A caution, A check-up checklist – Carrier INFINITY ICS 58MVC User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

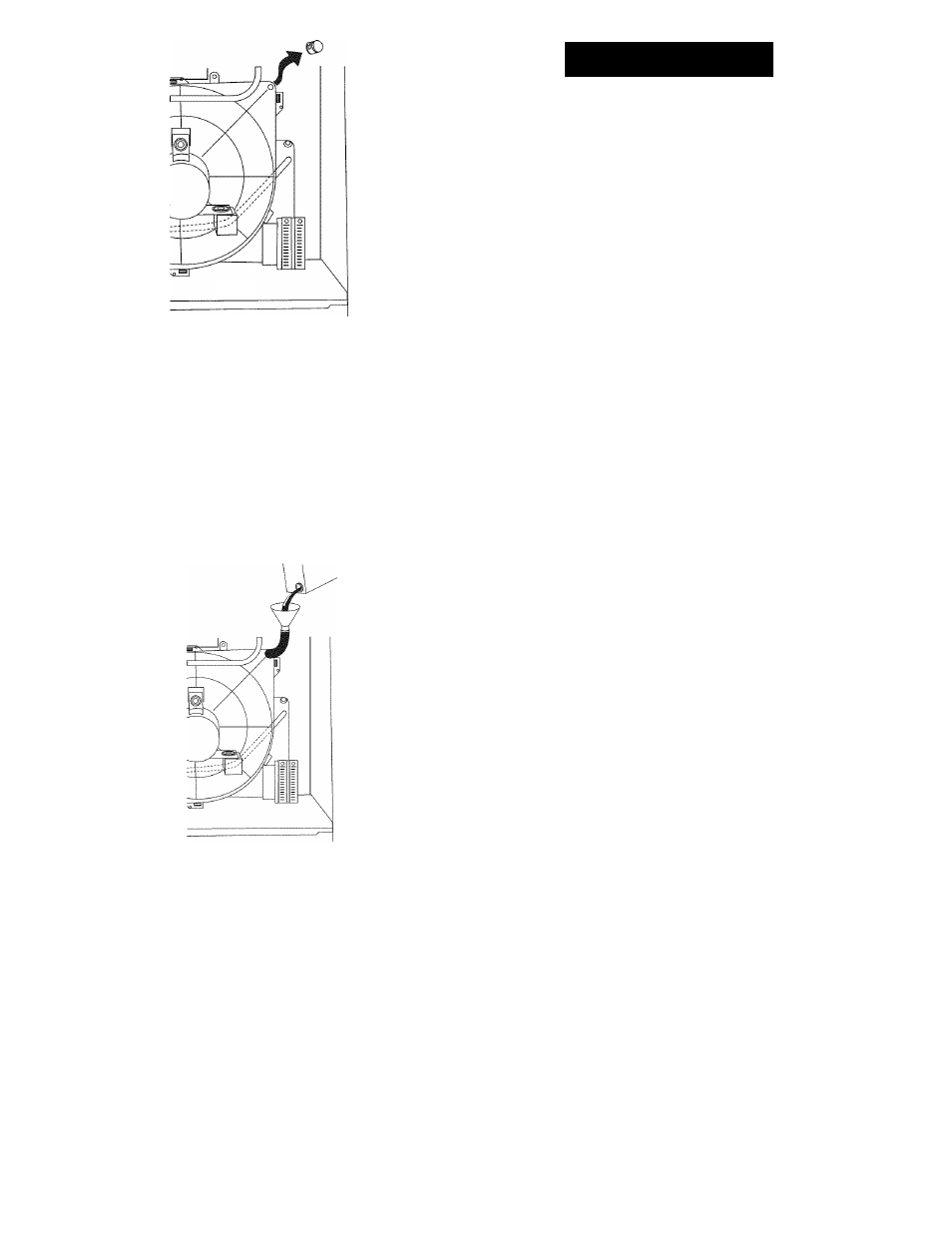

Fig. 35 - Upper Inducer Housing Drain

Connection Cap

3, Remove main furnace door. (See Fig. 19.)

4. Remove upper inducer housing drain connection cap. (See

Fig. 33.)

3. Connect field-supplied 1/2-in. ID tube to upper inducer

housing drain connection.

6. Insert field-supplied funnel into tube.

7. Pour 1 quart of antifreeze into funnel/tube. Antifreeze

should run through inducer housing, overfill condensate

trap, and flow into open field drain. (See Fig. 36.)

Fig. 36 - Pour Antifreeze

8. Remove funnel and tube from inducer housing and replace

drain connection cap and clamp.

9. Replace main furnace door. (See Fig. 30.)

10. Propylene glycol need not be removed before restarting

furnace.

A CAUTION

UNIT AND PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in damage to

unit components.

This furnace is designed for continuous return-air

minimum temperature of 60°F (13.6°C) db or intermittent

operation down to 33°F (12.8°C) db, such as when used

with a night setback thermostat. Return-air temperature

must not exceed 83°F (29.4°C) db.

If you choose to leave your furnace on during extended absences

do not set your thermostat lower than the limits shown in the

Caution box above.

To protect your property from damage from potential problems

due to unintended interruptions in utility services or other events,

it is recommended that you either winterize your plumbing

system or have someone check on your house regularly while

you are away.

Your dealer or a licensed plumber can give you additional advice

about winterizing your plumbing system.

A CHECK-UP CHECKLIST

Your furnace represents an important investment in your family’s

comfort and your home’s value. To keep it performing properly

and to prevent future problems, have a trained service specialist

give your furnace a professional check-up annually. The

following checklist can be used as a guideline to proper service:

•

Inspect all flue gas passages, burners, heat exchangers,

coupling box(es), and inducer assembly.

•

Inspect all combustion-air and vent piping inside

structure and vent pipe termination outside the

structure.

•

Check gas pipes leading to and inside your furnace for

leaks.

•

Inspect and clean the blower motor and wheel.

NOTE:

The inducer and blower motors are pre-lubricated and

require no additional lubrication. These motors can be identified

by the absence of oil ports on each end of the motor.

•

Inspect and change or clean air filters(s), if necessary.

•

Inspect all supply- and return-air ducts for

obstructions, air leaks, and insulation. Remedy any

problem when necessary.

•

Inspect the return-air duct connections(s) at the furnace

to ensure it is physically sound, sealed to the furnace

casing, and terminates outside the space containing the

furnace.

•

Inspect electrical wiring, connections, and components

for loose connections.

•

Perform an operational checkout to determine whether

your furnace is working properly and if it requires

adjustments.

•

Inspect all condensate drain tubes and condensate trap

assembly for leaks. The condensate removal system

should be cleaned annually by a qualified service

agency. Refer to the Service and Maintenance

Instructions for further information.

•

Examine the physical support of the furnace. Support

should be sound with no cracks, sagging, gaps, etc.

around the base.

•

Check furnace for any obvious signs of deterioration.

f2