Ariens Sno-Thros 924000 Series User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TO TRANSPORT:

Move speed selector to desired speed.

Press down on handle bars to raise front of Sno-Thro

slightly off the ground.

Depress wheel drive clutch lever to transport unit.

TO OPERATE:

Move deflector to desirwJ height.

Turn hand crank

direct discharge chute.

Depress attachment clutch (£) to engaged position.

Move speed selector to desired speed.

Move throttle (T) to desired speed.

Depress the wheel drive clutch lever to move tractor.

Speed of the machine is controlled by the throttle and

speed selector.

TOSTOP:

Release wheel drive clutch lever Qj Depress attachment

clutch lever ^ to allow the Sno-Thro to run for a short

time to throw out slush and water and prevent freezing the

impeller fan.

Turn key(^ to "off" position to stop.

5 and 7 HP Models: Move throttle to "FAST" position after

engine has stopped.

8 and 10 HP Models: Move throttle to "SLOW" position

after engine has stopped.

NOTE: This Sno-Thro is equipped with a mechanics/ inter-

iock between wheel drive dutch and attachment dutch levers.

When both dutch levers are engaged the mechanical interlock

mil engage and the attachment dutch will remain angled as

long as the wheel drive dutch lever is not released. This frees

the right hand to operate other controls. Once the mechanics/

interlock

is

engaged,

both the wheel drive

and attachment

clutch levers must be released to disengage the attachment

drive.

Ariens Company recommencte that you have adjustments

made by your local Ariens dealer. He has the tools and know

how to properly perform these maintenance adjustments

which may be required to Heap the Sno-Thro operating at

peak efficiency. The Sno-Thro is equipped with the finest

quality engine obtainable. However, should servicing be

required, it can be obtained from an Ariens dealer or an

authorized engine manufacturer's service station. Should you

decide to make adjustments on your Sno-Thro yourself,

Ariens recommends that you call your dealer for the answers

to any questions that might arise in performing this work.

SHEAR BOLT REPLACEMENT

—_

Occasionally a small object may enter the collector and jam

the rakes. When this occurs, the shear bolts securing the rakes

to the shaft will break and allow the rake to turn freely on the

shaft preventing damage to the gear drive. When this happens,

turn off the engine, remove wire from spark plug, remove the

broken shear bolt and replace with a new ARIENS shear bolt.

Use of any other type of shear bolt may result in severe

damage to the machine. USE ONLY ARIENS SHEAR BOLTS

FOR REPLACEMENT.

