Roll hemming – SINGER WSL7234 User Manual

Page 19

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

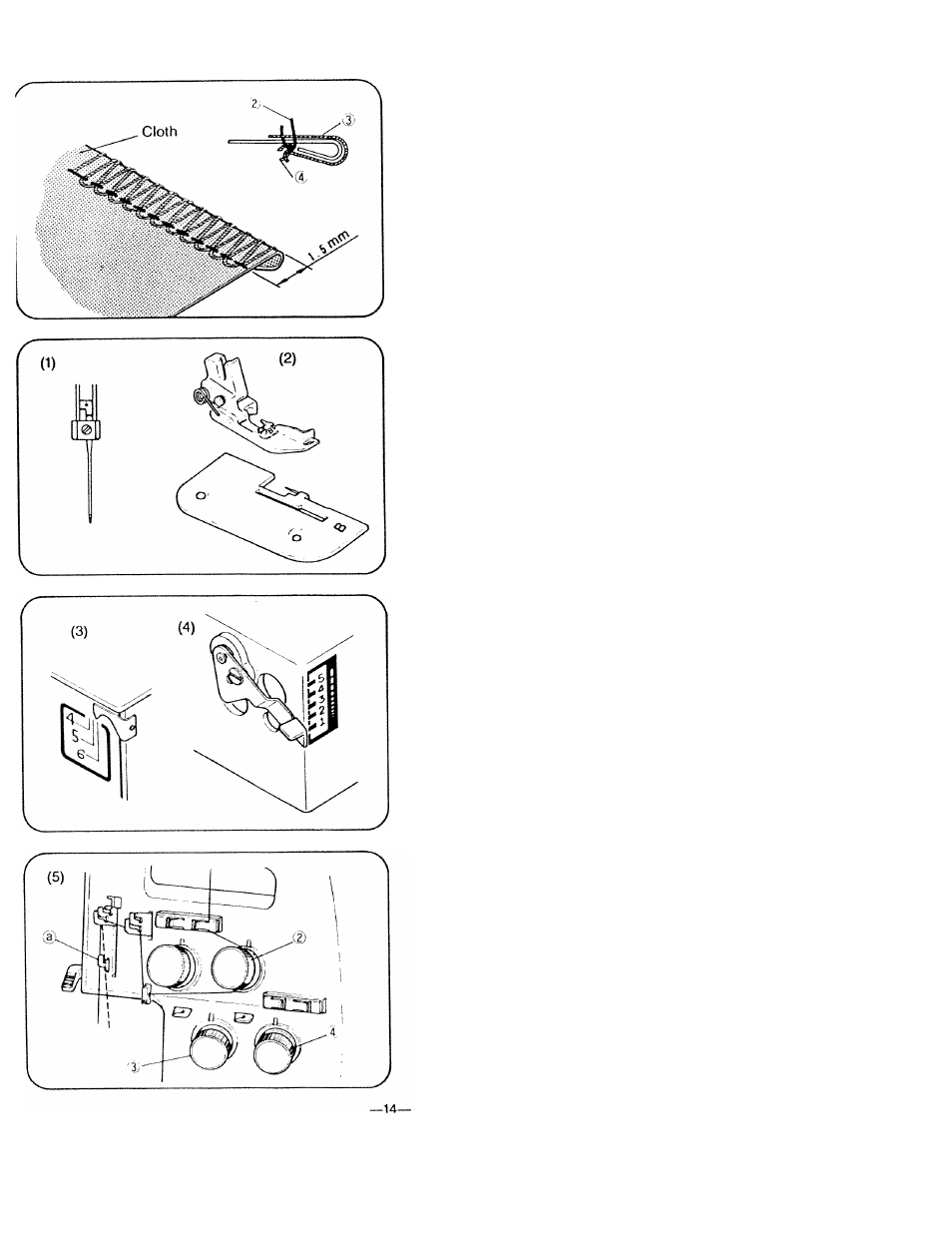

5. ROLL HEMMING

Roll hemming is achieved by adjusting the thread

tensions so that the fabric is overlocked, and

folded under to 1.5 mm in width.

It is ideal for use with thin materials.

(1) Remove the left needle. (Sew only with the

right needle)

(2) Change the presser foot and the needle plate

for roll hemming.

For roll hemming sewing, use the presser foot

marked “B” and the needle plate "B”. (The presser

foot "A” and the needle plate “A” are for normal

sewing).

(3) Set the bite width between 45and 5.5.

(4) Set the stitch length adjuster to 1.

(5) The standard thread tensions are as follows;

Dial®; Needle thread............................1 -4 tension.

Dial (3): Upper looper thread.............. 1 ~ 4 tension.

Dial®: Lower looper thread.................5~8tension

For roll hem sewing, pass the nedle thread to

the

left

side

(solid

line)

of

thread

guide @ illustrated. [For normal sewing, pass

it to the right side (dotted iine) of thread

guide @.]

At the begining of sewing, gently pull the end of

the thread chain.

For roll hem sewing, pull the material gently

towards the rear of the machine, and you’ll get

the neater stitches.