A caution, Service – Carrier 48KHA User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

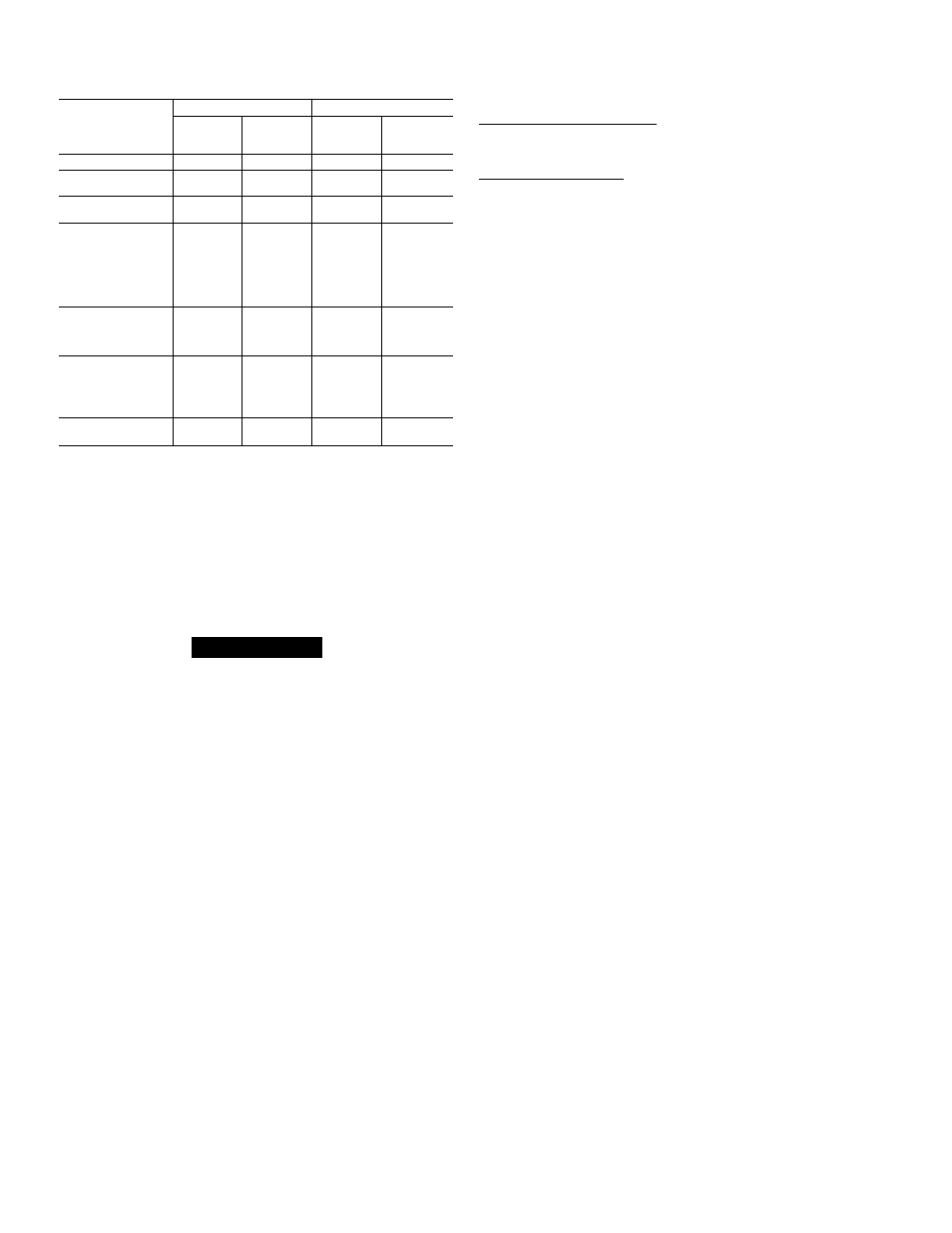

Table 8—Rated Cooling and Heating Airfiows

MODEL 48-

COOLING

HEATING

Rated

Airflow

(dm)*

ESP

(in. wg)

