Condenser air duct insulation – Carrier 09BB User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SWEAT CONNECTIONS

1. Cut tubing to length and remove burrs. Be care

ful not to expand tubing.

2. Clean tubing. Remove plug and nut from fitting.

3. IMPORTANT - Remove O ring from inside

fitting. Wrap entire valve with wet rag.

4. Insert tubing in fitting and solder with low-

temperature solder (450 F) such as Allstate

430.

INTERNAL DRAINAGE - The base pan has a

3/4-in. coupling for an interior drain outlet (for

rainwater). Remove the plug from the drain out

let and install a trap in the piping if this system

is used.

IMPORTANT: For vertical discharge unit,

provide a rain drain on back of unit (Fig. 5).

On ail units, before connecting drains trim

away insulation blocking the hole{s).

NOTE: Make solder connection at 50BB

unit, then connect to 09BB unit except for

soldering. Purge with 50B3 holding charge,

then solder.

Brackets

- After installing piping from 50BB to

09BB units, install the following:

HOT GAS LINE BRACKET - Install proper size

rubber-coated clamp assembly (furnished in 50BB

fastener package) to hot gas line bracket (Fig. 3).

CHANNEL AND PLATE ASSEMBLY - Figure 3

illustrates correct assembling and positioning for

this assembly.

Remote Piping

- For 09BB remote installation,

select pipe sizes according to length from the

following table.

