Important- read before installing, Installation step 1—rig and place unit, A caution – Carrier 48KHA User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 1—Performance Data

MODEL 48-

COOLING

CAPACITY

(Btuh)*

RATED

HEATING

INPUT

(Btuh)

OUTPUT

CAPACITY

(Btuh)

ARI*

SOUND

RATING

(Bels)

KLA118310BE

17,800

40,000

32,000

7.8

KLA124310BE

23,800

40,000

32,000

7.8

KHA024310BF

24,000

75,000

58,000

8.0

KLA130310BE

29,600

40,000

32,000

7.8

KHA030310BF

29,600

75,000

58,000

7.8

KLA136310BE

36,000

60,000

47,000

8.0

KLA136510CE

36,000

60,000

45,000

8.0

KLA136610CE

36,000

60,000

45,000

8.0

KHA136310BE

36,000

100,000

79,000

8.0

KHA136S10CE

36,000

100,000

75,000

8.0

KHA036310BF

36,000

125,000

97,000

8.0

KHA036510CF

36,000

125,000

93,750

8.0

KLA142310BE

42,000

60,000

47,000

78

KLA142510CE

42,000

60,000

45,000

7.8

KHA042310BF

42,000

125,000

97,000

7.8

KHA042510CF

42,000

125,000

93,750

7.8

KLA148310BE

49,000

80,000

63,000

8.4*

KLA148510CE

49,000

80,000

60,000

8.4*

KLA148610CE

49,000

80,000

60,000

8.4*

KHA048310BE

49,000

125,000

97,000

8.4*

KHA048510CF

49,000

125,000

93,750

8.4*

KLA160310BE

60,000

100,000*

79,000*

8.4*

KHA060310BF

60,000

150,000*

116,000*

8.4*

♦Rated in accordance with U S. Government D.O.E. test procedures and/

or ARI Standard 210-81.

tSound rating per ARi 270-84.

tThe capacity ratings of singie-phase units are in accordance with U.S.

Government D.O.E. test procedures and/or AGA certification require

ments. For 3-phase units, the efficiency rating is a product thermai effi

ciency rating determined under continuous operating conditions, inde

pendent of any installed system.

All units can be connected into existing duct systems that

are properly sized and designed to handle an airflow of 350

to 450 cfm per each 12,000 Btuh of rated cooling capacity.

See Table 8 for cooling euid heating airflow requirements.

NOTE:

When insteJling any accessory item, see Installation

Instructions packaged with accessory.

IMPORTANT-

READ BEFORE INSTALLING

1. This instEdlation must conform with all applicable

local and nationed codes.

2. Power supply (volts, hertz and phase) must corre

spond to that specified on unit rating plate.

3. Electrical supply provided by utility must be suffi

cient to handle load imposed by unit.

4. Refer to Fig. 4 for locations of gas inlet, electrical

inlets, condensate drain, duct connections, and

required clearances before setting unit in place.

5. Locate unit where vent cap will be a minimum of 4 ft

from openable windows or doors.

6. Installation must conform with local building codes

and with National Fuel Gas Code, NFPA 54-1984/

ANSI Z223.1-1984.

IMPORTANT: On some models, the high-voltage igni

tion cable is not connected to the spark generator termi

nal on the control head/gas valve assembly when shipped

from the factory. The cable is fastened to the manifold on

these models. Push the boot toward center of the cable to

expose the connector on the end of the cable. Attach the

connector securely to the terminal on the end of the con

trol head/gas vedve assembly. Push the boot over connec

tor to insulate the high-voltage connection.

