Clean / replace spark plug, Adjusting valve clearance – Sears 580.768050 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Clean / Replace Spark Plug

Replace the spark plug yearly or every 100 hours of

operation, whichever comes first.

A

CAUTION: Disconnect spark plug wire from

spark plug and keep wire away from spark plug.

Clean area around spark plug.

Remove spark plug form the cylinder head.

Replace spark plug if the electrodes are pitted,

burned or porcelain is cracked. For replacement

use Champion RC12YC or equivalent.

Check electrode gap with wire feeler gauge and set

gap to 0.76mm {.030 inches), if necessary.

Install a correctly gapped spark plug into the

cylinder head, tighten securely.

If you think your carburetor needs adjusting, see your

nearest Sears Sen/ice Center. Engine performance

may be affected at altitudes above 5000 feet. For

operation at higher elevations, contact your nearest

Sears Service Center.

Adjusting Valve Clearance

After the first fifty (50) hours of operation, you should

adjust the valve clearance in the engine.

Important If you feel uncomfortable about doing this

procedure or you don’t have the proper tools, please

take your cleaning system In to the nearest service

center to have the valve clearance adjusted. This is a

very important step to insure the longest life for your

engine.

To adjust vah№ clearance:

• Make sure the engine is at room temperature.

• Make sure that the spark plug wire is removed from

the spark plug and out of the way.

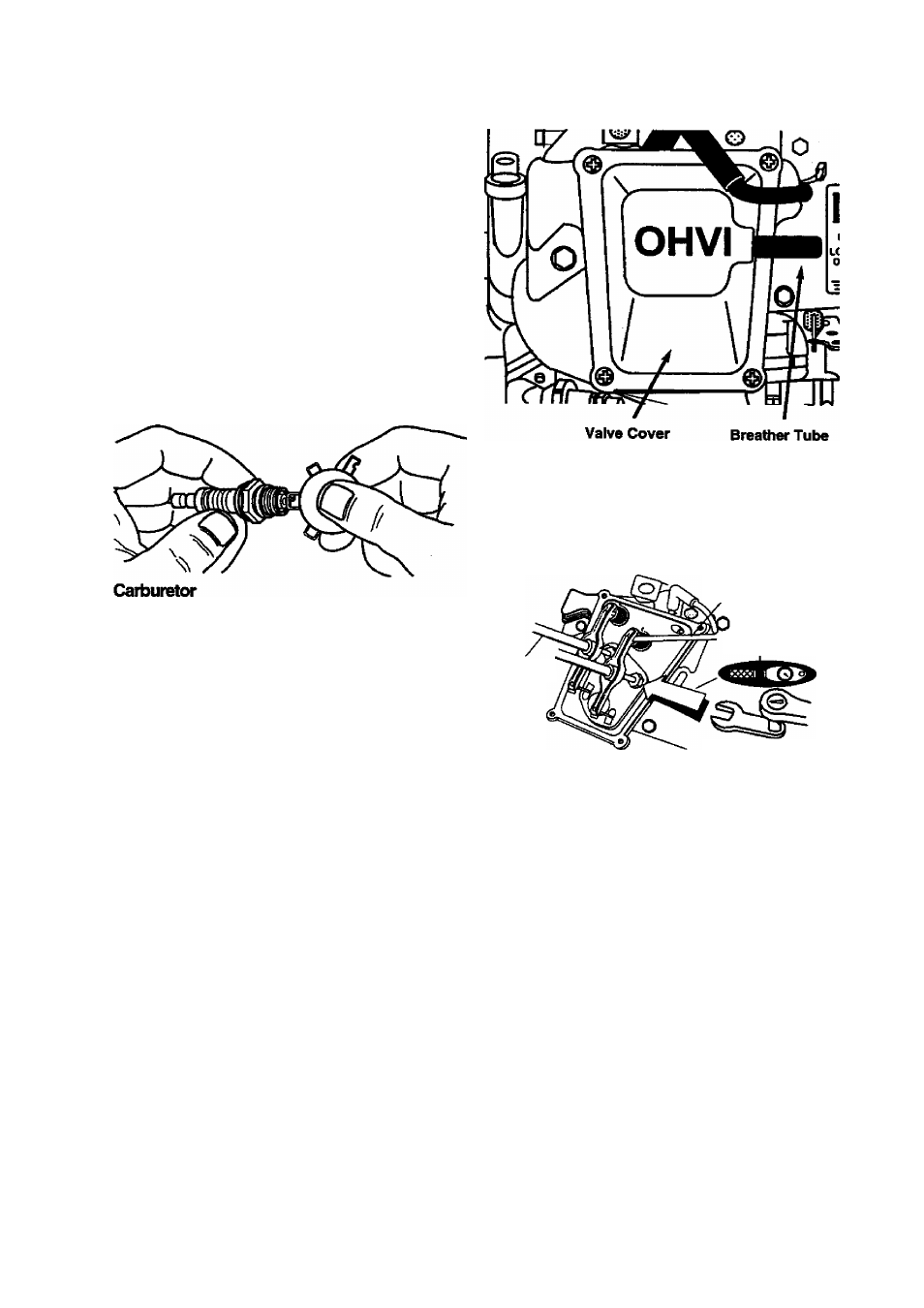

• Remove the breather tube from the valve cover.

• Remove the four screws attaching the valve cover

with a #2 or 3 Phillips screwdriver.

Make sure the piston is at Top Dead Center (TDC)

of its compression stroke (both valves closed). To

get the piston at top dead center, pull on the recoil

handle slowly watching the piston trough the spark

plug hole. As you pull on the recoil handle the ,

piston should move up and down. The piston is put

Top Dead Center when it is up as high as it can go.

FMlar Q

u

«

9

»

Tigbt«n Jam Nut to

65-85in-lba

Allan Wraneh

Looaan Jam Nut

Using a 10mm wrench, loosen the rocker arm jam

nut. Use an 8mm alien wrench to turn the pivot ball

stud white checking clearance between the rocker

arm and the valve stem with a feeler gauge.

Correct clearance is 0.002-0.004 inch (0.05

0.1mm). Note: You must hold the rocker arm jam

nut in place as you turn the pivot ball stijd.

When valve clearance is correct, hold the pivot ball

stud in place with the alien wrench and tighten the

rocker arm jam nut. Tighten the jam nut to 65-85

inch-pounds torque. After tightening the jam nut,

recheck valve clearance to make sure it did not

change.

14