Storage – Sears 247 886510 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

The Maintenance Check List is supplied to assist the

operator in proper maintenance of the snow thiower.

This is only a check list; instructions for adjustments

will be found in the Adjustments/Repairs section 3f this

manual.

Some adjustments will need to be made periodically

to properly maintain your snow thrower.

AH adjustments in Adjustments/Repairs section 3f this

manual should be checked at least once a season. The

following should be performed more than once each

season.

All Bolts and Nuts—

Should be checked often to make

certain they are tight, preferably after each uso.

Engine and Snow Thrower—

Lubricate as insti ucted

in the following section.

LUBRICATION

Engine Lubrication—

Check Oil Level before starting

engine and every 5 hours of operation. Oil level must

be maintained between the “Full” and “Add” marks

on dipstick. Refer to “To Service Engine” instru étions

on page 11.

Change Oil after first 2 hours of operation and every

25 hours thereafter. Change at least once a yea if the

snow thrower is not used for 25 hours.

To drain oil, position snow thrower so the oil drai ^ plug

is the lowest point on the engine. Remove oil drai i plug

and oil fill cap . See figure 23. Drain oil into a suitable

container. Oil will drain more freely when warn.

Replace oil drain plug and tighten securely. Refill

crankcase with SAE 10W30 motor oil. SAE 5W30 motor

oil may be substituted when temperature is consi stently

20°F. or lower.

Oil Cap/

Dipstick'

Drain

Plug

FIGURE 23.

NOTE: Oil level

must be between

full and add mark

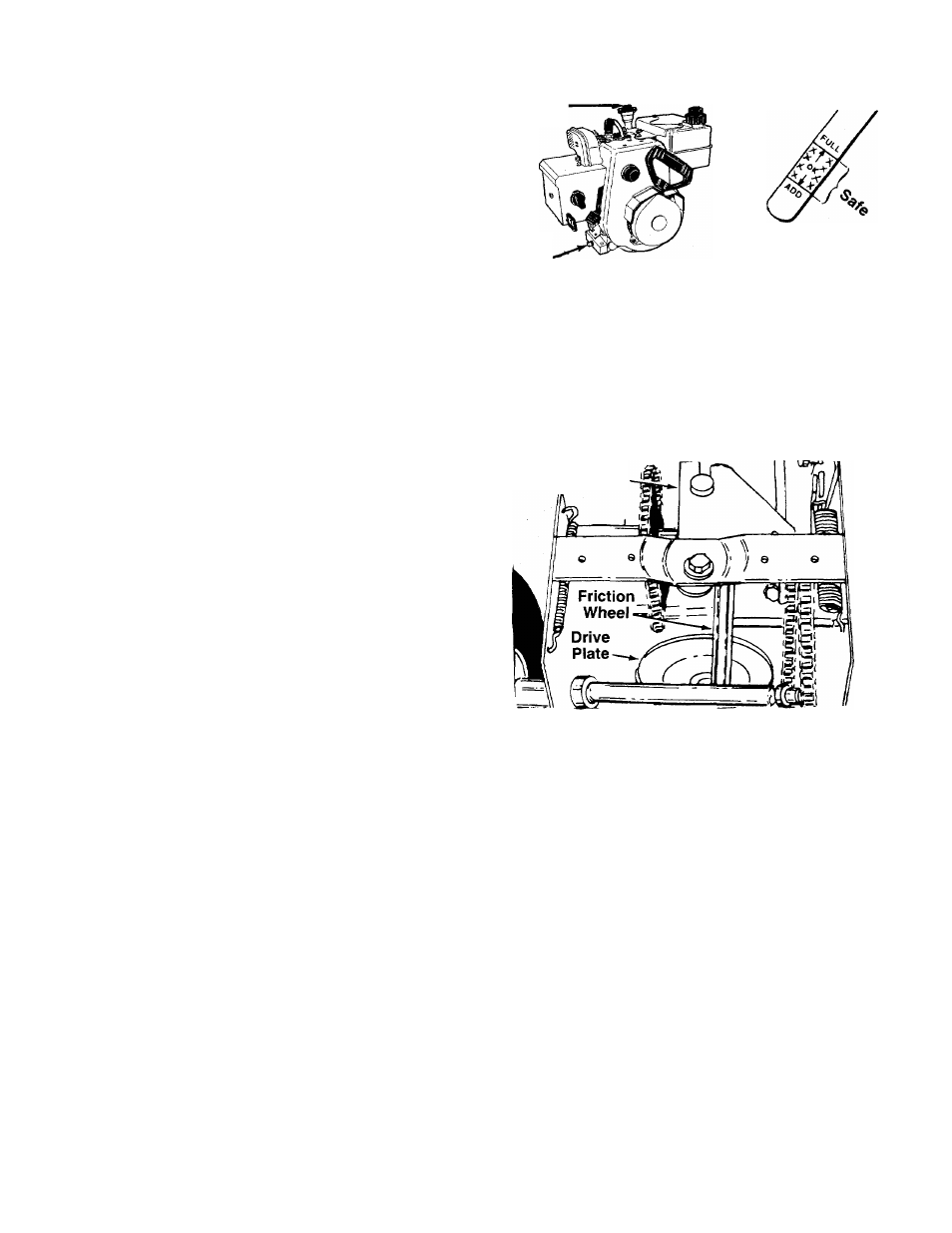

Chains and Shifting Mechanism—

Lubricate all

chains, bearings, gears and the shifting mechanism

with engine oil after every 10 hours of operation or at

least once a season. See figure 24. Avoid getting oil

on the friction wheel and drive plate.

Shifting

Mechanism

FIGURE 24.

¡STORAGE

A

WARNING

Never store engine with fuel in tank

indoors

or

in

poorly

ventilated

enclosures, where fumes may reach an

open flame, spark or pilot light such

as on a furnace, water heater, clothes

dryer, etc.

It is important to prevent gum deposits from forming

in essential fuel system parts such as the carburetor,

fuel hose or fuel tank during storage. Also, expe rience

indicates that alcohol blended fuels (called gas jhol or

using ethanol or methanol) can attract moisture which

leads to separation and formation of acids during

storage. Acidic gas can damage the fuel syster i of an

engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow

these instructions.

1. Run engine until fuel tank is empty and engine

stops due to lack of fuel.

2. Disconnect fuel line at carburetor or fuel tank. Be

careful not to damage fuel line, fittings or fuel tank.

Drain any remaining fuel from the system.

A

I WARNING

\

Drain fuel into approved container

outdoors, away from open flame.

14