Carrier 38AF User Manual

Installation, start-up and service instructions, 38af air-cooled condensing units, A warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING & COOLING

38AF

Air-Cooled Condensing Units

Installation, Start-Up and Service Instructions

SAFETY CONSIDERATIONS

Installing and servicing air conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install or service air conditioning equipment.

Untrained personnel can perform basic maintenance,

such as cleaning and replacing filters. All other opera

tions should be performed by trained service personnel.

When working on air conditioning equipment, observe

precautions in literature and on tags and labels attached

to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instruc

tions thoroughly. Consult local building codes and

National Electrical Code (NEC) for special installation

requirements.

A WARNING

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Turn off accessory heater power if

applicable. Electrical shock can cause personal injury.

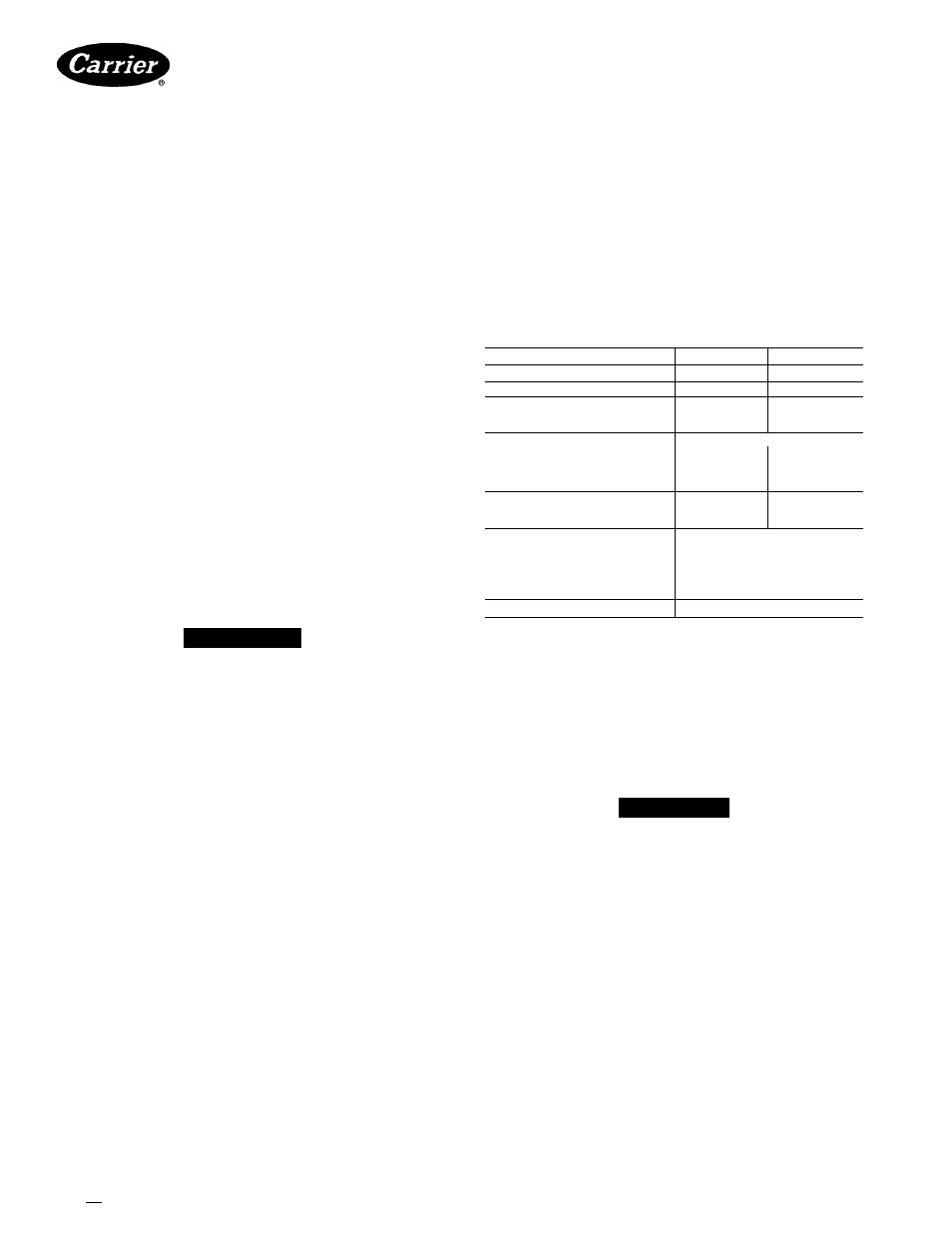

Table 1 — Physical Data

UNIT 38AF

007

008

OPER WEIGHT (lb)

300

400

REFRIGERANT*

22

22

COMPRESSOR

Oil (pts)

46

8 0

Crankcase Heater Watts

40

40

CONDENSER AIR FAN

Propeller; Direct Drive

Number...Rpm

1 1075

1 1075

Diameter (in.)

22

22

Motor Hp (NEMA)

'/2

v?

Nominal Cfm Total

3500

4300

CONDENSER COIL

Face Area (sq tt)

108

17 7

Storage Capacity (lb)f

168

18 0

CONTROLS

Pressurestat Settings

High Cutout

426 ±

7 psig

Cut-in

320 ± 20 psig

Low Cutout

27 ±

4 psig

Cut-In

67 ±

7 psig

FUSIBLE PLUG

200 F

*Unit is factory supplied with holding charge only.

tStorage capacity of condenser coil with coil 80% full of liquid R-22

at 124 F

INSTALLATION

Step 1 — Complete Pre-Installation Checks

UNCRATE UNIT — Remove unit packaging except for

the top skid assembly and wood bumpers, which should

be left in place until after unit is rigged into place.

INSPECT SHIPMENT — File claim with shipping com

pany if shipment is damaged or incomplete.

CONSIDER SYSTEM REQUIREMENTS

• Consult local building codes and National Electrical

Code (NEC) for special installation requirements.

• Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit. See Fig. 1.

• Locate unit so that condenser airflow is unrestricted

on all sides and above. Refer to Fig. 1.

• Unit may be mounted on a level pad directly on base

channels or mounted on raised pads at support points.

See Table 2 for weight distribution based on recom

mended support points.

NOTE: If vibration isolators are required for a parti

cular installation, use data in Table 2 to make proper

selection.

Step 2 — Rig and Mount the Unit

A CAUTION

Be sure unit panels are securely in place prior to

rigging.

RIGGING — These units are designed for overhead

rigging only. Traverse base channels are provided with

1 -1 / 2 in. rigging holes that are located 1 -3/ 4 in. from each

end. Rig with top skid packaging assembly and wood

bumper strips in place to prevent unit damage by rigging

cable. As further protection for coil faces, plywood sheets

may be placed against sides of unit, behind cables. Run

cables to a central suspension point so that angle from the

horizontal is not less than 45 degrees. Raise and set unit

down carefully.

If it is necessary to roll unit into position, mount unit

on longitudinal rails, using a minimum of 3 rollers. Apply

force to rails, not unit. If unit is to be skidded into posi

tion, place it on a large pad and drag it by the pad. Do not

apply any force to unit.

Raise from above to lift unit from rails or pad when

unit is in final position.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without Incurring obligations.

BookM |4

PC111

Catalog No 563-852

PrintedinUSA

Form38AF-1SI

Pg 1

4-85

Replaces: New

For replacement items use Carrier Specified Parts

Tab I3al2a