Installation, Positioning 09bb unit, Piping – Carrier 09BB User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTALLATION

Mounting Brackets

- Two mounting brackets are

supplied for mounting the 09 BB unit to the 50BB

unit (Fig. 4). These brackets have been designed

to provide adjustable heights for the 09BB to the

nearest 1/2 in. This is done by providing two sets

of mounting holes on the bracket, spaced 1-1/2 in.

apart. The upper mounting holes allow 09BB unit

height adjustment in 1-in. increments starting

1 ft 10-1/2 in. from the floor. The lower mounting

holes allow height adjustment in l-ir. increments

starting 2 ft from the floor.

Install brackets as follows:

1. Remove the top four retaining screws on each

side of the back panel of 50BB.

2. Select mounting holes and place bracket in

position. Install with retaining screws and

channel bolts in shipping holes (Fig. 4).

Install support bolts as shown in Fig. 3.

Install vibration isolators (supplied) in lowest

hole each side of 50BB back panel (Fig. 4). Re

move Tinnerman nut and install each vibration

isolator with 5/16 in. plain washer (supplied in

fastener package).

3.

4.

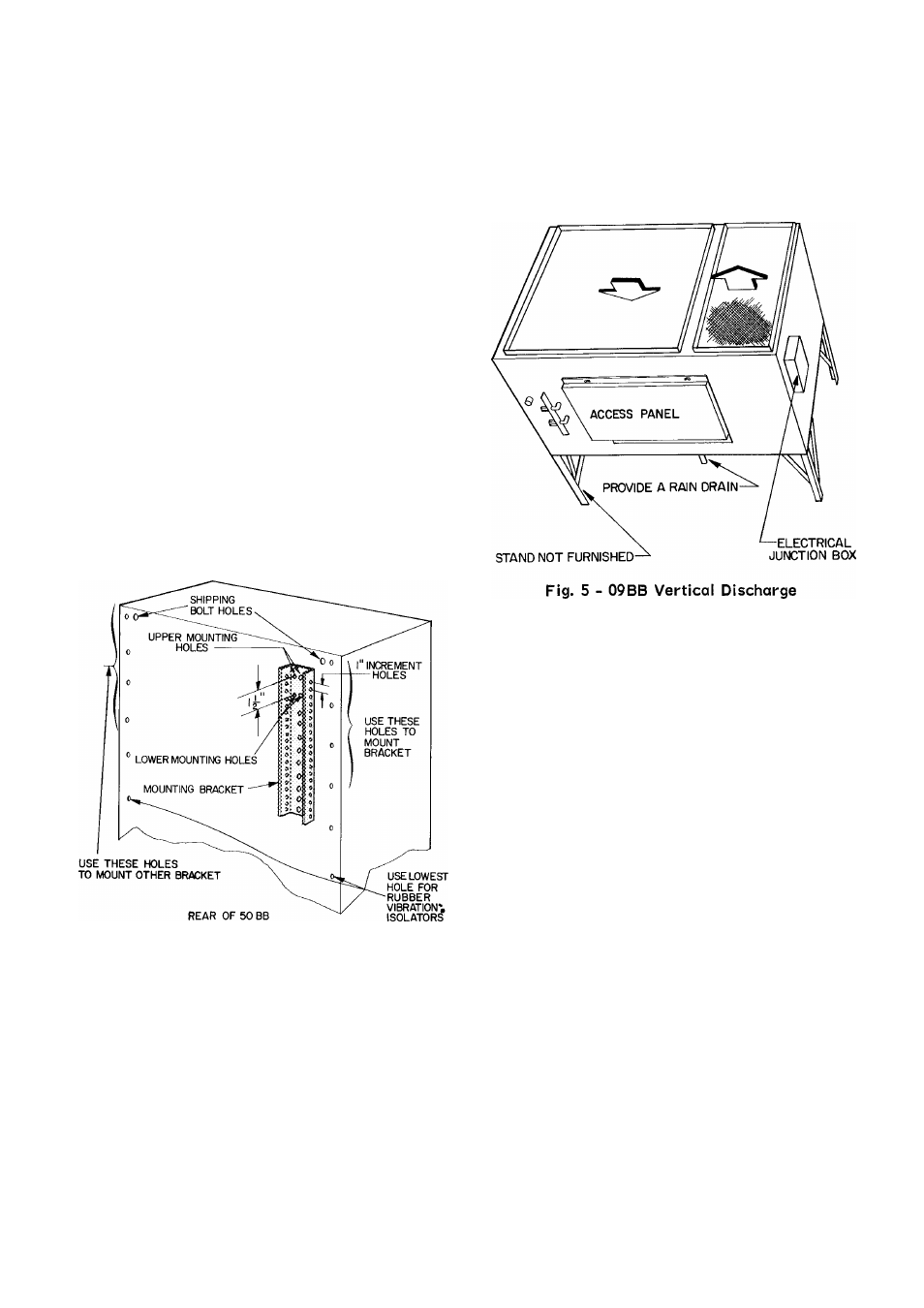

Fig. 4 - Installation of Mounting Brackets

Positioning 09BB Unit

refer to Fig. 3.

For typical installation

WARNING: The 50EB unit will not balance the

09BB unit without additional support.

Once 09BB unit has been positioned in the

mounting brackets, install locking bolts as shown

in mounting bracket detail.

Before sliding units into final position, check

for clearance to access panels, and service area

to install piping.

Vertical Discharge

- 09BB unit can be mounted as

shown in Fig. 5. It will be necessary to relocate

the electrical junction box either external to unit

(as shown) or on an interior panel.

Also, provide a rain drain on back of unit.

PIPING

09BB hot gas and liquid line piping is factory

supplied when field mounting the 09BB to the 50BB.

The preformed piping is arranged for various

mounting heights. Cut the vertical rise of tubes

for height adjustment. No bending is required.

09BB units are factory charged with refrig

erant. Liquid and hot gas lines are installed

as follows:

Compatible Fittings

- Liquid and hot gas lines are

installed from the 50BB unit to the 09BB unit with

Carrier compatible fittings and service valves.

These fittings may be used as sweat or mechanical

connections. Install either type as follows:

MECHANICAL CONNECTIONS

1. Cut tubing to length and remove burrs. Be care

ful not to expand tubing.

2. Remove plug from fitting and loosen nut one

turn.

3. Position tube. Remove cap and insert tube in

fitting to depth indicated on tag (1-1/4” depth

for 5/8” and 3/4” tube, 3/4” depth for 3/8”

and 5/16” tube).

4. Leave nut loose at condenser end of each tube.

Purge one line at a time using 50BB base unit

holding charge.

5. Tighten nut to a stop on unit fitting collar.

6. Open all service valves.