Carrier 19DG User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Oil Heater

— Energize’ the oil heater to minimize

absorption of refrigerant by the oil. An indicator

light (Fig. 1) goes on when the oil heater is

energized. Set the oil heater thermostat to main

tain a minimum oil reservoir temperature of 145 F

at shutdown.

Charging Refrigerant

— Proceed as follows.

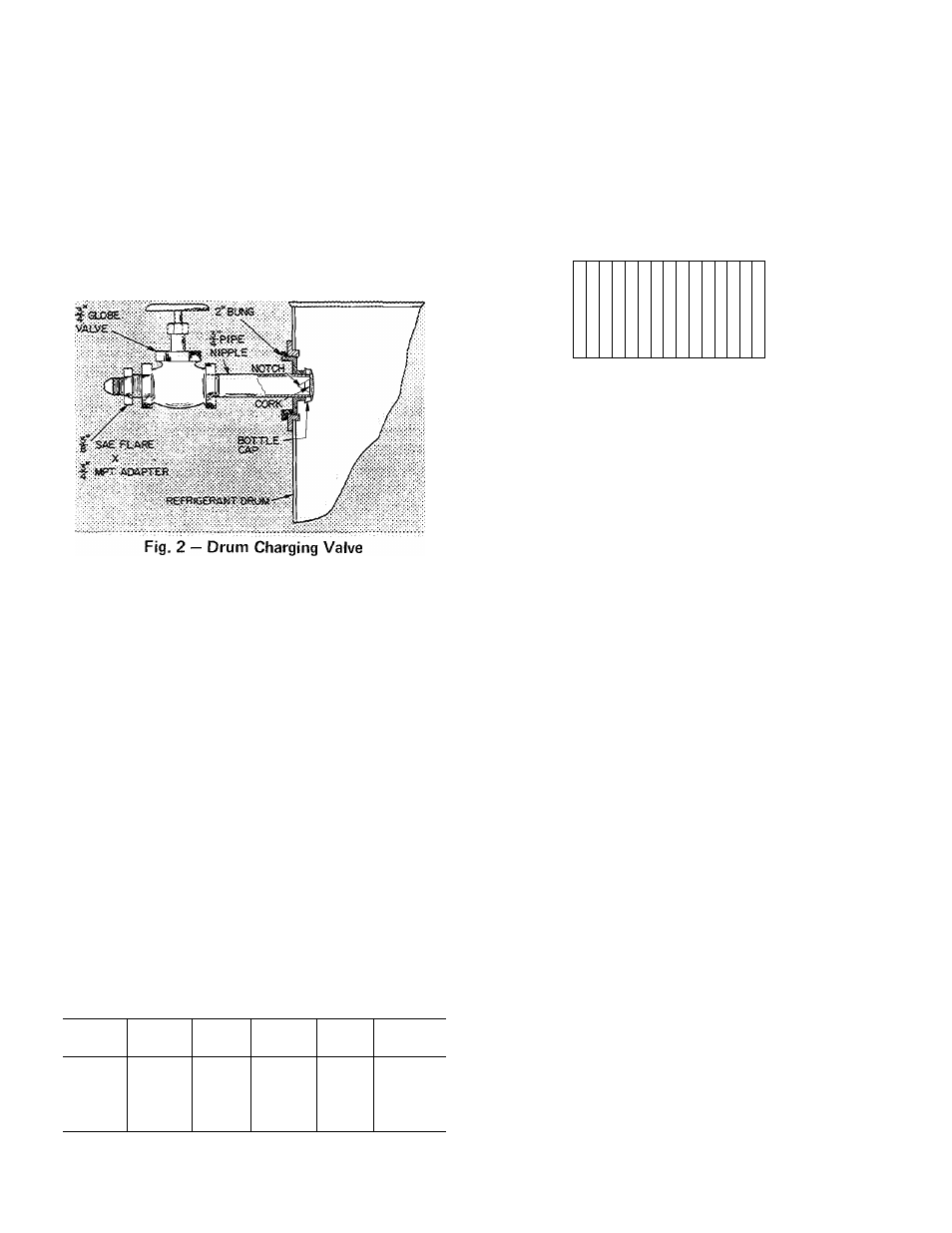

1. Install a charging valve on the 3/4-m. drum

opening as shown in Fig. 2. When the 3/4-in.

pipe nipple is screwed in, the nipple forces the

bottle cap off its seat.

