Start-up, Service, Refrigerant charging – Carrier 50MH User Manual

Page 5: Lubrication, Condenser, Evaporator, Return air filter

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

#

START-UP

Adjust remote control center as follows:

1. Set selector switch at “Off.”

2. Fan switch at “Auto.” or “Fan.”

3. Turn on main disconnect switch(es) to unit.

4. Set thermostat dial to the desired temperature.

5. Selector switch at “Heat” or “Cool.”

Electric Resistance Heater Operation

— When

thermostat calls for heating, evaporator fan and

heater no. 1 are energized immediately. Remaining

heaters are energized in 30 second intervals. When

thermostat is satisfied, the cycle reverses and

heaters are de-energized in 30-second intervals.

Evaporator fan motor shuts off with last heater.

SERVICE

Table 3 — Service Data

UNIT

50MH003

50MH004

R-22 CHG (Ib-oz)*

3-0

3-11

Refrig Control

TXV

TXV

COMPRESSOR

38GC401404

51YA400524

Type Start

CSR

CSR

Oil Recharge (oz)

45

50

EVAP FAN

Centrifugal — Direct Drive

Rpm

1075 - 950 - 850

Diam (in.)

10

10

Width (in.)

8

8

Nom Cfm

1125

1350

Norn Motor Hp

COND FAN

Propel 1er — Di rect Drive

Rpm

1050

1050

Diam (in.)

18

18

Norn Cfm

2400

2400

Norn Motor Hp

%

ke

CSR — Capacitor Start

* Factory refrigerant charge

REFRIGERANT CHARGING

Refrigerant System is factory charged. When

recharging is necessary, weigh in total charge

indicated in Table 3. Blow any refrigerant

remaining in system before recharging. Standard

1/4-in. Schraeder service connections provided on

high and low sides of refrigerant system for

evacuation and charging.

LUBRICATION

Compressor

contains factory oil charge. Replace oil

when lost. See Table 3 for oil charge. If necessary,

refer to Carrier Standard Service Techniques

Manual, Chapter 1, pg 1-21, for oil recharging

procedure. Use Carrier PP33-1, Texaco Capella B

or Suniso 3G oil.

Fan Motor Bearings

are prelubricated for three

years heavy duty or five years normal duty. When

lubrication is necessary, send motor to authorized

motor repair shop.

CONDENSER

Coil

— Lift or remove unit top cover for access to

condenser coil. Inspect coil periodically. Clean

with brush, vacuum cleaner, low-pressure water,

steam or air.

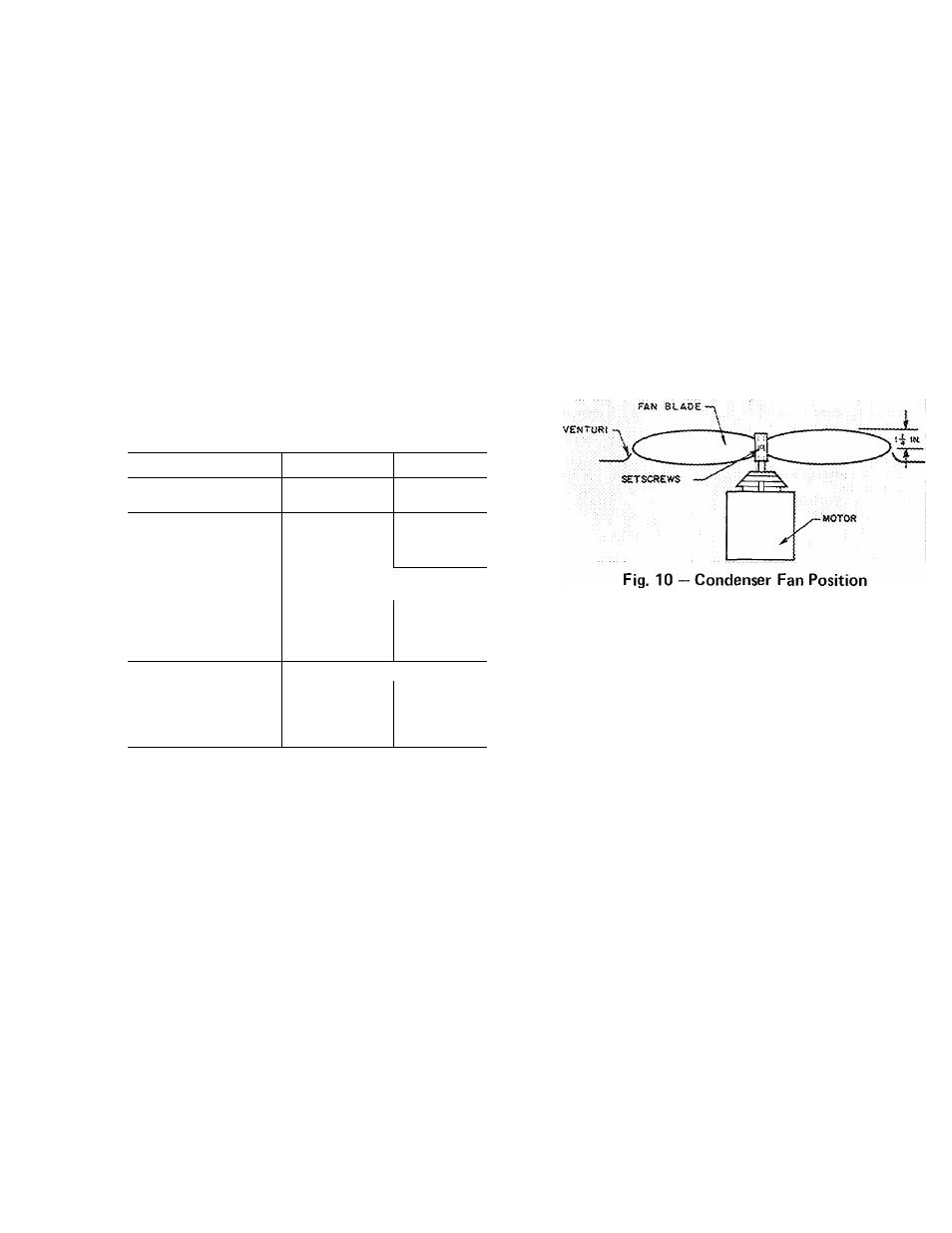

Fan Position

— Required fan position is shown in

Fig. 10. Adjust fan by loosening setscrews and

moving blades up or down.

EVAPORATOR

Coil

— Lift or remove unit top cover for access to

evaporator coil. Inspect coil periodically. Clean

with brush, vacuum cleaner or low-pressure air.

CONDENSATE DRAIN — Clean condensate drain

trap with bottle brush, then flush condensate pan

beneath evaporator coil with clean water. Ensure

water flows freely thru condensate drain.

Evaporator Fan Wheel

should be centered in fan

housing. To adjust, loosen setscrews holding fan to

rhotor shaft. Adjust fan and retighten setscrews.

EVAPORATOR PAN REMOVAL - Disconnect

fan motor wiring. Remove two fan housing sheet

metal screws shown in Pig. 6 and slide out

complete fan and motor assembly.

RETURN AIR FILTER

Clean filter a minimum of twice yearly. Flush

permanent-type filter with hot water, steam or

soak in mild solution of soap or detergent and

water. Allow filters to dry and replace. Refer to

filter manufacturer’s instructions, as required, for

other types of filters.

«