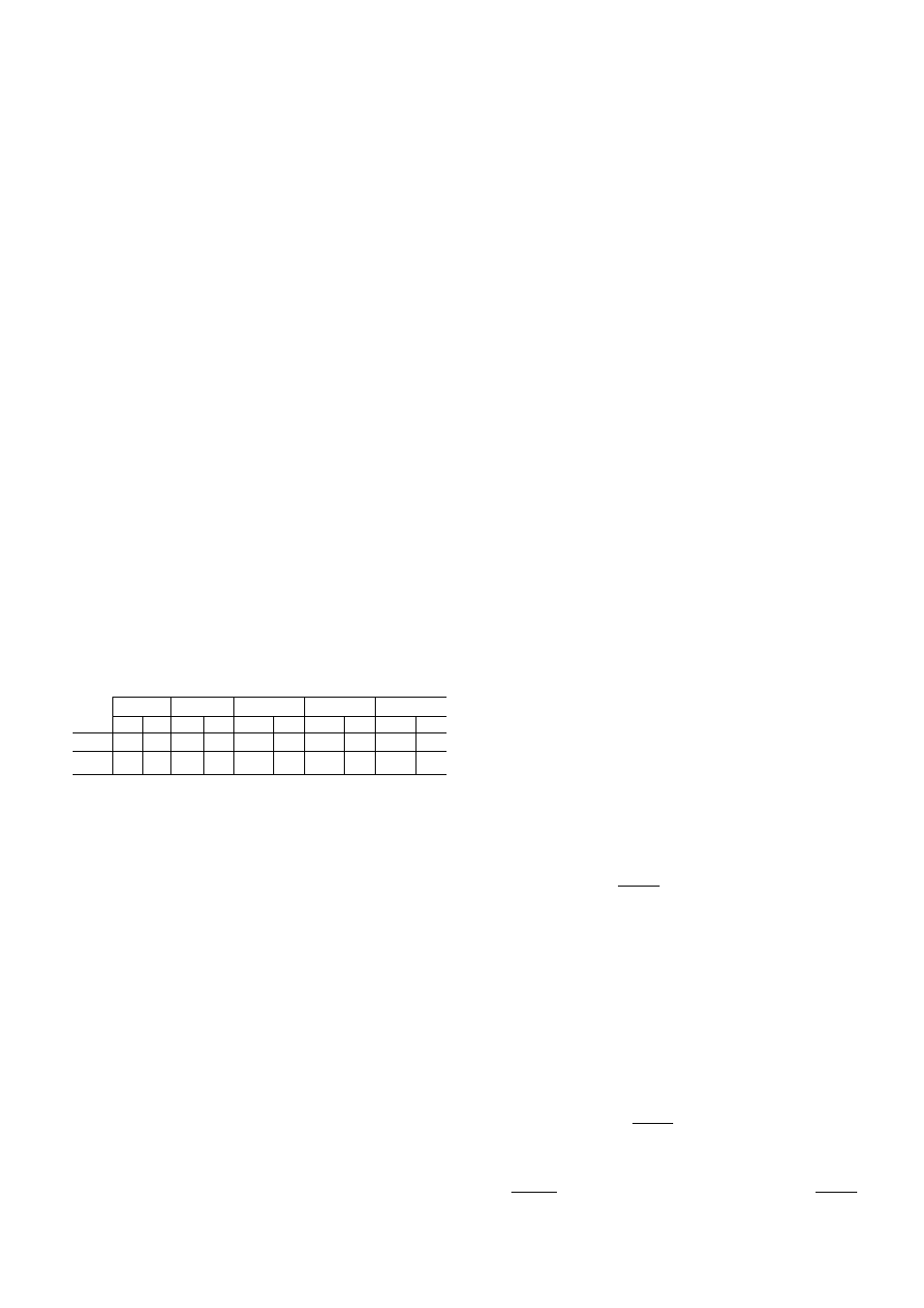

Table 2 - Remote Pipe Sizing (in.)

LENGTH OF PIPE

UINI

1

50BB

0-15 (ft)

16-25 (ft)

26-50 (ft)

51-75 (ft)

76-100 (ft)

HG

Liq

HG

Liq

HG

Liq

HG

Liq

HG

Liq

008

3/4

5/8

7/8

5/8

7/8

5/8

1

-

1/8

7/8

1

-

1/8

7/8

012

3/4

5/8

7/8

7/8

1

-

1/8

7/8

1

-

1/8

7/8

1

-

1/8

7/8

HG — Hot Gas Line

Liq — Liquid Line

NOTES;

1. Normal number of elbows and fittings have been considered in

sizing pipes.

2. Pressure loss thru recommended hot gas line check valve has

been considered for 25-100 ft lengths.

3. Use of

0

hot gas line check valve is recommended on 50BB012

units with field-supplied piping.

To connect piping, use instructions previously

given for compatible fittings. Use refrigerant

grade piping. If tubing size is other than unit con

nection sizes, use adapter fittings.

Refer to 50BB Installation Instructions to de

termine refrigerant charge adjustment for remote

piping.

Drains

- The 09BB unit provides a choice of two

drain systems for installation. The choice is gov

erned by unit location.

EXTERNAL DRAINAGE - If unit is located with

front panel outside of building, there are four

7/8-in. knockouts that can be used for external

drainage (Fig. 1).

Pitch drain pipes downward for proper drain

age. Provide tees plugged one side for cleanouts.

Leave clearance for servicing. Observe local

sanitary codes.

For other piping details refer to Carrier Sys

tem Design Manual.

Ductwork

- The 09BB unit is designed for use

without ductwork or rain louvers. If either is used,

care must be taken to eliminate air recirculation.

Recirculation can be minimized by blocking the

front discharge and discharging thru an extension

elbow. When properly designed, hinged discharge

louvers can be applied to ductwork, also to the con

denser air discharge. Fixed rain louvers over dis

charge outlets can cause excessive recirculation

and nuisance high-pressure switch cutouts. Ob

structions closer than 20 ft to the discharge air

pattern can cause significant recirculation.

If ductwork is used from standard discharge

openings and another "bird screen” is provided,

remove Carrier supplied screen to reduce static

pressure load.

CONDENSER AIR DUCT INSULATION

The condenser air duct must be insulated on

indoor installations to prevent moisture condensa

tion on the unit panels during cold weather. Insu

late as follows:

1. If metal ductwork is used, insulation should be

applied on the inside of the duct. This insulation

should be extended to cover the inside of the

09BB duct flanges.

It is necessary to insulate the inside of the

ducts at the duct flanges to reduce heat loss

from the metal cabinet by conduction thru the

duct flanges and into the cold duct. Interior

insulation allows the metal duct to approach

room temperature. It also prevents condensa

tion from forming and collecting under the in

sulation which will occur with exterior duct

insulation.

2. If insulation is applied to the outside of the

metal duct, the inside must be insulated for a

length of ten inches from the unit (including

the duct flanges) or up to the flexible duct

vapor barrier on the outside which must be

tightly sealed to prevent condensation under

the insulation.