2. Connect a short piece of plastic hose or copper

tubing from drum valve to the cooler charging

valve located beside the float chamber (Fig. 1).

3.

Circulate chilled water during the charging

process.

4.

At a vacuum of IS in. Hg or greater, liquid

Refrigerant 1 i will flash mto gas and may

cause tube freeze-ap. If machine vacuum is

18 in. Hg or greater, keep refrigerant drum

upright, open valves and admut refrigerant to

cooler as a gas until machine vacuum is ies.s =

than 18 m. Kg.

5. The refrigerant supplied with the machine is in

excess of that required for initial charging.

Charge only that amount shown in Table 1 The

machine under vacuum will draw refrigerant

from the drum.

6. After the machine has been started, it may be

necessary to adjust the refrigerant charge for

optimum

machine

performance.

Refer

to

Trimming Refrigerant Charge (page 7) for full

load adjustment.

Table 1 — Charging Quantity

SIZE*

WEIGHT

(lb R-11)

SIZE*

WEIGHT

(lb R-11)

SIZE*

WEIGHT

(lb R-11)

19DG11

400

19DG21

525

19DG33

760

19DG13

400

19DG23

550

19DG35

800

19DG15

425

19DG25

575

19DG36

925

19DG17

450

19DG27

575

19DG37

985

19DG20

525

19DG31

725

19DG39

960

Check Operation of Safety Controls

— As checks

are made, the control panel lights should appear as

indicated.

1. Open main disconnect (all power off to starter

and controls). Then disconnect main motor

leads in starter.

2. Provide control circuit power.

CONTROL LIGHTS

□ OFF

□

□

■

□

■

■

■

■

□

□

□

□

□

□

□

□

□

□

□

a

n

■

□

■

□

■

■

■

■

■

■

■

□

□

■

□

□

■

□

□

□

□

■

□

□

■

□

□

□

□

□

□

□

□

□

□

1

2

3

4

5

6

7

8

ON-STOP

START

OIL PUMP

POWER

SAFETY CIRCUIT

LOAD RECYCLE

PROGRAM TIMER

*Unishe(i Size

• Sec lower right corner of machine identification

plate (Fig 1)

3. Press ON-STOP button (light goes on). If

SAFETY CIRCUIT light does not go on, check

resets on condenser high-pressure safety, low-

refrigerant safety, bearing and motor high-

temperature circuit breakers and compressor

overloads in starter. Check 3-amp fuse in

control center.

If SAFETY CIRCUIT light goes on but LOAD

RECYCLE light stays off, check the chilled

water recycle switch (Auto.-Reset).

If both lights go on, manually trip and reset

motor and bearing high-temperature circuit

breakers, compressor motor overloads in

starter, low-refrigerant temperature cutout and

high-condenser cutout to be sure they cut off

the safety light. Tripping the chilled water

recycle switch will cut off the LOAD RE

CYCLE light only.

4.

Press ON-STOP button (light goes out).

Remove and tag gray striped wire running

between terminal [1^ and Vl_ in control

center.

5.

Start chilled water and condenser water

pumps. Press ON-STOP button (light goes on).

6. Press OIL PUMP button for several seconds.

Pump should raise oil pressure to 20-25 psi

differential between pump discharge gage on

control panel and oil reservoir gage. SAFETY

CIRCUIT and LOAD RECYCLE lights should

go on.

7. Release OIL PUMP button. SAFETY CIR

CUIT and LOAD RECYCLE lights should go

out.