Tiller lubrication, Check for gear oil leaks, Check hardware – Troy-Bilt 12214-5.5HP User Manual

Page 19: Transmission gear oil service, A. to check the transmission gear oil level, Check for oil leaks check hardware, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Sections: Maintenance

WARNING

Before inspecting, cleaning or servicing the unit, shut off engine, wait for all ^

parts to come to a complete stop, disconnect spark plug wire and move wire away from spark

plug. Failure to follow these instructions can result in serious personal injury or

property damage.

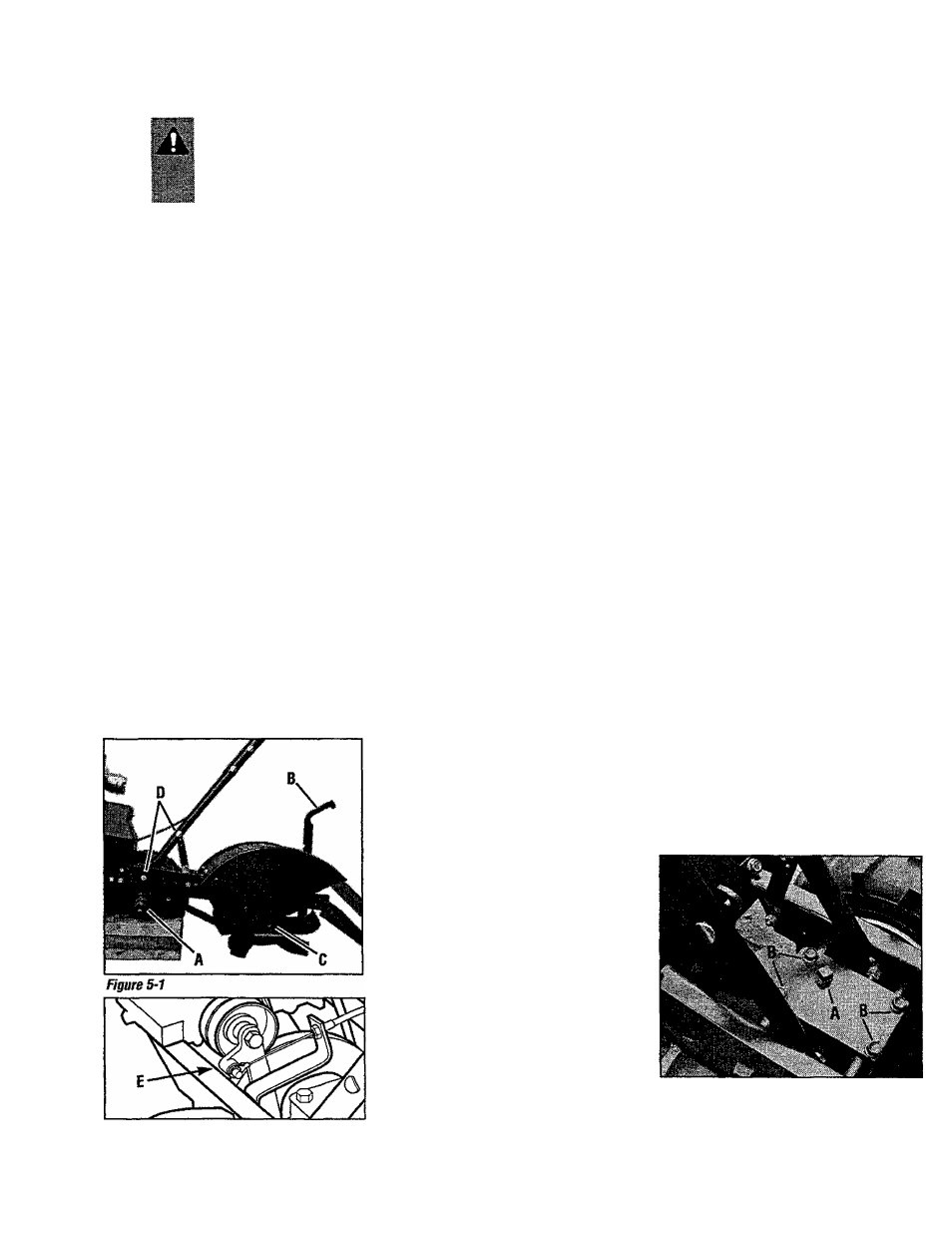

TILLER LUBRICATION

Proper lubrication of the tiller is an

essentia! part of maintenance. After

every 10 operating hours, oil or grease

the lubrication points shown in Figures 5-

1 and 5-1A and described below.