Rated

Airflow

(cfm)*

Maximum

ESP

(in. wg)*

KLA118310BE

630

0.10

505

0.30

KLA12431 QBE

800

0.10

505

0.30

KHA024310BF

800

0.10

947

0.30

KLA13031 QBE

1000

015

462

0.30

KHA030310BF

1000

0.15

947

0.30

KLA136310BE

1200

0.15

758

0.30

KLA136510CE

1200

0.15

758

0.65

KLA136610CE

1200

0.15

758

0.65

KHA136310BE

1200

0.15

1155

0.30

KHA136510CE

1200

015

1155

0.65

KHA036310BF

1200

0.15

1445

0.30

KHA036510CF

1200

0.15

1445

0.65

KLA142310BE

1400

015

695

0.30

KLA142510CE

1400

0.15

695

0.65

KHA042310BF

1400

0.15

1445

0.30

KHA042510CF

1400

0.15

1445

0.65

KLA148310BE

1600

0 20

925

0.30

KLA148510CE

1600

0.20

925

0.65

KLA148610CE

1600

0.20

925

0.65

KHA048310BF

1600

0.20

1445

0 30

KHA048510CF

1600

0.20

1445

0.65

KLA160310BE

2000

0.20

1155

0.30

KHA060310BF

2000

0.20

1735

0.30

ESP

—External Static Pressure

♦Rated in accordance with U.S Government D.O.E. test procedures and/

or ARI Standard 210-81

NOTE:

When operating the 208/230-volt, 3-phase versions

of Model 48KHA048 at 208 volts, lead connections of

blower motor must be changed as indicated on unit wiring

label to ensure proper airflow.

A CAUTION

Do not change blower-motor lead connections on 460-v

units from factory setting.

Heating and/or cooling airflow of 208/230-v direct-drive

blower motors can be changed by changing the lead con

nections of blower motor. Motor leads are color-coded as

follows:

black—high, speed

blue —medium speed

red —low speed

NOTE:

Some direct-drive blower motors do not bave lead

for medium speed. Factory connections and available

optional connections are shown in Table 6.

For all units, motor lead connected to heat relay determines

heating speed and resulting airflow; and motor lead con

nected to cooling relay determines the cooling speed and

resulting airflow. See unit wiring label.

To change heating and/or cooling speed, connect appropri

ate color-coded lead to appropriate relay. Be sure to prop

erly insulate any unused motor lead. See Make Wiring

Connections, Special Procedures for 208-v Operation section

for proper procedures to insulate an unused electrical lead.

When installing a 208- or 230-v direct-drive unit that is

factory-connected for heating and cooling speeds that are

not the same, and seune speed for both heating and cooling

is required for a particular application, connect appropriate

color-coded lead to terminal 2 of cooling relay and connect a

field-supplied jumper between heat relay and terminal 2 of

cooling relay. Be sure to properly insulate unused motor

lead(s).

CONTROLS—All compressors have the following interned-

protection controls:

High-Pressure Relief Valve—This vedve opens when pres

sure differential between low and high side becomes

excessive.

Compressor Overload—This overload interrupts power to

compressor when either current or internal temperature

becomes excessive, and automaticedly resets when internal

temperature drops to a safe level. This overload may require

up to 60 minutes (or longer) to reset; therefore, if internal

overload is suspected of being open, disconnect electrical

power to unit and check circuit through overload with an

ohmmeter or continuity tester.

COOLING SEQUENCE OF OPERATION-The following

sequence of operation pertains to all 208/230-volt, 3-phase

units; however, sequence of operation of single-phase and

460-volt units is very similar. Refer to wiring diagram in

Fig. 10.

NOTE:

Although actued unit wiring may vary slightly from

that shown in Fig. 10, sequence of operation will not be

affected.

With room thermostat selector switch in the COOL position

and fan switch in AUTO, position, cooling sequence of oper

ation is as follows:

When room temperature rises to a point slightly above cool

ing control setting of thermostat, thermostat cooling bulb

tilts and completes circuit between thermostat terminal R

to terminals Y and G. These completed circuits through the

thermostat connect contactor coil (through unit wire Y) and

relay coil (through unit wire G) across the 24-volt secondary

of transformer.

The 2 sets of normally open contacts of energized contactor

2D close and complete circuit through compressor motor 3F

and condenser fan motor 3D1. Both motors start instantly.

The set of normally open contacts of energized relay closes

and completes circuit through evaporator blower motor.

Blower motor starts instantly.

NOTE:

Three-phase units are equipped with a 2-speed con

denser fan motor and a temperature-actuated switch. Fan

motor operates at high speed when outdoor temperature

rises to 75 ±3 F and continues to operate at high speed

until outdoor temperature drops to 61 ±4 F. At 61 F or

lower, fan motor operates at low speed and permits cooling

operation down to 40 F.

Cooling cycle remains on until room temperature drops to a

point slightly below cooling control setting of room thermo

stat. At this point, thermostat cooling bulb tilts and breaks

circuit between thermostat termined R to terminals Y and

G. These open circuits de-energize contactor coil and relay

coil. Condenser, compressor and blower motors stop. Unit is

in a standby condition, waiting for next call for cooling from

room thermostat.

SERVICE

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic meiinte-

nance must be performed on this equipment. This combina

tion heating/cooling unit should be inspected at least once a

year by a qualified service person.

NOTE TO EQUIPMENT OWNER: Consult your local

deeder about the availability of a maintenance contract.

16