Start-up – Carrier 19DG User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

8. Wi’th“OIL PUMP button depressed, alternately

stop and restart chilled water and condenser

water pumps. SAFETY CIRCUIT and LOAD

RECYCLE lights should go out as each pump

stops. (Continuous operation of oil pump is

unnecessary during these checks.)

CONTROL LIGHTS

□

OFF

■ ON

□

□

□

■

■

□

□

□

a

■

■

n

■

■

■

n

□

■

■

■

□

□

□

■

□

■

9

10

II

12

13

14

ON-STOP

START

OIL PUMP

POWER

SAFETY CIRCUIT

LOAD RECYCLE

PROGRAM TIMER

9. Shut off water pumps. Release OIL PUMP

button. Press ON-STOP button (hght goes

out). Replace tagged wire on terminal

10. Press ON-STOP button (hght goes on).

11. Press machine START button (motor leads

disconnected).

12. Oil pump starts within 30 seconds.

13. Compressor motor start contacts will close 30

seconds later. Starter will transfer to run

condition 30 to 60 seconds after starter is

energized.

14. Open oil pump main disconnect. Starter must

de-energize. OIL PUMP hght will remain on for

approximately 30 seconds.

15. OIL PUMP light goes out.

16. Close oil pump disconnect. In approximately

15 minutes, the program timer will complete

the antirecycle portion of its cycle and the

machine is ready to restart.

17. Remove all power and reconnect motor leads.

Restore power.

Purge

— Place the purge operating valves (Fig. 1) in

“Normal-Automatic” position as indicated in oper

ation no. 1 on the purge valve operation plate

(item 17, Fig. 1). Operate the purge pump momen

tarily by placing the purge switch in “Manual”

position; then place purge switch in “Auto.”

position.

START-UP

Preliminary Checks

1. Power on to main circuit breaker, control

circuit, water pumps and tower fan.

2. Cooling tower water level.

3. Oil reservoir level.

4. Oil reservoir temperature 145 F or warmer.

5. Oil cooler plug cock (Fig. 1) cracked open, and

any other valves in oil cooler line fully open.

6. Refrigerant at proper level.

7. Valves in chilled water and condenser water

circuits open and water circulating properly. Do

not permit water above 100 F to flow thru

cooler.

