Choice of blade and speed, Basic saw operations – Sears 113.244530 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CHOICE OF BLADE AND SPEED

Your

band

saw

will

cut

a

wide

variety

of

material-wood, wood like products, non-ferrous met

als (brass, aluminum, copper) and ferrous metals

(steel, iron). In order to obtain satisfactory results fol

low these general guide lines:

1. Use the correct type of blade for the material being

cut. For example if cutting ferrous metal make sure

to use a steel cutting blade.

2. Use a finer tooth blade for cutting thin workpieces

when a smoother cut is required, for hard materi

als, or when using lower speeds.

3. Use a coarser tooth blade for cutting thicker work

pieces, when making straight cuts, for medium to

soft materials or when using higher speeds.

4. Use a blade that will have at least 2 teeth in the

material at all times.

5. Use thin, narrow blades for tight radius work, and

thick, wide blades for large curves and straight

cuts.

6

. Match the approximate blade speed (FPM) to the

material being cut. See chart below;

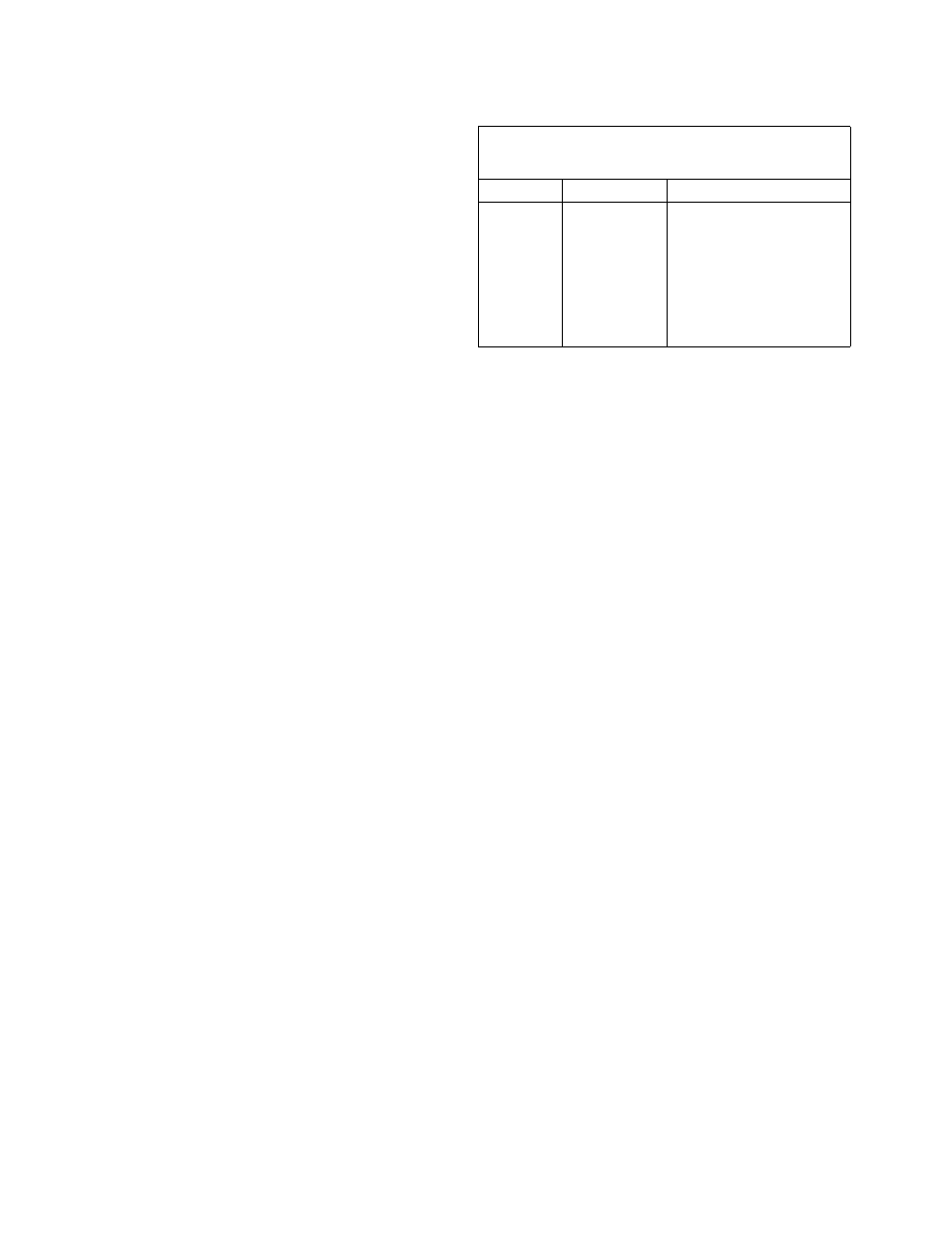

BLADE TYPE AND APPROXIMATE

SPEED FOR CUTTING

Material

Speed

Blade

Wood

Plastic

Aluminum

Brass

Copper

Steel

2460 FPM

1230 FPM

1130 FPM

840 FPM

400 FPM

300 FPM

General Purpose Blade

General Purpose Blade

Metal Cutting Blade

Metal Cutting Blade

Metal Cutting Blade

Metal Cutting Blade

CAUTION: Do not cut hardened steel.

Basic Saw Operations

BEFORE EACH USE:

Inspect your saw.

Make sure the blade guides and thrust bearings

are properly adjusted.

DISCONNECT THE SAW. To avoid injury from acci

dental starting, unplug the saw, push the knob off and

lock with a padlock before changing the setup, open

ing covers, removing guards, or blade.

CHECK FOR DAMAGED PARTS. Check for:

• alignment of moving parts,

• binding of moving parts,

• broken parts,

• stable mounting, and

• any other conditions that may affect the way the

saw works.

