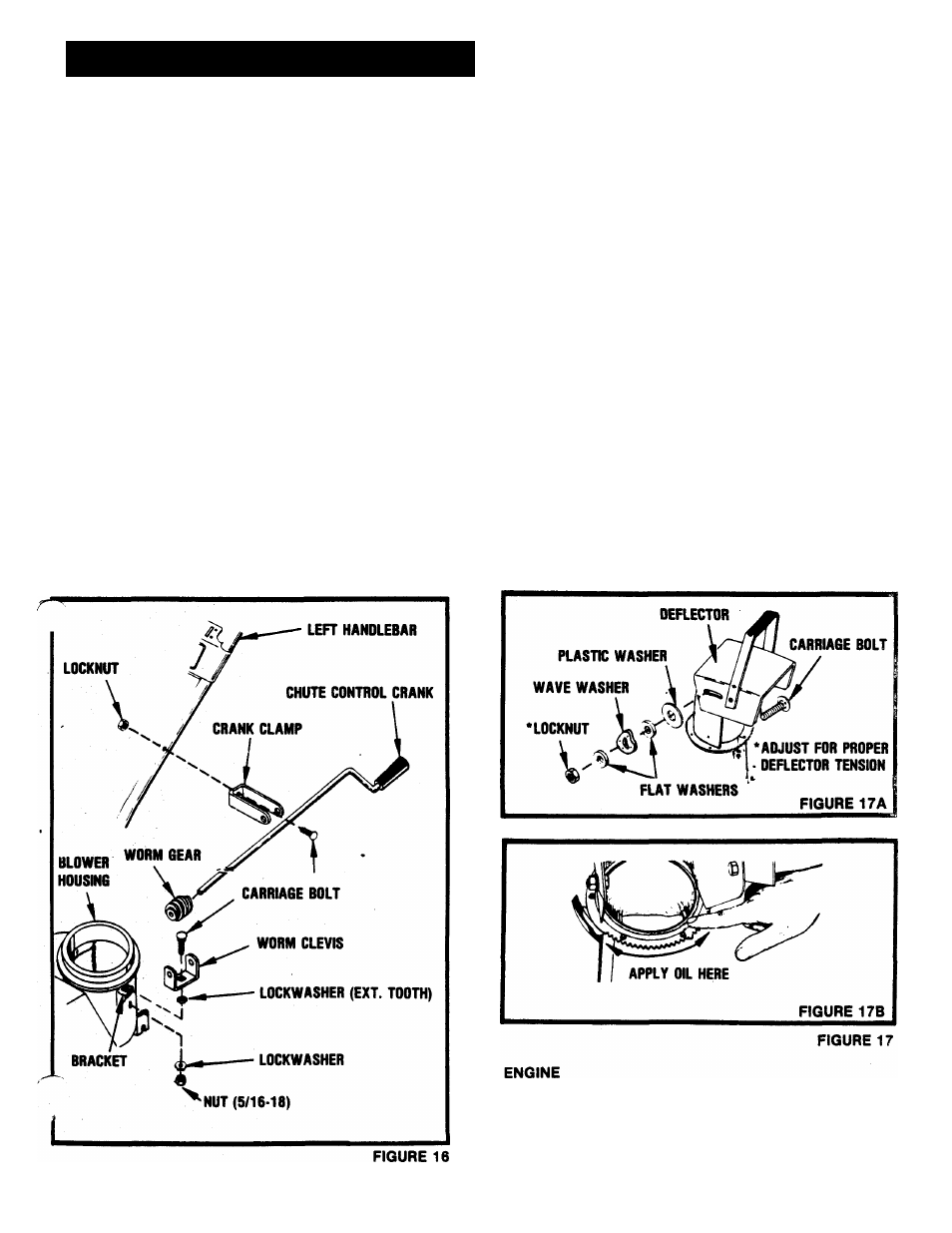

Assembly & pre-service, Attachment clutch - continued, Chute control crank — figure 16 – Ariens 932007 User Manual

Page 15: Deflector - figure 17, Blower gear case

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY & PRE-SERVICE

ATTACHMENT CLUTCH - CONTINUED

after attachment clutch handle is disengaged (up posi

tion). If this is not achieved, check blower idler adjust

ment

according

to

paragraph

"d"

(attachment

drive

belt tension may be too tight) and belt finger adjust

ment (paragraph "e"). Reinstall belt cover.

CAUTION:

PROPER

FUNCTION

OF

ATTACHMENT

CLUTCH

CAN

BE ASSURED ONLY WHEN THE PREVIOUS STEPS IN “ATTACH

MENT CLUTCH” SECTION HAVE BEEN PERFORMED.

CHUTE CONTROL CRANK — FIGURE 16

The chute control crank is shipped fully assembled and In place

in the bracket. Install as follows: Bolt the crank clamp in place

on the left handlebar. See Figure 16.

Position the worm clevis on the bracket on the blower housing.

Place

external

tooth

lockwasher

between

worm

clevis

and

bracket. Adjust in slot so that there is a little clearance between

worm and gear teeth on blower collar.

Secure the worm clevis with the carriage bolt (already in place on

the

clevis).

Use

a

lockwasher

(63023)

and

a

5/16-18

nut

(65015) under the bracket. See Figure 16.

Rotate the discharge chute through its full travel to see that it

turns easily. Readjust the position of the worm clevis, if re

quired. Oil discharge chute, see Figure 17B.

DEFLECTOR - FIGURE 17

The deflector is shipped in place on the discharge chute but

must be raised into operating position. Remove the locking hard

ware from the discharge chute. Raise the deflector up into posi

tion. Re-install the hardware as shown In Figure 17A. Adjust the

nut to apply sufficient tension so the deflector can be easily

moved by hand but will still hold position when blowing snow.

BLOWER GEAR CASE

The blower gear case is factory lubricated and should require no

lubrication by the dealer.

The blower gear case Is lubricated with Ariens Liquid Grease

(Part

No.

000070).

This

grease

will

not

flow

at

lower

temperatures. It is therefore difficult to check the lubricant level.

Best method for checking is to place the unit in a warm location

overnight. This aliows the grease to flow to level. Check the

lubrication by removing the filler plug on the side of the gear

case just above the left auger shaft. Lubrication shouid be even

with the hoie with the machine sitting level. It may be necessary

to Insert a wire into the hoie to check levei. The unit will not be

damaged by over lubricating.

Fill

crankcase

with

oil

as

recommended

in

Engine

Manufacturer’s Instructions supplied with the product. Check oil

level before each use and change oil regularly according to

Engine Manufacturer’s Instructions.

-1 5