Service – Carrier 39E User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE

Replacing Dirty Filter Media

— Rethreading

clean media roll is not necessary. When clean media

is to be installed, simply attach leader of clean media

roll to trailer of depleted (dirty) media roll as

follows;

1. Shut off system air fan. Open both side access

doors (Fig. 2). Automatic units — set manual

override switch at MANUAL.

2. Check that supply media roll has been depleted.

Swing media runout arm away from supply

spool and set media switch at ON so that motor

will advance remaining media. When paper

trailer is exposed, release runout arm (stopping

motor). Then set media switch at OFF.

NOTE: If a complete increment of clean media

can be exposed to airway before paper trailer on

supply spool is exposed, adjust media runout

switch as described later so that clean media will

not be wasted.

3. Disengage paper trailer from supply core (card

board tube). Do not operate motor at this time.

4. Lift supply spool upper shaft retainer, swing

out upper end of shaft. Remove the now empty

core from supply spool. Do not damage or dis

card core.

5. Unpack replacement supply media roll, install

it on supply spool. Replace upper end of spool

in retainer. Note correct position of roll so that

as media unrolls fluff side of media will be facing

into airstream (Fig. 2).

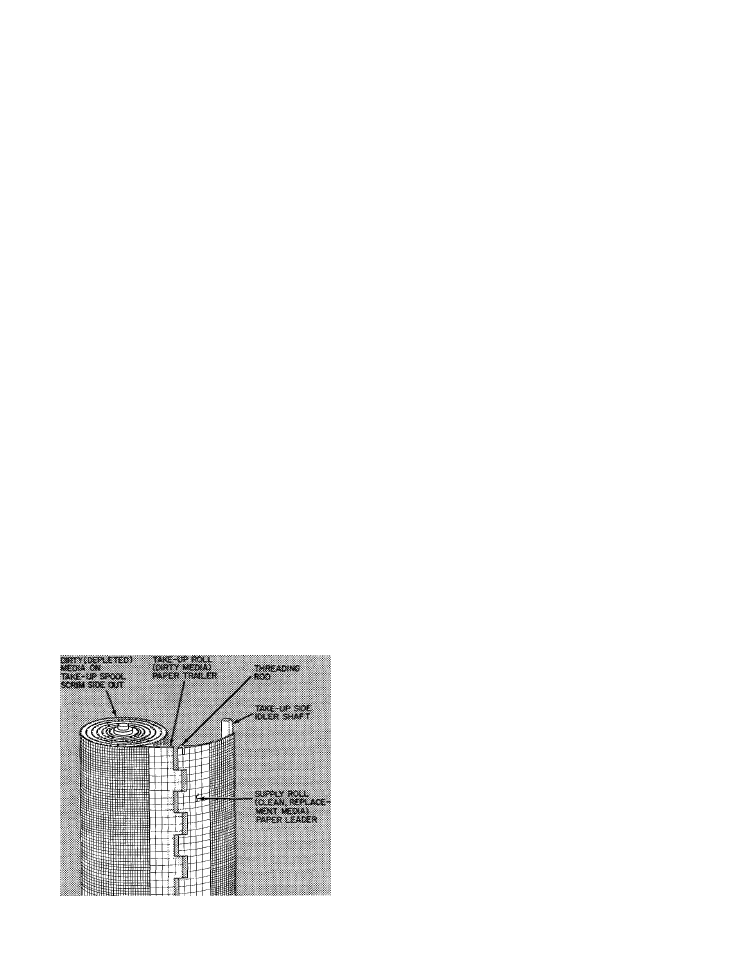

6. Connect paper leader of replacement media roll

to paper trailer of depleted media roll by using

threading rod (Fig. 9).

7. Dual-roll sections only — Jog media switch to

expose paper trailer of upper (slave) media roll.

As this is done, be sure that threading rod in

Fig. 9 — Replacement Media Roll Spliced

to Depleted Media Roll

splice in lower media rolls passes smoothly

around supply-side idler shaft and then thru

supply-side seals without snagging or wrinkling.

Repeat steps 2 thru 6 to replace upper media

roll.

8. Set media switch at ON to draw splice(s) across

airway opening. Check that threading rod(s),

splice(s) and media travel smoothly. When

(lower) threading rod and splice reach take-up

side set media switch at OFF.

9. Remove threading rod to disconnect paper

trailer of depleted roll from paper leader of

replacement roll. Replace threading rod on its

storage clips in supply side.

10. Lift take-up spool shaft retainer; swing out

upper end of take-up spool. Remove depleted

media roll from take-up spool. Pack dirty media

roll in now-empty replacement roll carton. Dis

pose of dirty media roll as suitable.

11. Install empty core (cardboard tube removed in

step 4) on take-up spool. Replace upper end of

take-up spool shaft in shaft retainer.

12. Insert leader behind strap on take-up core

(Fig. 8). Fold leader over itself. Note rotation

of take-up spool (Fig. 2).

13. Set power switch at OFF.

14. Set media switch at ON.

15. Jog power switch so that about 2 turns of clean

media roll winds up on take-up spool to secure

paper leader end of roll on to core. On dual-roll

sections this will also advance upper media roll

so that splice will pass thru upper take-up-side

seals, pass around take-up idler shaft and reach

upper take-up spool.

16. Dual roll sections — Disconnect splice in upper

depleted and replacement rolls; connect upper

replacement media roll to upper take-up spool

(i.e. repeat steps 9 thru 15). Be sure that media

travels smoothly and that paper leader is evenly

secured. Replace threading rod in its storage

clips on supply side.

17. Manual Units — Leave media switch at ON. Set

power switch at OFF.

Automatic Units — Set manual override switch

at AUTO. Set media switch at ON, then set

power switch at ON.

18. To check that all is in order, perform Opera

tional Checks as required. Close and secure

access doors before leaving job site.

Media Runout Switch

(Fig. 2) — Switch is factory

set to prevent media advancement when supply

spool media is depleted. Incorrect setting may

cause excessive media to remain on supply spool

or cause media to be pulled off supply spool core

before shutting off advance cycle.

Runout switch is activated by adjustable bolt on

runout arm when arm is 3/8-in. away from spool

core. To adjust cutout setting:

r

10