Carrier 39E User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

1. Loosen adjusting screw locknut.

2. Turn adjustable bolt so that runout switch opens

when runout arm comes within 3/8-in. of core.

3. Tighten adjusting screw locknut. Recheck

setting.

Pressure Switch

(Fig. 2) — As filter media be

comes dirty, high-pressure drop thru media reduces

airflow. Pressure switch is factory set at 0.55 in. wg.

Field adjustment should not be necessary. When

pressure sensed by high-pressure fitting on control

panel face reaches this setting, pressure switch shuts

off amber operating light and energizes pulse gener

ator sequence relay and motor. As clean media ad

vances across airway, pressure drop across media

decreases and switch returns to illuminate amber

operating light. To check and/or adjust pressure

switch setting:

1. Shut off system air fan. Open take-up side

access door. Shut off power at fused disconnect.

Set power switch at OFF.

2. Disconnect yellow or gray motor lead at ter

minal board no. 1 (TBl-3 or 4) to prevent motor

operation. Tape off lead.

3. Set power switch at ON. Turn on power at

fused disconnect.

4. Remove red plastic cap from pressure switch to

expose adjusting screw. Do not loosen 1-in. hex

locknut. Nut is locked to provide mechanical

stop for minimum differential pressure setting.

5. Connect a draft gage to high-pressure port on

control panel.

6. Apply controlled pressure gradually to high-

pressure port until amber operating light goes

out. Note draft gage reading. This is switch set

point (factory setting 0.55 in. wg).

7. Turn adjusting screw counterclockwise to de

crease static pressure setting or clockwise to

increase static pressure setting as required. A

1/2 turn changes setting approximately 0.13

in. wg.

8. Remove draft gage. Replace red plastic cap on

adjusting screw.

9. Shut off power at fused disconnect. Set power

switch at OFF. Reconnect motor lead. Turn on

power at fused disconnect. Set power switch

at ON.

10. Perform any other operational checks as re

quired. Close and secure access door. Restore

air system operation.

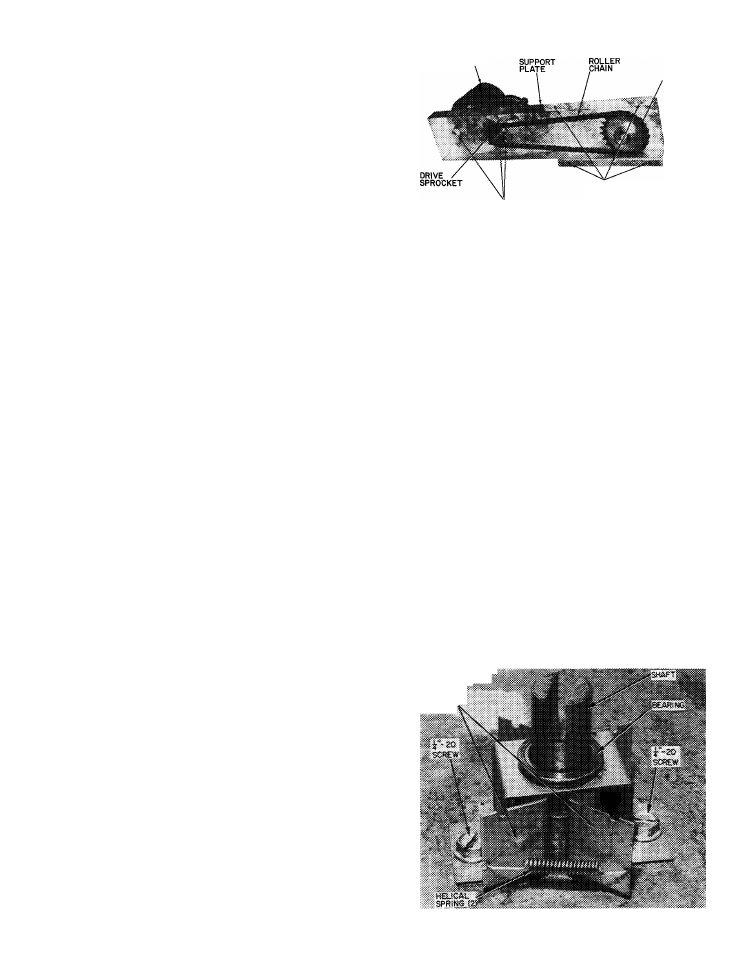

Motor Gear-Drive Assembly

(Fig. 2 and 10) —

Assembly advances clean media across filter section

airway. It consists of a motor and drive sprocket,

a roller chain and a take-up spool sprocket on a

support plate. Chain tension is factory set so that

deflection of chain at midpoint is 1/4-inch. To ad

just chain tension, loosen motor mounting bolts (3),

reposition motor on slotted mounting holes in

support plate until correct tension is achieved.

Tighten motor hold-down bolts.

MOTOR

TAKE-UP

SPOOL

SPROCKET

SUPPORT PLATE

MOUNTING HOLES (4)

MOTOR MOUNTING

BOLTS. LOOSEN FOR

TENSION ADJUSTMENT

Fig. 10 — Motor Gear-Drive Details

Lubricate chain with a light graphite oil once each

year.

Media Tension Brake

(Fig. 11) — Brake is

mounted on bottom panel of supply spool side to

provide tension on supply spool at bottom end of

spool shaft. Two brake shoes held in place by 2

helical springs cause friction (drag) required for

proper media tension. Brake assembly includes

supply spool bearing surface and slotted axis shaft.

Except for making sure that helical springs and shoes

are in tension, no other maintenance is required.

Shear Pin

— Take-up spool shaft is fastened to

keeper on take-up spool disk at base of spool by a

bolt and locknut. This bolt acts as a shear pin to pre

vent damage to motor gear-drive. In the event of

mechanical failure which could cause excessive

tension on motor gear-drive, bolt will shear allowing

motor to operate freely and continuously. Eventu

ally, amber operating light will go out (as described

elsewhere) and stay out as indication of malfunction.

Cleaning and Lubrication

— The only cleaning

necessary in addition to general housekeeping is

removal of loose fibers around shaft bearings. Shaft

bearings and gear motor require no routine main

tenance. Refer to specific component description for

additional information as required.

BRAKE

SKIES:

Fig. 11 — Media Tension Brake

11