted to a slightly richer mixture.

4-12. ADJUSTING CARBURETOR CHOKE

Proper choke and stop switch operation is depend

ent upon proper adjustment of remote controls on the

powered equipment.

To Check The Operation Of The Choke:

Step 1. Remove the air cleaner.

Step 2. Pull the throttle control all the way out to the

CHOKE

position.

See

Figure

2-1.

The

choke

should be closed.

Step 3. The engine should shut off when the throttle

control is all the way in. (STOP position.)

To Adjust;

Place

remote

control

lever

on

equipment

in

FAST

(high

speed)

position.

Loosen

control

casing

clamp

screw "B." Move control casing "A" and wire until lever

"D" touches choke operating link at "C." Tighten cas

ing clamp screw "B." Replace air cleaner. See Figure

4-10.

4-4