Before each use, Check high pressure hose, Check ch^nical reservoirs – Sears 580.768050 User Manual

Page 11: Check gun and wand, Purge pump of air and contaminants, N(szle maint^iance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BEFORE EACH USE

• Check water inlet screen for damage.

• Check high pressure hose for leaks.

•

Check chemical tanks and filters for damage.

•

Check gun and wand assembly for leaks.

• Purge pump of air and contaminants.

• Check engine oil level.

CLEANING SYSTEM MAINTENANCE

Check and Clean Inlet Screen

Examine garden hose inlet screen. Clean if ft is

clogged or replace if It is tom.

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

DANGER; Never repair a high pressure hose.

Replace with hose that meets the minimum

pressure rating of your cleaning system

Check Ch^nical Reservoirs

Tank covers should snap cleanly onto tank. Ensure

chemical labels correctly identify tank contents.

Ensure that the System Rinse tank Is filled with clean

water. Ensure that Dial-A-Cleaner”* selector knob

rotates freely between each position. Examine the

tanks and replace if the filter is clogged

Check Gun and Wand

Examine hose connection to gun and make sure it is

secure. Test trigger by pressing it and making sure it

springs back into place when you release it. Put safety

latch in UP position and test trigger. You should not be

able to press trigger. Replace gun immediately if it

fails any of these tests.

Purge Pump of Air and Contaminants

To remove the air from the pump, follow these steps:

•

Set up the cleaning system as described in the

ASSEMBLY section and connect the water supply.

• Remove the wand extension from the gun.

•

Pull the trigger on the gun and hold until a steady

stream of water appears.

To remove the contaminants from the pump, follow

these steps:

•

Set up the cleaning system as described in the

ASSEMBLY section, and connect the water supply.

•

Remove the nozzle attachment from the gun.

• Start the engine according to instructions in

OPERATION section.

•

Pull the trigger on the gun and hold.

•

When the water supply is steady and constant,

engage the safety latch and refasten the nozzle

attachment.

N(szle Maint^iance

If the nozzle becomes restricted or clogged with

foreign materials, such as dirt, excessive pump

pressure may develop. A partially clogged nozzle can

cause a pulsing condition during use. This generally is

not a pump related problem, but rather a clogged or

partially restricted nozzle.

If the nozzle becomes clogged or partially restricted,

immediately clean the nozzle with the kit included with

your cleaning system by following these instructions:

• Shut off the engine and turn off the water supply.

■ Press trigger to relive water pressure.

•

Separate the dual lance from the gun. '

•

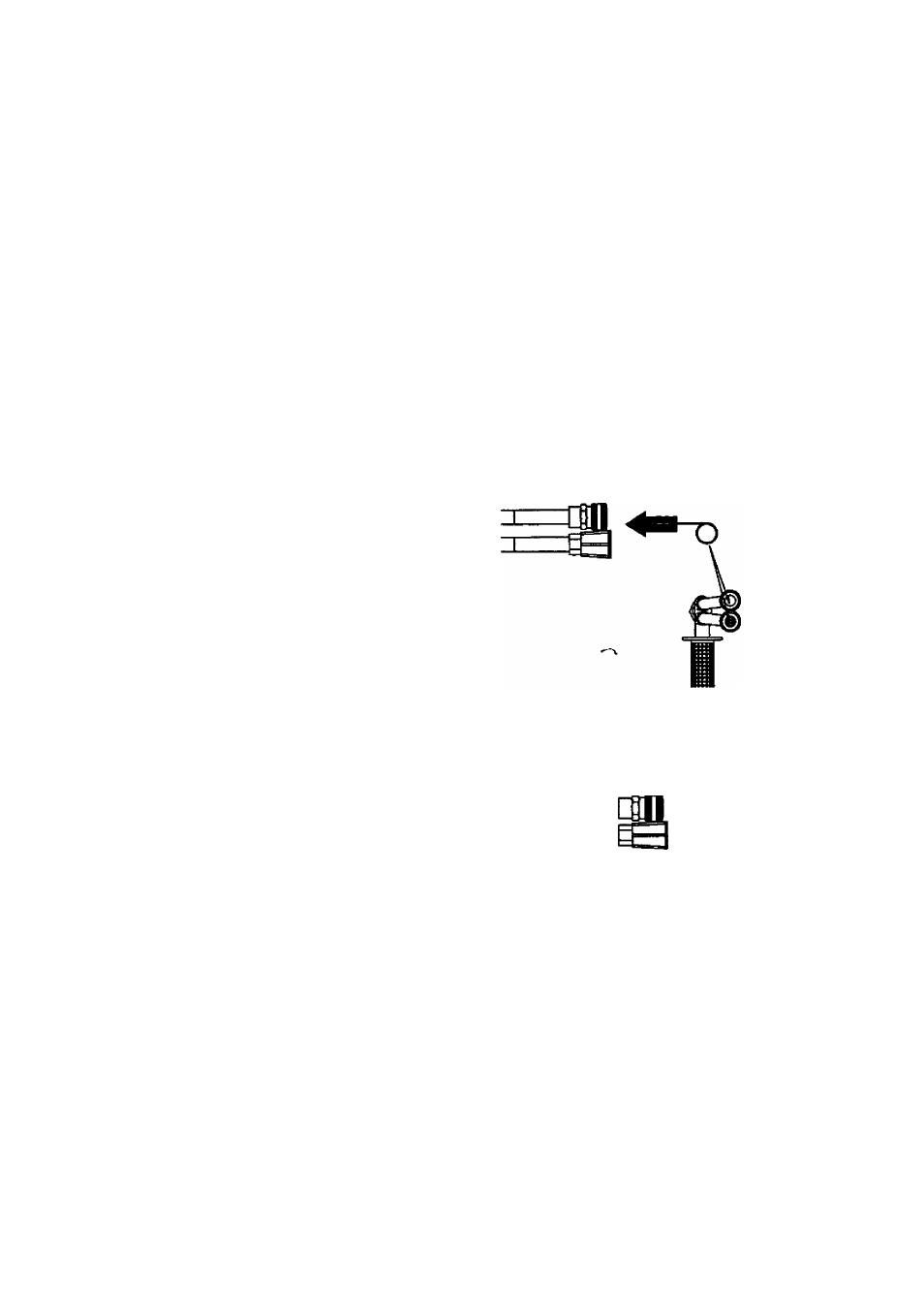

Use the wire included in the kit or a small paper

clip to free the foreign materials clogging or

restricting the nozzle.

Insert wire Into

nozzle and turn

back and fo^

to clear

obstruction.

Remove additional debris by back flushing water

supply through dual lance (Figure 2). Back flush

between 30 to 60 seconds. Back flush both lances

by turning chemical valve handle.

<^==11

Reconnect the dual lance to the spray gun.

Reconnect the water supply, turn on the water, and

start the engine.

Test the cleaning system by operating with the unit

in high and the low pressure.

11