Ariens Sno-Thros 924000 Series User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CHUTE CRANK ADJUSTMENT

In the event the chute crank fails to rotate freely, loosen the

nut securing the worm clevis to the bracket. This hole in the

bracket is slotted to permit adjustment. Position the worm

so there is a little clearance between worm and the gear

teeth on the blower. Tighten the nut. Rotate the discharge

chute through its full travel to see that it turns easily. Re

adjust if required. Uubricate as described under LUBRICATION

for smooth operation.

BELT REPLACEMENT

A

CAUTION

Since replacing the belts will involve turning the engine over

with the starter, and the engine might accidentaily start, re

sulting in injury, the spark plug wire MUST be disconnected

during this procedure.

The drive belt and the attachment drive belt are both accessible

by removing the blower housing as follows;

1. Remove the hair pin cotter in the chute crarik assembly.

Separate the chute crank.

2. Remove the two flanged whizlock screws securing the belt

guard to the tractor. Remove the belt guard.

NOTE:

Tipping

the

tractor

back

on

the

handlebars

when

separating the units may result in bending the bottom cover.

To avoid diis situation, either tip the unit up on the blower

housing and remove the bottom cover before separating the

units; or support the handlebars so the tractor does not tip all

the way over; then lift off the blower housing.

3. Remove the cap screws on each side that secures the blower

housing to the frame. As the blower housing and tractor

are tipped apart, roll the belt off the engine sheave between

the sheave and belt finger. This can be easily done by

pulling the recoii starter rope to rotate the engine sheave.

With the beit disconnected, the biower housing may then

be lifted from the frame.

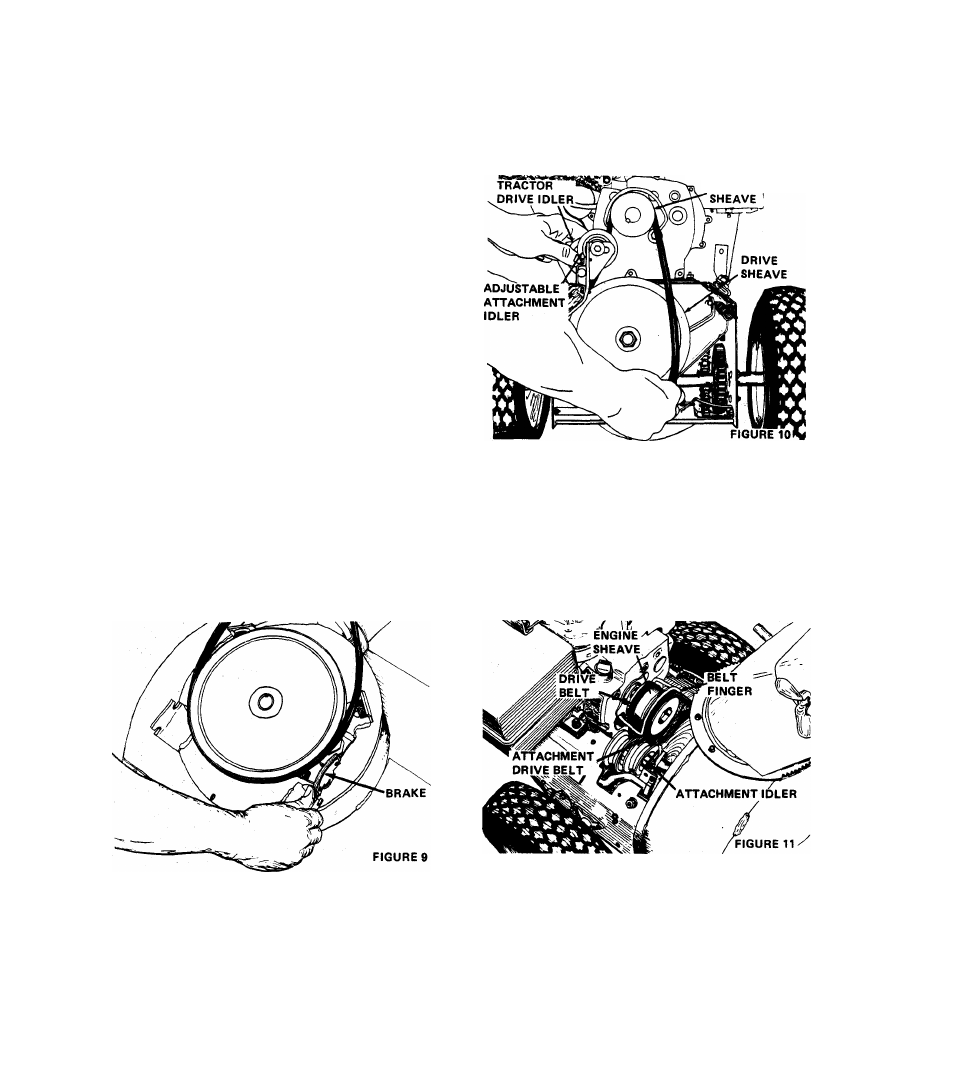

REPLACEMENT OF THE ATTACHMENT DRIVE BELT

The sno-thro attachment drive belt is on the sheave on the

blower housing. To replace this belt, hold the impeller brake

away from the belt and slip the belt from the sheave. See

Figure 9.

Replace the belt by slipping it into position on the sheave;

positioning the brake shoe on the belt.

REPLACEMENT OF TRACTOR DRIVE BELT (See Figure 10.)

The drive belt is held in place on the sheaves by an idler

pulley. To free the belt, the idler can be pulled from the

belt and the belt removed from the sheave. Activate clutch to

gain clearance. It may be necessary to pull back blower idler

arm clevis pin for additional clearance.

ENGINE

To replace the belts, position on the engine sheave first,

then on the drive sheave. .Position the idler carefully on the

belt.

With the belt in position and the idler in place, check the

belt alignment. The engine sheave and the tractor sheave must

align

with

one

another

WITH

THE

TRACTOR

CLUTCH

ENGAGED. If the sheaves are not properly aligned, loosen the

setscrews on the engine sheave and align the sheaves. Re-tighten

the setscrews. Recheck the belt alignment WITH THE CLUTCH

ENGAGED.

REPLACEMENT OF BLOWER HOUSING (See Figure 11.)

Position the blower housing on the rod in the tractor frame

and secure as follows:

1.

Tip the blower and tractor together. Hold the attachment

drive belt up as the units are tipped together. Secure with

two cap screws into the frame. As the cap screws are

tightened, hold up on the handlebars to be sure the two

units are secured together.

- 6