Standard, Fig. 9—burner flames, Standard fig. 9—burner flames – Carrier 48KHA User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

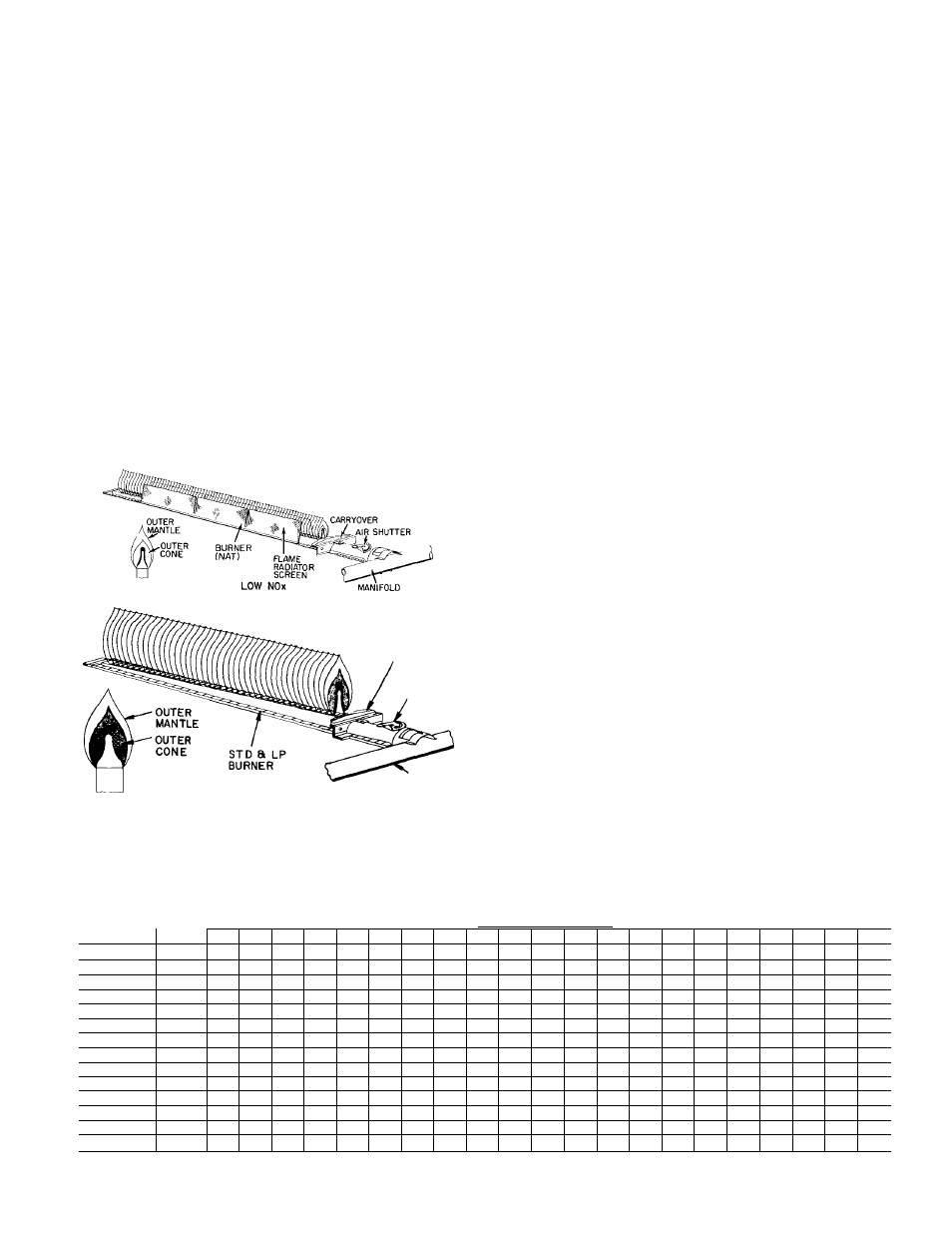

ADJUSTING BURNER AIR SHUTTERS-After burners

have operated at full input for at least 10 minutes, adjust

primary air to each burner to ensure optimum heating per

formance. Make these adjustments when unit is being

installed and during routine maintenance inspections at

beginning of each heating season. Be sure each burner is

clean and free of deposits before adjusting primary air.

Primary air to each burner is regulated by burner air shut

ter on each burner. See Fig. 9 (Burner Flames, Standard) for

location of burner air shutter. With all burners operating,

adjust primary air to each burner as follows:

1. Loosen locking screw that secures air shutter in place

on burner, then partially close air shutter until a slight

yellow tip appears on top of burner flames.

2. Open air shutter very slowly until yellow tip just disap

pears, then secure air shutter in place with locking

screw.

3. Repeat steps 1 and 2 for each burner.

After air shutter adjustments have been completed, observe

that flames on each burner are light blue and soft in appear

ance, and that flames are same height along entire length of

each burner. See Fig. 9.