Use general purpose lubricating oil (#30

weight motor oil Is suitable) and general

purpose grease (grease that contains a

metal lubricant is preferred, if available).

• Remove wheels, clean wheel shaft (A,

Fig. 5-1) and apply light coating of

grease to shaft.

• Grease back, front and sides of Depth

Regulator Lever (B, Fig. 5-1).

• Remove tines, clean tine shafts (C, Fig.

5-1) and apply light coating of grease to

shaft.

• Oil the handlebar height adjustment

screws and the handlebar attaching

screws (D, Fig. 5-1).

• Lightly oil the shifting mechanism pivot

points (E, Fig. 5-1 A). Do not get oil on

the belt or belt groove of the pulley.

Figure 5-1A

CHECK FOR GEAR OIL LEAKS

Before each use, check the transmission

housing (and the ground beneath the

unit) for any sign of a pear oil leak.

A little seepage around a cover or an oil

seal is usually harmless. However, it oil

drips overnight, then immediate attention

is needed as ignoring a leak can result in

severe transmission damage.

If a cover is leaking, try tightening any

loose screws. If the screws are tight, a

new gasket or oil seal may be needed. If

the leak is from around a shaft and oil

seal, the oil seal probably needs to be

replaced. See your authorized dealer or

contact the factory for service or advice.

IMPORTANT:

Never operate the tiller if

the transmission is low on gear oil.

Check the oil level after every 30 hours of

operation and whenever there is any oil

leakage.

CHECK HARDWARE

After every 10 operating hours, thor- ,

oughly inspect the unit for any loose or

missing screws, bolts and other fasteners.

Tighten or replace the fasteners as

needed. Be sure to check the screws

underneath the tine hood that secure the

transmission cover and the Depth

Regulator Lever to the transmission.

CHECK TIRE PRESSURE (on units

equipped with pneumatic tires)

Check the air pressure in both tires.

Deflate or inflate both tires evenly to15-20

PSI (pounds per square inch). Be sure

that both tires have the same air pressure

or the unit will tend to pull to one side.

TRANSMISSION GEAR OIL SERVICE

Check the transmission gear oil level after

every 30 hours of operation or whenever

you notice an oil leak.

IMPORTANT:

Operating the tiller when the transmission

is low on oil can result in severe damage.

A. To Check the Transmission

Gear Oil level:

1. The transmission must be cool (warm

operating temperatures will provide an

incorrect oil level reading).

2. The transmission must be level.

3. Remove the oil fill plug (A, Fig. 5-2)

and look into the oil fill hole. The main

drive shaft is visible inside the hole.

4.

The oil level is correct if it is approxi

mately halfway up the side of the drive

shaft

5. If the oil level is low, add gear oil as

described next. If the oil level is okay,

securely replace the oil fill plug.

6. If only a few ounces of gear oil is

needed, use API rated GL-4 or GL-5 gear

oil having a viscosity of SAE140, SAE

85W-140 or SAE 80W-90. If refilling an

empty transmission, use only GL-4

transmission gear oil having a viscosity of

SAE 85W-140 or SAE 140.

IMPORTANT:

Do not use automatic

transmission fluid or motor oil in the

transmission.

7. Slowly pour gear oil into the oil fill

hole until it reaches the halfway point on

the drive shaft. Check frequently while

pouring to avoid overfilling.

8. Securely replace the oil fill plug.

Figure 5-2: Remove oil fill plug (A) to check

gear oil level and to add gear oil. Remove

four cover screws (B) to drain gear oil.

19