38af air-cooled condensing units – Carrier 38AF User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING & COOLING

38AF

Air-Cooled Condensing Units

Step 3 — Complete Refrigerant Piping

Connections

SIZE REFRIGERANT LINES — Consider length of

piping required between condensing unit and evaporator,

amount of liquid lift, and compressor oil return. See

Table 3 and also refer to Part 3 of Carrier System Design

Manual for design details and line sizing. Refer to evap

orator installation instructions for additional information.

USE FILTER DRIER AND MOISTURE INDICATOR

— The filter drier is factory supplied. Moisture indicator

(sight glass) is a field-installed option and should be

installed just after liquid line shutoff valve. Do not use a

receiver; there is none provided with unit and one should

not be used.

MAKE PIPING CONNECTIONS — Remove block-off

in corner post and unsweat caps from liquid and suction

lines.

NOTE: Unit is shipped with R-22 holding charge. System

pre.ssure must be relieved before unsweating caps.

Pass nitrogen or other inert gas through piping while

brazing to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve(s)

to evaporator section. If 2 thermostatic expansion valves

are installed for 2-step cooling, install field-supplied

liquid line solenoid valve ahead of the second expansion

valve.

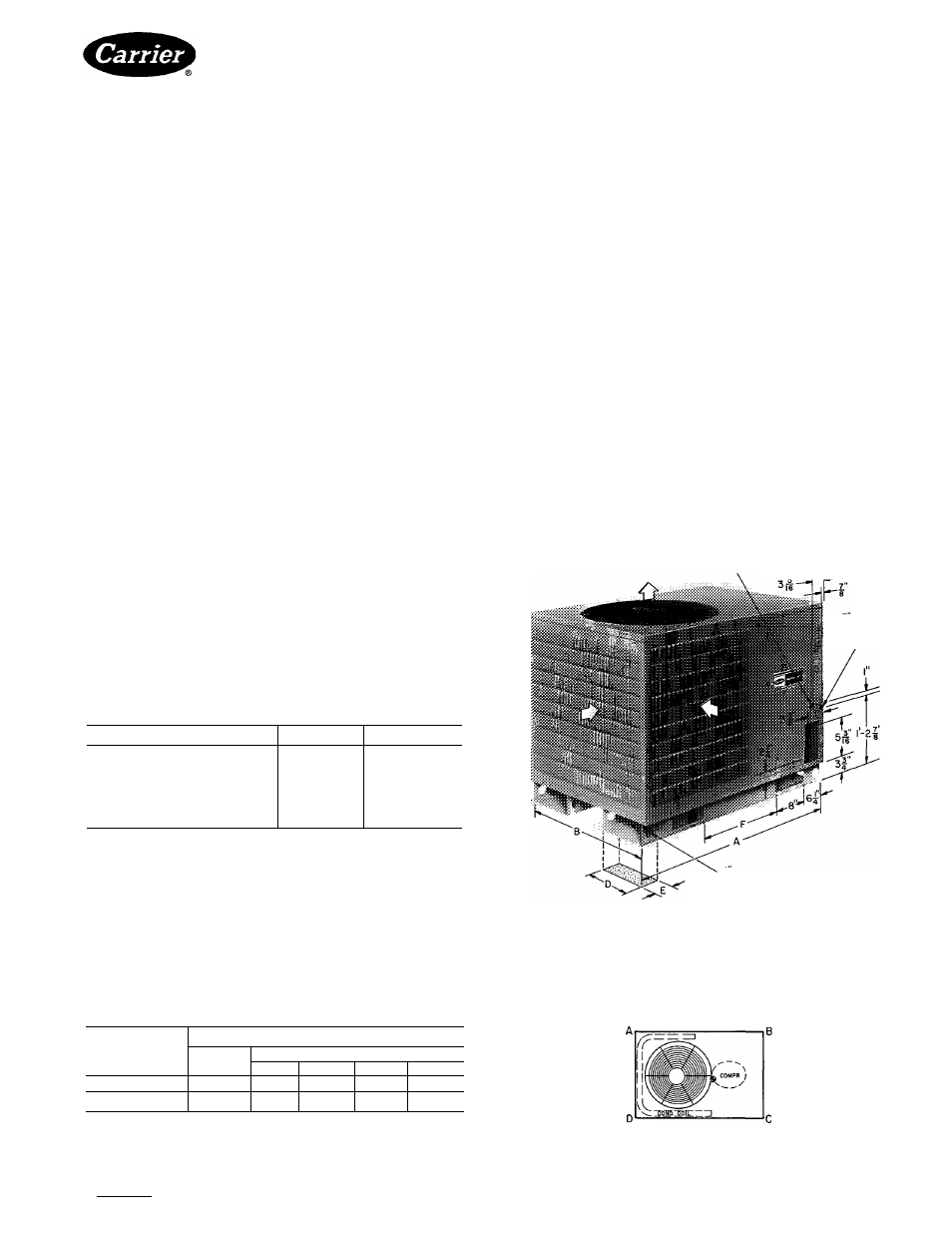

DIMENSIONS (ft-in.)

UNIT 38AF

007

008

Length

A

2-9

4- 0%

Width

B

2-9

2- 8Va

Height

c

2-8

2-11

'/s

Base Rail Width

D

0-10'/2

O-IO'/j

Minimum Support

E

0-4

0- 4

Lift opening

separation

F

1- 0’/4

1-10

NOTE Units may be installed with any one side, except compressor access

side, within one ft of wall or other airflow obstruction as long as remaining

sides have at least 3 ft clearance Compressor side access is always 3 feet

Units may be located side by side with a minimum of 3ft between units

Allow at least a 5-ft clearance above the unit

PROVIDE SAFETY RELIEF —A fusible plug is located

in unit liquid line. Do not cap this plug. If local code;

requires additional safety devices, install as directed.

Step 4 — Complete Electrical Connections

POWER WIRING — Unit is factory wired for voltage

shown on nameplate. Provide adequate fused disconnect

switch within sight of unit, readily accessible, but out of

reach of children. Provision for locking switch open (ofO

is advisable to prevent power from being turned on while

unit is being serviced. Disconnect switch, fuses, and field

wiring must comply with National Electrical Code and

local code requirements.

Route power wires through opening in unit side panel

and connect in unit control box as shown on unit label

diagram and Fig. 2. Unit must be grounded.

Affix crankcase heater warning sticker to unit dis

connect switch.

CONTROL CIRCUIT WIRING — Control voltage is

24 volts. See Fig. 3 and unit label diagram for field-

supplied wiring details. Route control wires through

opening in unit side panel to connection in unit con

trol box.

if" HOLE FIELD POWER SUPPLY

i HOLE

CONTROL

POWER

l-b

rigging

HOLE (8)

Fig. 1 — Dimensions (ft-in.)

Table 2 — Weight Distribution

WEIGHT (lb)

UNIT 38AF

Oper

Support Point

Wt

A

B

C

D

007

300

54

78

100

68

008

410

75

116

133

86

REAR

LEFT

RIGHT

FRONT

TOP VIEW

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 11 14

PC111

Catalog No 563-852

PrintedInUSA

Form38AF-1SI

Pg2

4-85

Replaces: New

For replacement items use Carrier Specified Parts

Tab |3al2a