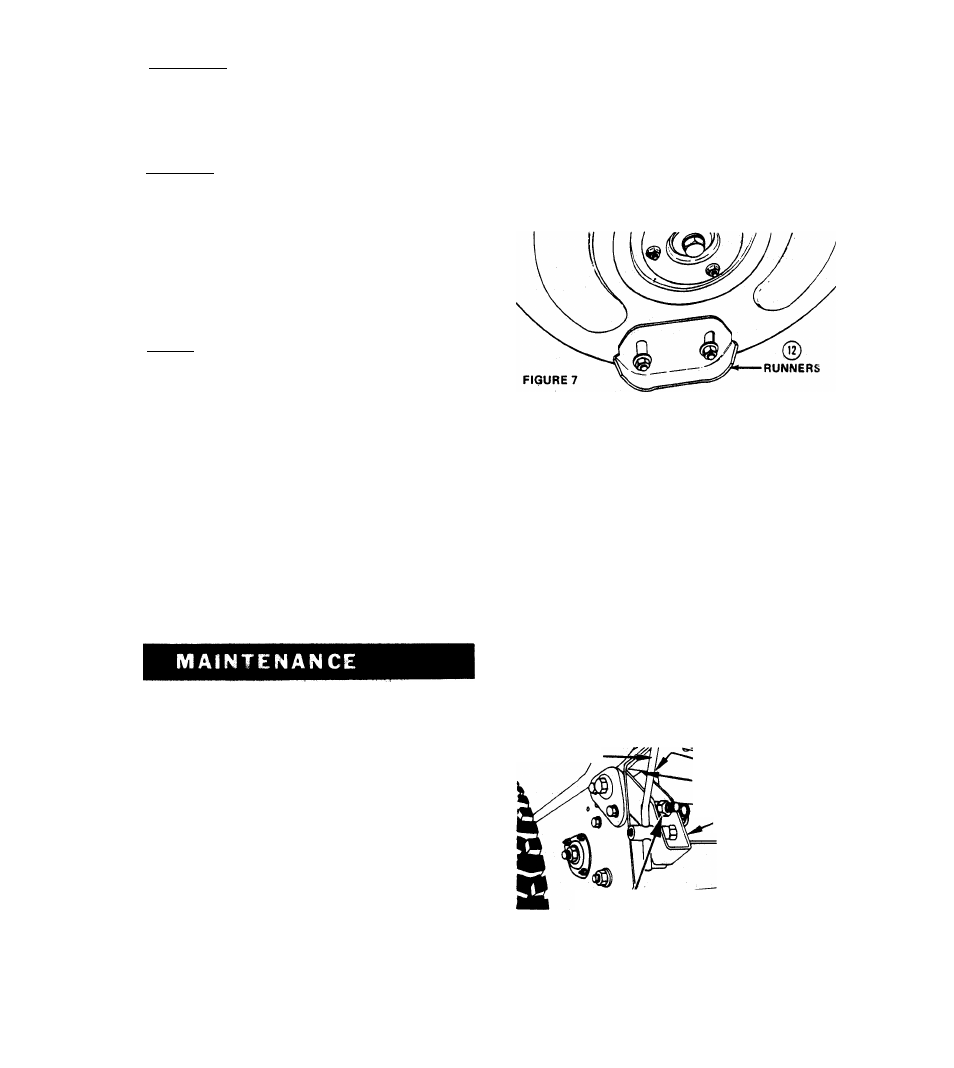

RUNNERS AND SCRAPER BLADE

The runners on each side of the blower housing, and the

scraper blade, along the back of the blower housing, are all ad

justable to suit conditions. Raising or lowering the runners

controls the distance the scraper blade is held above the sur

face being cleared. Runners are adjusted by loosening the two

nuts securing each runner. Move the runner to the desired

position and retighten the nuts. Be sure to adjust both runners

to the same height to keep blower housing level. Uneven

runners make the machine difficult to steer and will result in

an uneven clearing job.

Adjustment of the runners is critical to good cleaning. If the

machine is to be used on a gravel surface lower the runners

so the. blower will not pick up gravel then after the remaining

snow is packed down, the runners may be raised for close

scraping. On smooth concrete or blacktopped surfaces, the

runners may be raised so the scraper blade rests on the sur

face and scrapes clean.

The scraper is adjustable so it may be lowered to compensate

for wear. If the blade is allowed to wear down too far the

blower housing may be damaged.

ATTACHMENT CLUTCH ADJUSTMENT

The Attachment Clutch is adjusted by connecting the chain

to the spring just below the clutch handle. Connect the spnnii

to a chain link so the chain is snug but so the idler drops away

from the belt with the handle all ^e way up.

WHEEL DRIVE CLUTCH ADJUSTMENT

A drive disc adjustment is provided to compensate for wear

on the friction wheel. If slippage occurs when the wheel

drive clutch it engaged, tighten the drive disc adjustment. This

adjustment is accessibie without removing the bottom cover.

See Figure 8.

CLUTCH ROD

TOP OF SLOT

1/16" CLEARANCE

CLUTCH LEVER

ADJUSTMENT NUT

FIGURE 8

Adjust as follows: Place speed selector between first and

reverse. Tip machine forward on blower housing. Tighten

the adjustment nut while turning the wheels until the wheels

begin to bind. Back off 3 turns. Wheels should then turn

easily.