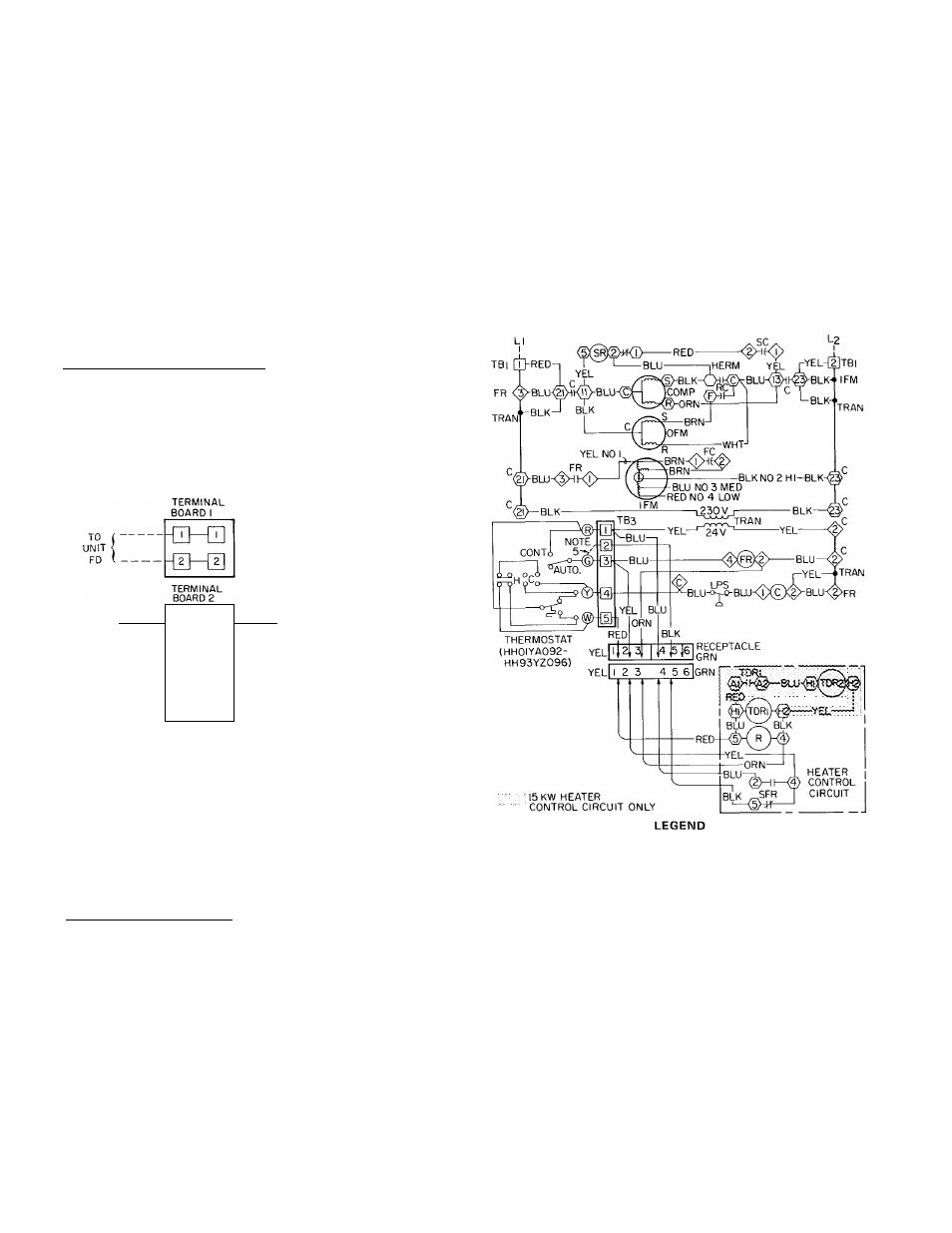

Fig. 7 — line power connections, Fig. 9 — typical system wiring diagram, 10 kw – Carrier 50MH User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

each electric resistance heater. Voltage to unit

during operation must be within ± 10% of voltage

range indicated on nameplate.

Failure due to operation of unit on improper

line voltage constitutes abuse ana is not covered

by Carrier Warranty.

LINE POWER — Bring line power leads from fused

disconnect thru hole provided (Fig. 1) into high

voltage section of control box. Connect line power

leads to Terminals 1 and 2 on Terminal Board 1.

See label diagram and Fig. 7. Aluminum field

wiring may be used when splice connected to

copper pigtails from unit with approved copper to

aluminum splice connectors.

Accessory Electric Fleater(s) — Connect line power

leads from fused disconnect(s) to Terminal Board 2

as shown in Fig. 7. Extend power leads (supplied

with electric heater) from heater thru fan section

and thru hole provided into high voltage section of

control box. Connect leads to Terminal Board 2

(Fig. 6 and 7).

THERMOSTAT’

TERMINAL

BOARD 3

TO

HEATER

FD

TO (-

HEATER <

FD 1-

RED

BLK

—

”0—[

a

F

YEL

—

-0—0-

BLU

)

(2

TO

10 Kw

HEATER

1

TO

> 5KW

1 HEATER

FD — Fused Disconnect

______Field Wiring

______Factory-Supplied Wire (Field Connected)

Fig. 7 — Line Power Connections Evaporator Fan Motor is factory wired for high THERMOSTAT LEADS (24 v) are brought thru hole provided (Eig. 1) into low voltage section of control box. Connect leads to Terminal Board 3 as Accessory Electric Heaters — Extend control leads &- № &- -a -Q 0------------------------------------ a Connect Terminal G to Terminal 2 for operation with electric _____ Field Wiring *HH01 YA092 thermostat with HH93YZ096 subbase Fig. 8 — Thermostat Connections c — Contactor TC — Thermostat, Cooling Comp — Compressor TDR — Time-Delay Relay FC — Fan Capacitor (1FM) TH — Thermostat, Heating FR — Fan Relay Tran — Transformer IFM — Indoor Fan Motor LPS — Low-Press. Switch — Field Power Wiring OFM — Outdoor Fan Motor ___ . Field Control Wiring R — Relay NEC Class 2, 24 v. RC — Run Capacitor (Dual) o SC — Start Capacitor Marked Connections SFR — Safety Fan Relay O Unmarked Connections SR — Start Relay TB — Terminal Board □ Terminal Board Connections NOTES 1. To be wired in accordance with NEC and local codes 2 Low-pressure cutout setting 27 0 ± 4 psig. 3. Terminations in junction box suitable for NEC Class 2 control circuit, at 24 volts 4 Motor provided with inherent thermal protector, 5. Terminal G connects to terminal no 2 for operation with electric heater.Terminal G connects to terminal no. 3 for operation with out electric heater Fig. 9 — Typical System Wiring Diagram

speed operation as shown in Fig. 9. If medium or

low speed operation is desired, remove black motor

lead from Contactor Terminal 23 and replace with

blue motor lead for medium speed or red motor

lead for low speed. Tape unused leads separately.

shown in Eig. 8 and 9.

with plug (supplied with heater) thru fan section

and insert plug into receptacle located on side

panel of control box. See Fig. 6 and 9.

heater or Terminal 3 for operation without electric heater