CARRYOVER

AIR

SHUTTER

STANDARD

Fig. 9—Burner Flames

MANIFOLD

BLOWER HEAT-RELAY OPERATION-Heating relay

(see Fig. 6 and unit wiring diagram) is located in the control

box and adjusts to permit either longer or shorter OFF

cycles. The ON cycle automatically adjusts as OFF cycle

changes. Adjusting level on relay is factory-set at center

position to provide optimum performance for most installa

tions. On unusual installations, or where line voltage is con

siderably above or below rated voltage, an increase or

decrease may be required for length of time blower remains

on. To increase blower operation time, move adjusting lever

toward right-hand position. To decrease blower operation

time, move lever toward left-hand position.

AIRFLOW AND TEMPERATURE RISE-The heating

section of each size of unit is designed and approved for

heating operation within temperature rise range stamped on

unit rating plate.

Table 5 shows approved temperature rise range for each

unit and air delivery (cfm) at various temperature rises.

Heating operation airflow must produce a temperature rise

that falls within the approved range. Refer to Cooling Sec

tion Start-Up and Adjustments—Indoor Airflow emd Air

flow Adjustments to adjust heating airflow when required.

HEATING SEQUENCE OF OPERATION—See Fig. 10

Models 48KHA,KLA have an intermittent electric-spark

ignition system without a standing flame. When manual

shutoff is opened, gas flows to gas valve. On a call for heat

ing by the thermostat, unit terminal R makes to unit termi

nal W. Pilot veJve solenoid of gas valve and spark generator

are energized. Gas flows to pilot and the pilot is ignited

within 4 seconds. The flame sensor proves the presence of

pilot flame within 0.8 seconds after pilot ignition. The inter

nal switching of gas valve de-energizes spark generator,

energizes meun valve solenoid and energizes heating delay

relay. Gas flows to medn burners and is ignited by pilot

flame. Contacts of heating relay close between 60 and 90

seconds after burners are ignited, and blower motor starts.

Heating cycle is now in normeil operation. Unit will continue

operating in heating cycle until thermostat is satisfied.

When this occurs, the thermostat switching removes 24-volt

control circuit voltage instantly; however, contacts of de

energized heating relay remain closed and keep blower

motor running for an additional 2 to 3 minutes. Contacts of

heating relay open after 2- to 3-minute delay and blower

motor stops. Heating section is now in a standby condition

wmting for another call for heating from thermostat.

Table 5—Air Delivery (cfm) at Indicated Temperature

Rise and Rated Heating Input

MODEL 48-

HTG

INPUT

TEMPERATURE RISE(F)

(Btuh)

35

37

39

41

43

45

47

49

51

53

55

57

59

61

63

65

67

69

71

73

75

KLA118

40,000

794

751

712

678

646

617

591

567

545

524

505

487

471

455

441

427

_

—

—

—

—

KLA124

40,000

794

751

712

678

646

617

591

567

545

KHA024

75,000

—

—

—

—

1212

1158

1109

1063

1022

983

947

914

883

854

827

809

778

—

—

—

—

KLA130

40,000

794

751

712

678

646

617

591

567

545

524

505

487

471

455

KHA030

75,000

—

—

1271

1212

1158

1109

1063

1022

983

947

914

883

854

KLA136

60,000

1190

1126

1068

1016

969

926

887

850

817

786

758

731

706

683

KHA036/136

100,000

1984

1877

1781

1694

1615

1543

1478

1417

1362

1310

1263

1218

1177

1138

1102

1068

1036

1006

978

951

926

KHA036

125,000

—

—

—

2117

2019

1930

1846

1771

1701

1638

1579

1523

1472

1423

1378

1336

1296

1258

1223

1189

1158

KLA142

60,000

1190

1128

1068

1016

969

926

887

850

817

786

758

731

706

683

661

641

622

604

587

571

556

KHA042

125,000

—

—

~

—

_

1930

1846

1771

1702

1638

1579

1523

1482

1423

1378

1326

1296

1258

1223

1189

—

KLA148

80,000

1587

1502

1425

1355

1292

1235

1182

1134

1089

1048

1010

975

942

911

—

—

—

—

—

—

—

KHA048

125,000

—

—

2326

2117

2019

1930

1846

1771

1702

1638

1579

1523

1472

1423

1378

1336

1296

—

—

—

—

KLA160

100,000

1984

1877

1781

1694

1815

1543

1478

1417

1362

1310

1263

1218

1177

1138

1102

—

—

—

_

—

—

KHA060

150,000

—

-

—

—

—

2325

2226

2135

2051

1974

1902

1835

1773

1715

1660

1609

1561

1516

1493

1483

1395

NOTE: Bolder ratings

in table fall

range of the unit Dashed areas of

below the approved temperature rise

the tabie faii beyond the air delivery

capabiiity of the unit within the operating voitage range for aii voltage

options for each size unit.

11