Deflector, Chute crank, Tire pressure – Ariens Sno-Thros 924000 Series User Manual

Page 16: Mechanical interlock, Runners- on model 924052 only, Belt adjustment, Engine, Drive chain adjustment, Long bolt runner

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

8. DISCHARGE CHUTE (MODEL 9240S2 ONLY)

13. BLOWER GEAR CASE

The discharge chute is shipped with the four mounting clips

attached to the chute. Remove the clips and hardware. Po

sition the discharge chute on the blower housing. Secure with

the clips and hardware. Be sure the chute rotates freely.

On 32" Models 924052, and 824008. Check the oil level in the

auger gear case. Oil level must be even with the oil filler hole.

Fill with Ariens Special L-2 Gear Lubricant. Replace the filler

plug.

9. DEFLECTOR

The deflector is installed on the discharge chute but must be

raised into operating position. Remove the carriage bolt and

wing nut. Rotate delfector up into operating position. Reinstall

the carriage bolt and wing nut.

On 24" Models 924046, 924048, 924050, 824006 and 824007.

The blower gear case if factory lubricated and should require

no lubrication by the dealer. Full instructions for checking are

given in the LUBRICATION section of the manual.

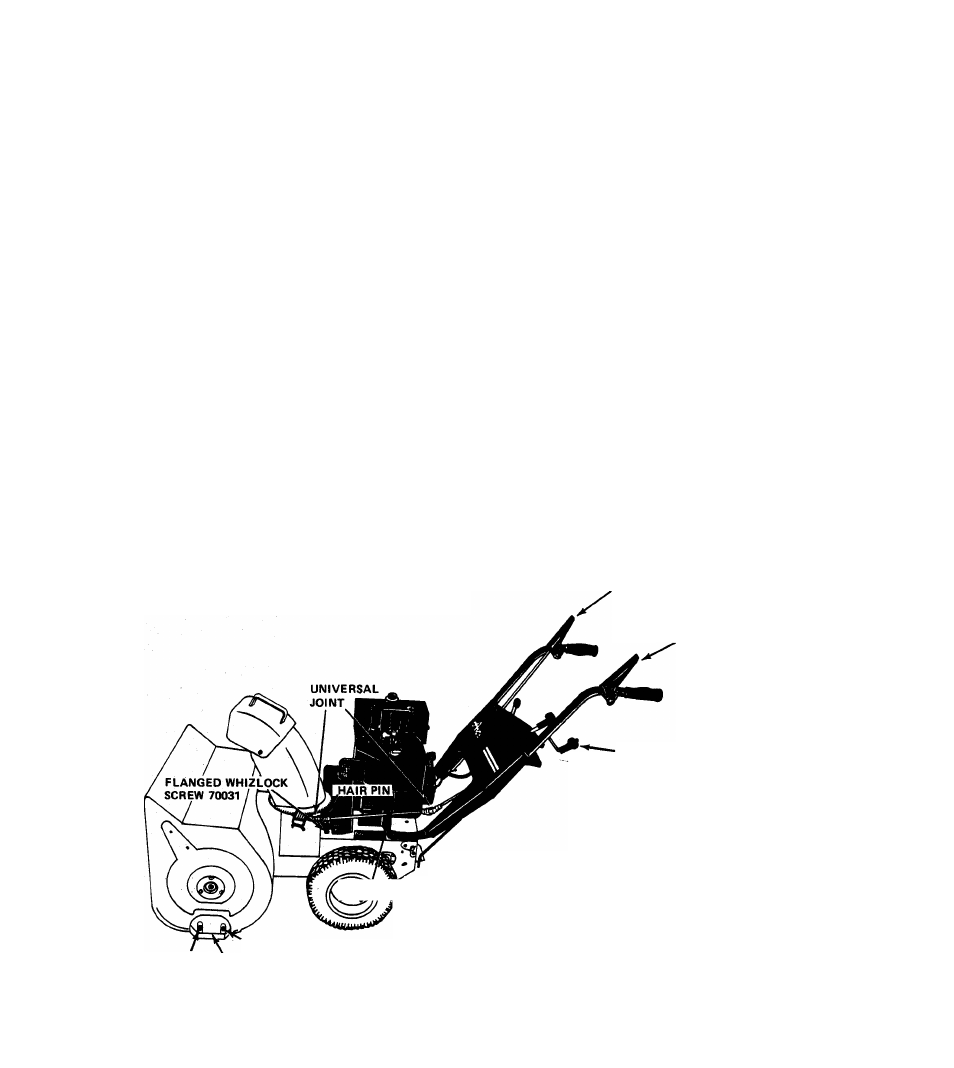

10. CHUTE CRANK

14.TIRE PRESSURE

The chute crank is packed separately in the carton. The inter

mediate shaft, universal joints and chute crank bracket are in

place on the machine. The chute crank bracket should be in

stalled on the rear, left hand stud at the time the handlebars

are installed. Insert the chute crank down into the hole in the

handlebar panel and connect to the universal joint on the

intermediate shaft with the hairpin cotter provided. On all

models, after completing the chute crank connection, check

the alignment of worm and chute by rotating the discahrge

chute through its full travel. Chute should rotate easily, if

not, reposition worm as required.

Tires have been over inflated for shipping purposes. For

operation, reduce tire pressure to 12 to 20 PSI. If tire chains

are used, a pressure of 20 PSI is recommended for proper

operation.

15.MECHANICAL INTERLOCK

Check for proper operation of mechanical interlock. Adjust

slider hardware if necessary to assure free operation. See page

5 for proper operation of mechanical interlock.

11. RUNNERS- ON MODEL 924052 ONLY

Install runners on each side of the blower housing. Use

longer carriage bolts (62013) in the rear holes, shorten

carriage bolts (6201.0) in the front holes. Use a washer

(64002) and locknut (65039) on each bolt outside thé

housing. Adjust the runners to equal height on each side. See

paragraph on page 5 for proper adjustment.

16.

BELT ADJUSTMENT

Check the position of the belt fingers on the engine sheave

and the alignment of the sheaves. Adjust as shown in Figure

10 and as described in REPLACEMENT OF TRACTOR

DRIVE BELT on page 6.

12.

ENGINE

Before starting the engine, fill the crankcase with Ariens Sno-

17.

DRIVE CHAIN ADJUSTMENT

If Models 924050 or 924052 Sno-Thro are difficult to push

because of tight or interferring drive chains, re-adjust as des

cribed in DRIVE CHAIN ADJUSTMENT on Page 7.

Thro oil 5W-20 for snow blower operation below 40 degrees

F. Use Ariens Gard-N-Yard oil 10W-30 for operation at

temperatures above 40 degrees F.

ATTACHMENT CLUTCH

TRACTOR CLUTCH

CHUTE CONTROL CRANK

•(■CHUTE CRANK BRACKET

^ yi I

DEALER

MUST

MAKE

SURE

ALL

SAFETY

DEVICES

AND

GUARDS

ARE

IN

POSITION

AND

OPERATING

PROPERLY.

DEALER

MUST

INSTRUCT

THE

CUSTOMER

ON

SAFETY

PRECAUTIONS,

OPERATION,

CARE

AND

MAINTENANCE.

FILL

OUT

WARRANTY

REGISTRA

TION AND MAIL TO ARIENS COMPANY.

SHORT BOLT

LONG BOLT

RUNNER

FIGURE 18

- 1 7 -