Section 4 maintenance, 1. crankcase oil, A. oil check – MTD 1850 User Manual

Page 11: 2. chain case lubrication, Note, 3. chain adjustment, Figure 4-1. oil fill plug, B. oil change, 4. air filter

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION 4

MAINTENANCE

4-1. CRANKCASE OIL

To

ensure

maximum

engine

performance,

perform

the following periodic maintenance:

a. Oil Check

Check the oil level in the crankcase before each use

of the machine and after every two hours of opration.

The oil level shall be over-flowing at the oil fill plug.

See figure 4-1.

OIL FILL PLUG

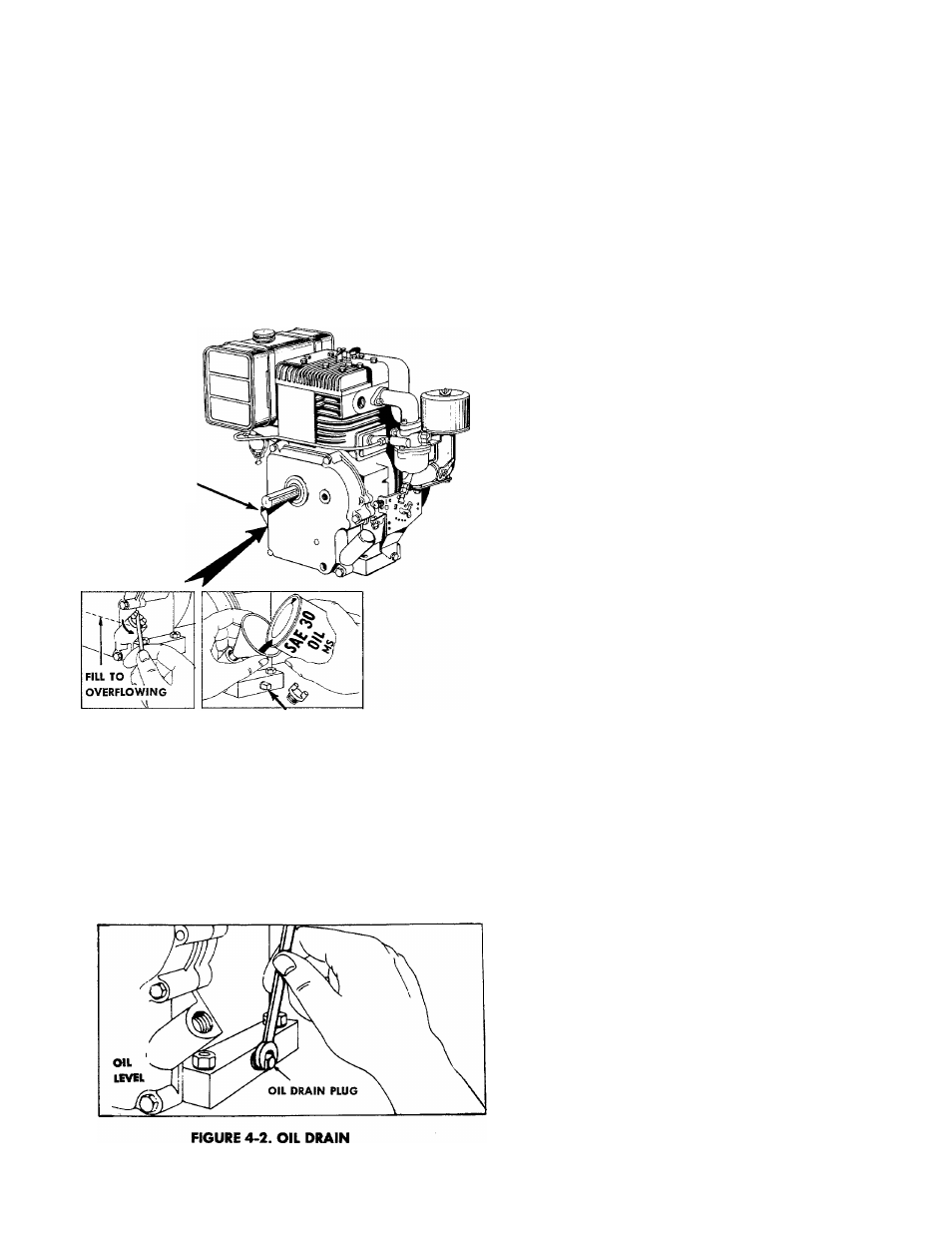

OIL DRAIN

Step 1. With the machine on level ground, place a

suitable metal container under the oil drain

plug, then remove the drain plug.

Step 2. After the oil has been drained completely

from the crankcase, replace the drain plug

and tighten.

Step 3. Refill crankcase with 2% pints of SAE 30 en

gine oil (A.P.I. class MS). Pour the oil slowly

to eliminate airlock.

4-2. CHAIN CASE LUBRICATION

The

chain

is

permanently

lubricated

and

requires

no further lubrication unless the case is disassembled

for repair.

If the case is disassembled, clean the chain with

kerosene, allow it to dry and work a high temperature

grease, such as Lubriplate No. 310 into the chain.

NOTE

A 4 oz container of Lubriplate No. 310

is

available

under

part

number

727-136.

4-3. CHAIN ADJUSTMENT

No chain adjustment is necessary.

FIGURE 4-1. OIL FILL PLUG

b. Oil Change

After the first two hours of operating a new engine,

drain the oil (see figure 4-2) from the crankcase while

engine

is

still hot

and

refill

crankcase with new

oil;

thereafter change the oil after every 25 hours of opera

tion. This procedure ensures for minimum wear of en-

gin

parts

and

provides

for

virtually

trouble-free

oper

ation. To change the oil, proceed as follows:

4-4. AIR FILTER

Under

normal

operating

conditions,

the

air

cleaner,

located

on

top

of

the

carburetor,

must

be

serviced

after

every

ten

hours

of use.

Under extremely

dusty

operating

conditions, the air cleaner must be serviced

after every hour of operation. See Figure 4-3.

Step 1. Remove the wing nut and cover.

Step 2. Lift off foam element from support base.

Step 3. Remove metal support tube assembly (screen

and two metal caps) from foam element by

compressing the foam element.

4-1