If any part is missing, bent, or broken in any way, or

any electrical part doesn’t work properly, turn the saw

off and unplug the saw. REPLACE damaged, miss

ing, or failed parts before using the saw again.

MAINTAIN TOOLS WITH CARE. Keep the saw clean

for best and safest performance.

REMOVE

ADJUSTING

KEYS

AND

WRENCHES

from tool before turning it on.

To avoid injury from jams, slips or thrown pieces:

• Choose the right size and style blade for the

material and the type of cutting you plan to do.

•

USE ONLY RECOMMENDED ACCESSORIES.

(See page 19). Consult this owner’s manual for

recommended accessories. Follow the instruc

tions that come with the accessories. The use of

improper accessories may cause risk of injury to

persons.

•

• Make sure the blade teeth point downward,

toward the table.

• Make sure the blade tension is properly

adjusted.

• Make sure the table lock knob is tight and no parts

have excessive play.

• To avoid accidental blade contact, minimize blade

breakage and provide maximum blade support,

always adjust the upper blade guide and blade

guard to just clear the workpiece.

• KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents. Floor must not be slip

pery.

To avoid burns or other fire damage, never use the saw

near flammable liquids, vapors or gases.

Plan ahead to protect your eyes, hands,

face, ears.

KNOW YOUR SAW. Read and understand the owner’s

manual and labels affixed to the tool. Learn its applica

tion and limitations as well as the specific potential haz

ards peculiar to this tool.

To avoid injury from accidental contact with moving

parts, don’t do layout, assembly, or setup work on the

saw while any parts are moving.

AVOID ACCIDENTAL STARTING. Make sure switch is

“OFF” before plugging saw into a power outlet.

Plan your work.

• USE THE RIGHT TOOL. Don’t force tool or attach

ment to do a job it was not designed to do.

• Use this band saw to cut only wood, wood like

products, plastics, non-ferrous and ferrous metals

(ferrous metals 1/16 inch thick or less).

16