38af air-cooled condensing units, Table 3 — liquid line data, Fig. 2 — line power connections – Carrier 38AF User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

38AF

Air-Cooled Condensing Units

Table 3 — Liquid Line Data

UNIT 38AF

MAX

ALLOWABLE

LIQUID

LIFT (it)

LIQUID LINE

Max Allowable

Pressure Drop

(psi)

Max Allowable

Temp Loss

(F)

007

70

7

2

008

70

7

2

NOTE: Values shown are for units operating at 45 F saturated suction

and 95 F entering air

3-PHASE

CONN TO

DISCONNECT

PER N E C

___________________________

. SPLICE CONNECTIONS

FIELD WIRING

FACTORY WIRING

YEL-

BLK-

-BLU -

-GROUND LEAD------ GROUNDING LUG

3-PHASE COND UNIT

NOTE: Pigtail connections can use copper or aluminum wire Factory-

supplied connectors must be used when aluminum wire is used

Fig. 2 — Line Power Connections

JUMPER

TERMINAL

BLOCK

UNIT

CONTROL

BOX

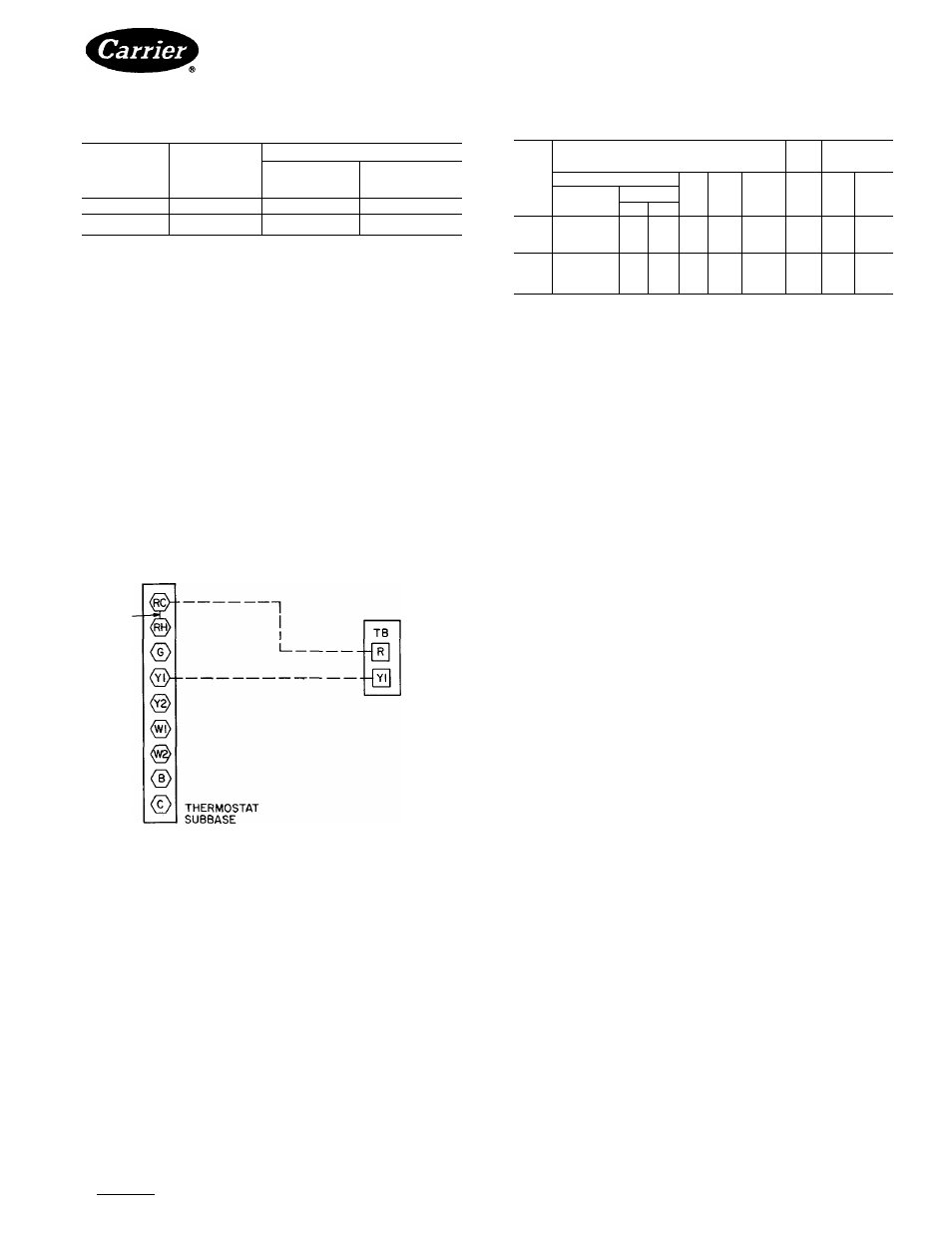

Fig. 3 — Remote Thermostat Wiring

START-UP

Preliminary Checks

1. Check that all internal wiring connections are tight

and that all barriers, covers and panels are in place.

2. Field electrical power source must agree with unit

nameplate rating.

3. All service valves must be open.

4. Crankcase heaters must be firmly seated into com

pressor crankcase.

Leak Test entire refrigerant system by pressure method

described in Carrier Standard Service Techniques

Manual, Chapter 1, Section 1-6. Use R-22 at approxi

mately 25 psig backed up with an inert gas to a total

pressure not to exceed 245 psig.

Table 4 — Electrical Data (3-Ph/60-Hz)

38AF

UNIT

FAN

COM

PRESSOR

Volts

ICF

MCA

MOCP

(Fuse)

FLAT

RLA

LRA

Nameplate

Supplied*

Min

Max

208-230

187

253

140

36 3

60

29

26 7

137

007

460

414

528

71

166

25

1 5

12 1

69

575

518

666

58

14.9

20

2.9t

9.6

55

208-230

187

253

186

44 4

60

29

32 5

183

008

460

414

528

93

20 9

25

1 5

152

91

575

518

666

76

188

25

2 9Í

124

73

FLA

— Full Load Amps

ICF

— Maximum Instantaneous

Current Flow

LRA

— Locked Rotor Amps

MCA

— Minimum Circuit Amps per NEC Section 430-24

MOCP

— Maximum Overcurrent Protection

RLA

— Rated Load Amps (compressor)

•Units are suitable for use on electrical systems where voltage supplied

