Lubrication, Engine, Sno-thro traction drive - figure 10 – Ariens 932007 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

LUBRICATION

ENGINE

Fill

Crankcase

with

oil

as

recommended

in

Engine

Manufacturer’s Instructions supplied with the product. Check oil

level before each use and change oil regularly according to

Engine Manufacturer’s Instructions.

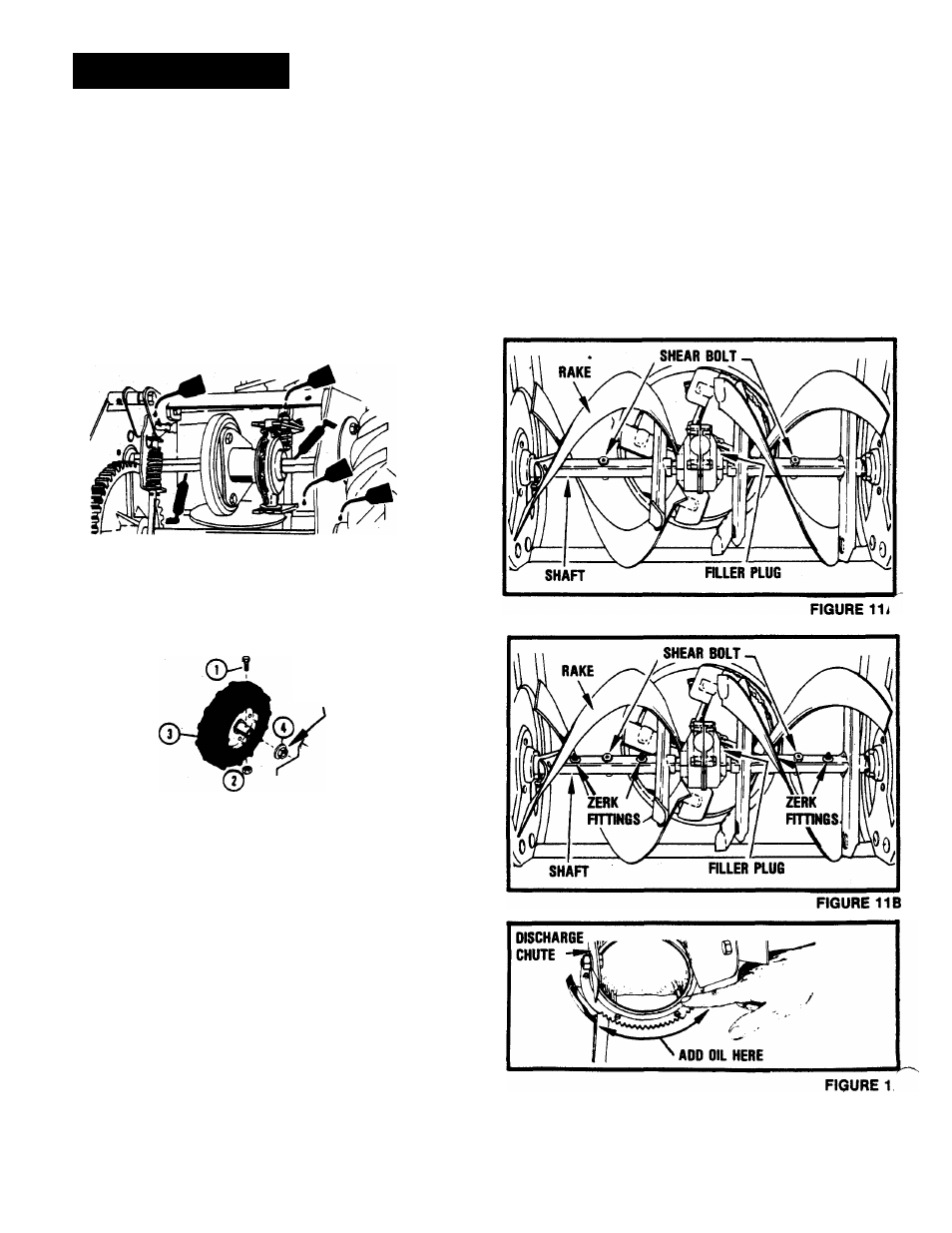

SNO-THRO TRACTION DRIVE - FIGURE 10

At the start of each operating season, grease the hex shaft as in

dicated in Figure 10. Put a few drops of oil on the Speed Selector

linkage and other linkage points. Lubricate the bushings on the

axle as indicated in Figure 10.

NOTE:

BEFORE

LUBRICATING

THE

BUSHINGS

ON

AXLE

(BETWEEN

THE

WHEEL

AND

FRAME)

BE

SURE

TO

CLEAN

THE

INNER

SURFACES

OF

THE

BUSHINGS.

REMOVE

THE

CAP

SCREW

(1)

AND

LOCKNUT

(2).

REMOVE

WHEEL

(3)

FROM AXLE. CLEAN INSIDE OF BUSHING (4) AND ADD OIL

TO INNER BUSHING SURFACE. REPLACE WHEEL.

CLEAN & OIL

FIGURE 10

SNO-THRO UNIT - FIGURES 11 & 12

The blower gear case is lubricated with Ariens Liquid Grease

(Part

No.

000070).

This

grease

will

not

flow

at

lower

temperatures, it is therefore difficult to check the lubricant level.

Best method for checking is to place the unit in a warm location

overnight. This allows the grease to flow to level. Check the

lubrication by removing the filler plug on the side of the gear

case just above the left auger shaft. Lubrication should be even

with the hole with the machine sitting level, it may be necessary

to insert a wire into the hole to check level. The unit will not be

damaged by over lubricating.

NOTE:

OIL

CAN

(PUMP-TYPE)

MAY

BE

USED

TO

LUBRICATE

WITH ARIENS LIQUID GREASE.

Some models are equipped with zerk fittings on the rake shaft.

See Figure 11B. For those models that do not have zerk fittings,

oil rake shaft periodically or each time a shear bolt is replaced. At

the end of the season, remove shear bolts, oil rake shaft through

shear bolt holes, turn rakes on shaft several times and replace^

shear bolts. See Figure 11 A.

On models equipped with zerk fittings on the rake shaft it will be

necessary to re-grease the rake shaft zerk fittings provided each

time a shear bolt is replaced and/or at the end of the season. Be

sure to rotate the rakes on the shaft several times after applying

grease. See Figure 11B.

Oil the Discharge Chute with several drops of oil See Figure 12.

Rotate the Discharge Chute after applying oil to spread oil over

the Discharge Chute gear teeth to prevent rust and provide

smooth operation.

-

1 0

-