SINGER 143G2 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

To Set the Needle Bar

See that the needle Is up In the bar as far as It will

ko

.

There are two lines 3/32 Inch apart across the needle bar

about two Inches above the lower end. When the needle bar Is at

Its lowest position, the UPPER MARK should be Just visible at the

lower end of the needle bar frame.

16

£2H<)3

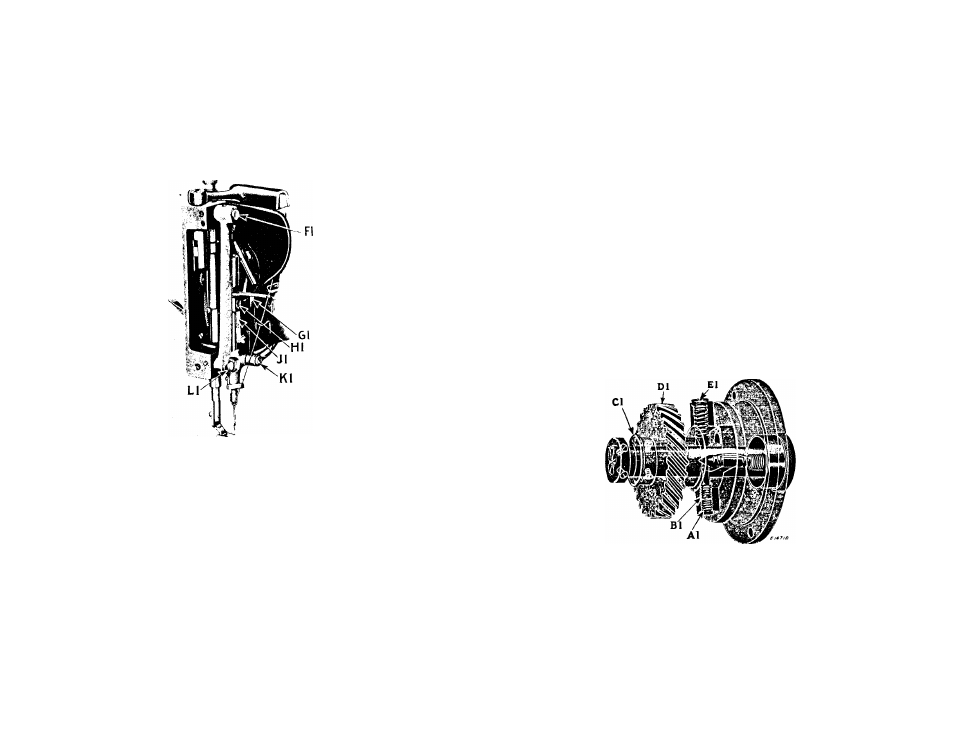

Fig. 19. Face Plate Removed

In case the needle bar Is not correctly set, loosen the

needle bar connecting stud set screw (HI,Fig.19) and move the

needle bar to the correct position, then tighten the set screw.

TO SET A NEEDLE BAR WHICH HAS NO MARK: Set the needle bar so

that when It rises 3/32 Inch from Its lowest position, the eye of

the needle will be about 1/16 Inch below the point of the hook as

the hook point enters the thread loop.

To Set and Time the Needle Bar Frame

First turn

the needle vibrator spindle head (A,Fig.2) all the

way to the right so that the needle will not vibrate when the ma

chine Is running. A straight needle should now come In the cen

tre

of

the

needle

hole

In

the

throat

plate.

If

It

does

not,

loosen

the

set

screw

which

holds

the

eccentric

stud

(Kl,Flg.l9)

ind turn the stud (KL) until It does, then tighten the set screw.

Now

turn

the

needle

vibrator

regulating

spindle

head

to

the

left

for

the

widest

throw.

Turn

the

machine

pulley

toward

you

until

the

needle

Is

at

Its

lowest

position.

As

the

needle

bar

starts

to

rise,

the

needle

bar

frame

should

start

to

move

side-

wise.

If

It

does

not,

advance

or

retard

the

vibrator

gear

pin

ion (M,Flg. 5).

To Remove the Needle Vibrator Gear Shaft

Remove

the

needle

vibrator

regulating

spindle

head

(A,Fig,2)

and the eccentric bracket cover (C,Flg.2); remove the locking and

adjusting

screws

(A1

and

Bl,Flg.20),

also

the

screw

and

spring

(El). Loosen the two set screws In the gear (Dl) and remove the

needle

vibrator

gear

shaft

collar

(L,Flg.3)

at

the

back

of

the

arm, then draw the shaft out.

When replacing these parts be careful that the large washer

(Cl,Fig.20) Is In place between the gear and arm, that the posi

tion

screws

are

set

firmly

against

the

flat

spots

on

the

shaft

and that the set screws are at the right of the position screws

when the shaft has been returned to Its place.

TO SET THE NEEDLE VIBRATOR REGULATINO SPINDLE HEAD SO

THAT A WIDER THROW THAN THE OJE DESIRED CANNOT BE MADE:

17

Fig. 20. Transparent View Showing the Needle Vibrator

Regulating Spindle Head In Front of Machine

Turn

the

spindle

head

(A,Fig.2)

to

make

the

widest

bight

possible; remove locking screw (Al,Flg.20) and turn In screw (Bl)

until

the

stitch

Is

of

the

width

desired;

then

turn

screw

(Al)

down tightly on screw (Bl) as a check. The width of stitch may

then

be

decreased

by

turning

the

regulating

spindle

head,

but

operators

cannot

make

stitches

wider

than

the

adjusting

screw

(Bl) Is set to produce.