to the unit terminals is not below or above the listed limits

tFan motor is single phase

j230 volts

Before starting unit, crankcase heaters must be on for '

24 hours to be sure all refrigerant is out of the oil. To

energize crankcase heaters, proceed as follows; set space

thermostat above ambient so there will be no demand for

cooling. Close field disconnect. The crankcase heaters '

are now energized.

Evacuate and Dehydrate entire refrigerant system

by either of the methods described in Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-7.

Charge System — Refer to Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-8.

Using liquid charging method and charging by weight

procedure, charge to a clear sight glass. After proper

charge has been determined, indicate this amount on

unit’s aluminum informative plate section entitled

“Refrig./System R-22.”

To Start Unit — Assuring that crankcase heater has

been on for 24 hours and field disconnect is closed, set

room thermostat below ambient. Unit compressor will

start after a 15-second delay.

SERVICE

Crankcase Heater prevents refrigerant migration and

compressor oil dilution during shutdown when com

pressor is not operating. If crankcase heater is da-

energized for more than 6 hours, both compressor service

valves must be closed.

Condenser Fan is supported by a reinforced wire

guard to which the fan motor is bolted.

Figure 4 shows proper mounted fan position.

Lubrication

FAN MOTORS have permanently sealed, lubricated

bearings. Do not oil.

COMPRESSOR also has its own oil supply.

CONDENSER FAN ADJUSTMENT (Fig. 4) — Shut

off unit main power supply. Remove condenser fan

assembly (grille, motor, motor cover and fan) and loosen

fan hub setscrews. Adjust fan height as shown in Fig. 4.

Tighten setscrews and replace fan assembly.

Cleaning Coils ^ Coils can be cleaned with a vacuum

cleaner, washed out with water, blown out with com

pressed air, or brushed (do not use wire brush). Fan

motors are drip proof but not waterproof.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 11 14

PC111

Catalog No 563-852

PrintedinUSA

Form38AF-1SI

Pg3

4-85

Replaces: New

For replacement items use Carrier Specified Parts.

Tab I3al2a