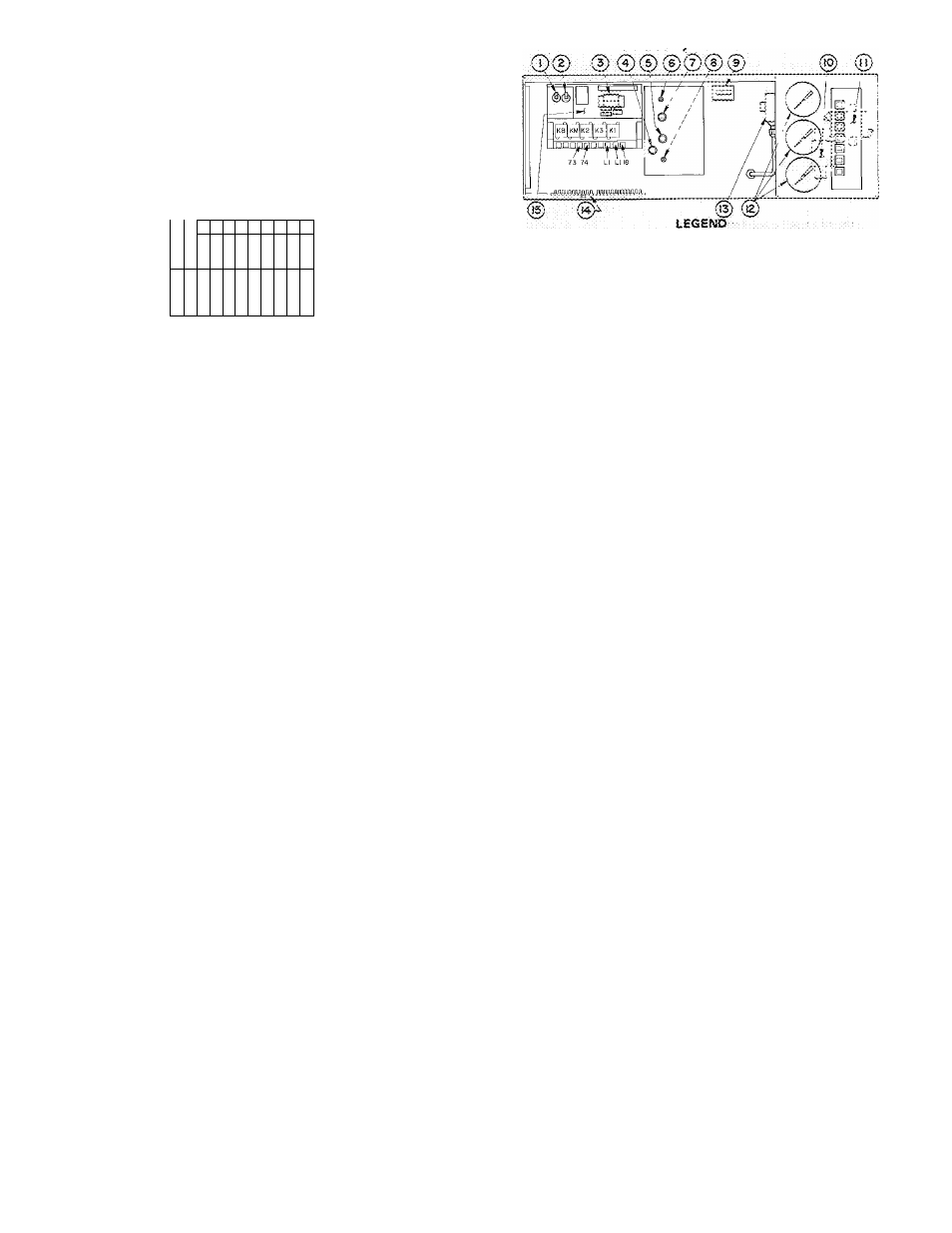

1 — Searing High-Temperature C'Jtout iXtenua! Reset)

2 — Motor tiigh-Temperafure Cutout (Mapua! Reset)

3 — Prograrr. Timet

4— Capacity Comrot Switch

5 — &tectric3i Demarto Acfjusimeot

6 —Throttfe Rarige Aojustmem

7—Thermostat iChilieci’Water)

5— Motor Current Calibration

9-eiaP38d-Time(ncl!cator

TO— Low Oil Pressure Cutout

1 — Vane-t^iose Oii Pressure Switch

12 — Pressure G ages

■J3 — Conclertser HighPressurs Cutout (Manual Reset)

■J4. _ Terminal Strip (PielcJ Connections)

15 — Retey Ntocfule

Fig. 3— Control Center

COMPRESSOR ROTATION Set capacity con

trol switch (Fig. 3) to “Hold”. Press machine

ON-STOP and START buttons. As soon as motor

starts to turn, press machine ON-STOP button.

Check motor rotation thru sight glass in motor end

bell (Fig. 1). Motor rotation must be clockwise

when viewed from motor end. If not, reverse any 2

of 3 power leads coming into motor starter and

recheck rotation.

COMPRESSOR OPERATION ~ Press machine

ON-STOP and START buttons and let compressor

come up to speed. Press machine ON-STOP button

and listen for any unusual sounds coming from the

compressor and transmission housing as the com

pressor coasts to a stop.

The program timer prevents rapid recycling of

the compressor and allows restart 15 minutes after

stop.

Checking Safety Control Settings

While performing these checks, carefully

monitor chilled water temperature to prevent

freeze-up. Protection by safety cotrols cannot

be assumed until all settings have been con- .

firmed as follows.

Open main disconnect (all power off to starter

and controls). Set capacity control switch to

“Hold”. Place a clamp-on ammeter on one of the 3

starter leads. Install jumpers between 40 and [^,

and between (l^ and jj_. Close disconnect(s);

start compressor and check oil pressure and tem

perature (Pig. 1). With compressor running,

manually operate the guide vanes with the capacity

control switch. Do not exceed 100% of full load

amperage.

1. Check controls 1,2 and 3 as indicated in T|^ 2.

2.

Stop machine; open disconnect(s); remove

jumpers and check controls 4, 5 and 6 as

indicated in Table 2.