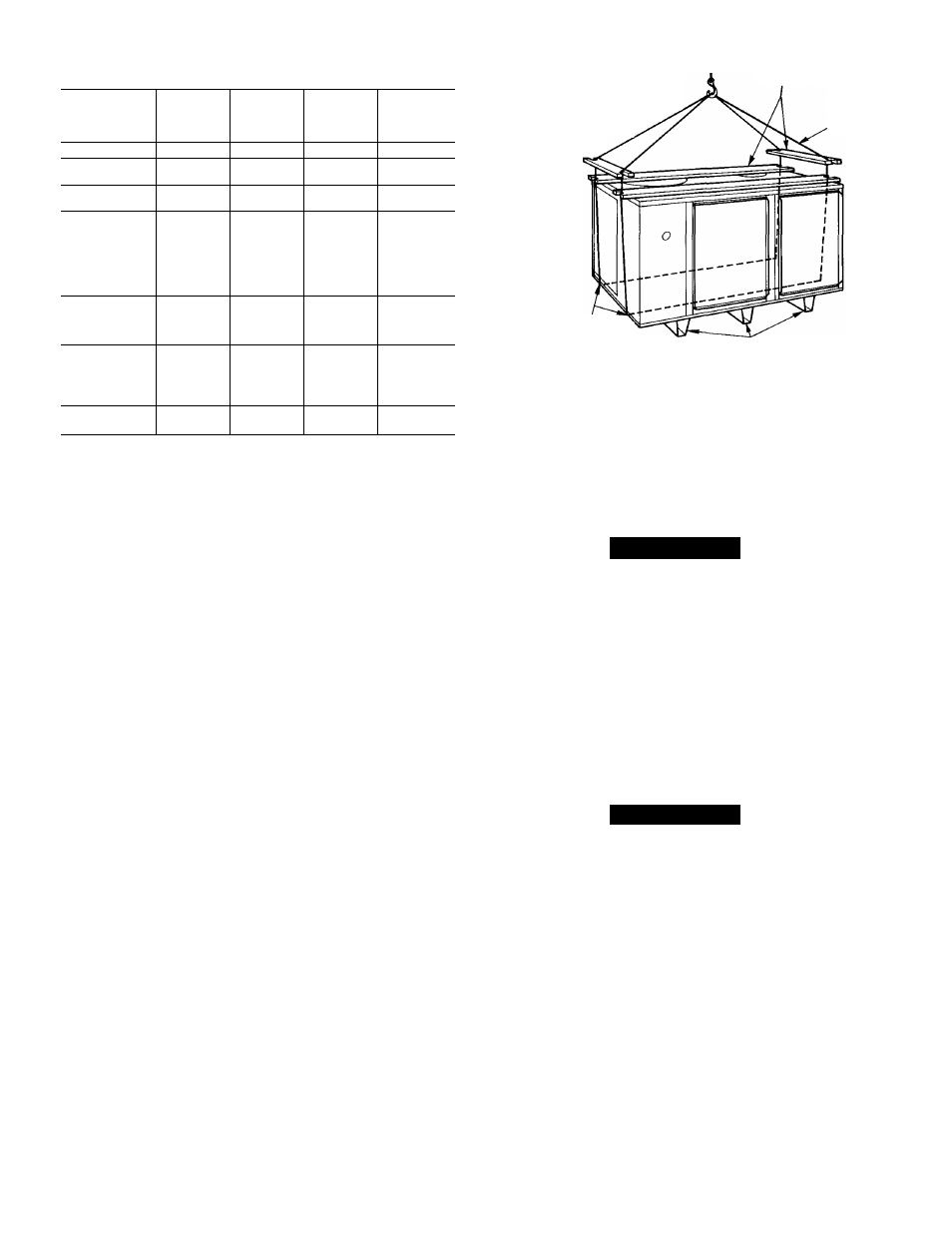

SPREADER OARS'

^

(2)2x4xUNIT LENGTH PLUS 10"WITH

11 DEEP 90° NOTCHES EACH END

(2) 2x4xUNIT WIDTH WITH l^

DEEP 90° NOTCHES

EACH END

SPREADER BARS

LOCATE CHAINS THROUGH

HOLES IN BASE

CHANNELS

CHAIN

TWO OR THREE BASE

CHANNELS ATTACHED TO

BOTTOM OF UNIT

Fig. 2—48KHA,KLA Suggested Rigging

INSTALLATiON

Step 1—Rig and Place Unit

A CAUTION

When rigging unit to be hfted, use spreader bars to pro

tect top and sides. Rig unit as shown in Fig. 2. Use

extreme caution to prevent damage when moving unit.

Unit must remain in upright position during all rigging

and moving operations. Unit must be level for proper

condensate drainage; therefore, the ground-level pad or

accessory roof-mounting curb must be level before set

ting unit in place. When a field-fabricated support is

used, ensure that support is level and properly supports

unit and plenum.

ROOFTOP INSTALLATION

A CAUTION

When installing a unit on a rooftop, be sure roof will

support the additioneil weight. Refer to Fig. 4 to obtain

total weight and corner weight information.

When installing a Model 48KHA,KLA end discharge unit

with a field-supplied downflow plenum, a field-supplied roof

mounting curb must be installed on emd flashed into roof

before

unit

installation.

When

installing

a

Model

48KHA,KLA end discharge unit without a downflow ple

num, place unit on a level base that provides proper sup

port. On flat roofs be sure unit is located at least 4 in. above

highest expected water level on roof to prevent flooding.

Consult local codes for additional installation requirements.

GROUND LEVEL INSTALLATION-Place unit on a

solid, level concrete pad that is a minimum of 4 in. thick and

that extends approximately 2 in. beyond casing on all sides

of unit. Do not secure unit to pad except when required by

local codes.

CLEARANCES—Required minimum operating and service

clearances are shown in Fig. 4 for providing adequate com

bustion, ventilation emd condenser edr.